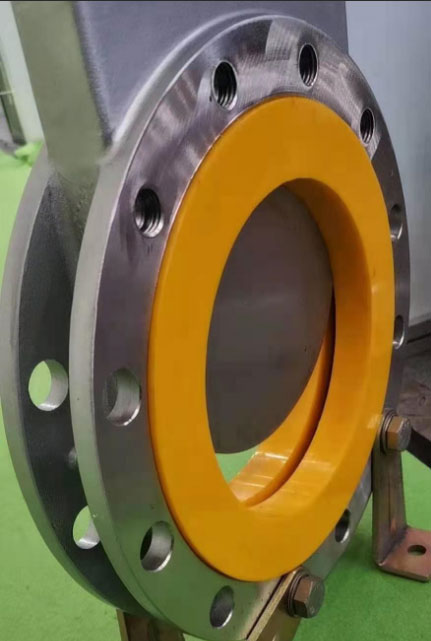

A PU (Polyurethane) lined knife gate valve is a specialized valve designed for handling abrasive, high-viscosity, or solid-laden media such as slurry, sand, pulp, or tailings.

The polyurethane liner provides exceptional wear resistance, impact strength, and corrosion protection, significantly extending the valve’s service life in demanding industrial environments.

This valve combines the proven reliability of a knife gate structure with the durability of PU elastomer, making it ideal for industries like mining, power generation, wastewater treatment, and paper & pulp processing.

Table of Contents

Toggle🧩 Working Principle

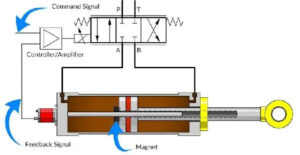

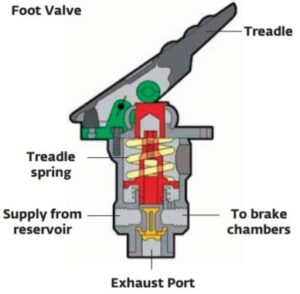

The PU lined knife gate valve operates through a linear motion of the gate (knife), which moves vertically through the flow path to open or close the passage.

When the valve is open, fluid flows freely; when closed, the sharp-edged gate cuts through solid materials and seals tightly against the resilient PU seat.

The polyurethane liner forms a full bore, corrosion-resistant channel that protects the valve body from abrasion and ensures a tight, bubble-free seal.

🔩 Key Features & Benefits

| Feature | Description |

|---|---|

| High Wear Resistance | PU lining protects against abrasive slurries and solid particles. |

| Tight Sealing Performance | Resilient polyurethane seat ensures zero leakage even under low pressure. |

| Full Bore Design | Unobstructed flow minimizes pressure loss and prevents clogging. |

| Replaceable Liner & Seat | Simplifies maintenance and extends valve service life. |

| Corrosion-Resistant Construction | Suitable for harsh environments and corrosive fluids. |

| Multiple Actuation Options | Available in manual, pneumatic, or electric operation. |

🧱 Applications

PU lined knife gate valves are widely used in abrasive and slurry-based industries, where traditional metal-seated valves wear out quickly.

🏗️ Mining & Mineral Processing: Tailings, slurry pipelines, concentrate transport.

⚡ Power Generation: Fly ash, bottom ash, gypsum slurry systems.

🧴 Chemical Processing: Corrosive and particle-laden fluids.

🌊 Wastewater Treatment: Sludge handling, thickened slurry, and grit removal.

📦 Pulp & Paper Industry: Paper stock, fiber slurry, recycled pulp.

🌾 Food & Beverage: Handling thick or abrasive liquids safely.

⚙️ Technical Specifications

| Parameter | Specification |

|---|---|

| Size Range | DN50 – DN1200 (2″ – 48″) |

| Pressure Rating | PN10 / PN16 / Class 150 |

| Body Material | Ductile Iron, Carbon Steel, Stainless Steel |

| Gate Material | AISI 304 / AISI 316 Stainless Steel |

| Liner/Seat Material | High-Density Polyurethane (PU) |

| Stem Material | Stainless Steel |

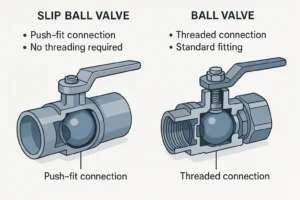

| End Connection | Wafer, Lug, or Flanged |

| Operation | Manual Handwheel, Gear, Pneumatic, or Electric |

| Temperature Range | -30°C to +80°C (PU material dependent) |

| Coating | Fusion Bonded Epoxy (FBE) or Custom Finish |

| Standards | MSS SP-81 / EN 593 / AWWA C520 |

💡 Advantages of PU-Lined Knife Gate Valves

✅ Long-lasting wear protection in slurry and abrasive service

✅ Leak-tight closure due to flexible PU seal

✅ Lightweight and corrosion-resistant compared to metal-seated valves

✅ Cost-effective maintenance — replaceable liner and seat components

✅ Excellent sealing performance under low-pressure conditions

✅ Ideal for high-cycle or on-off operation environments

🔧 Available Designs

Wafer Type PU Lined Knife Gate Valve – Compact and economical for space-limited installations.

Lug Type PU Lined Knife Gate Valve – Can be installed between flanges or as end-of-line service.

Flanged PU Lined Knife Gate Valve – For higher integrity sealing in heavy-duty systems.

Pneumatic Actuated PU Knife Gate Valve – Automated solution for frequent or remote operations.

🌍 Why Choose TOT Valve Solutions

TOT Valve Solutions manufactures and supplies PU lined knife gate valves engineered for severe abrasion and corrosion resistance.

With advanced polyurethane molding technology, precision machining, and international testing standards, our valves deliver long service life, low maintenance cost, and reliable sealing performance.

We provide:

🛠️ Custom sizes and pressure ratings

🌐 OEM & ODM manufacturing

📦 Global logistics support

🔍 Technical consultation for project-specific needs

📞 Contact Us

Looking for a durable solution for abrasive or slurry applications?

Our PU-lined knife gate valves provide unmatched performance in challenging environments.

👉 Contact TOT Valve Solutions today for product datasheets, technical support, or a customized quotation.