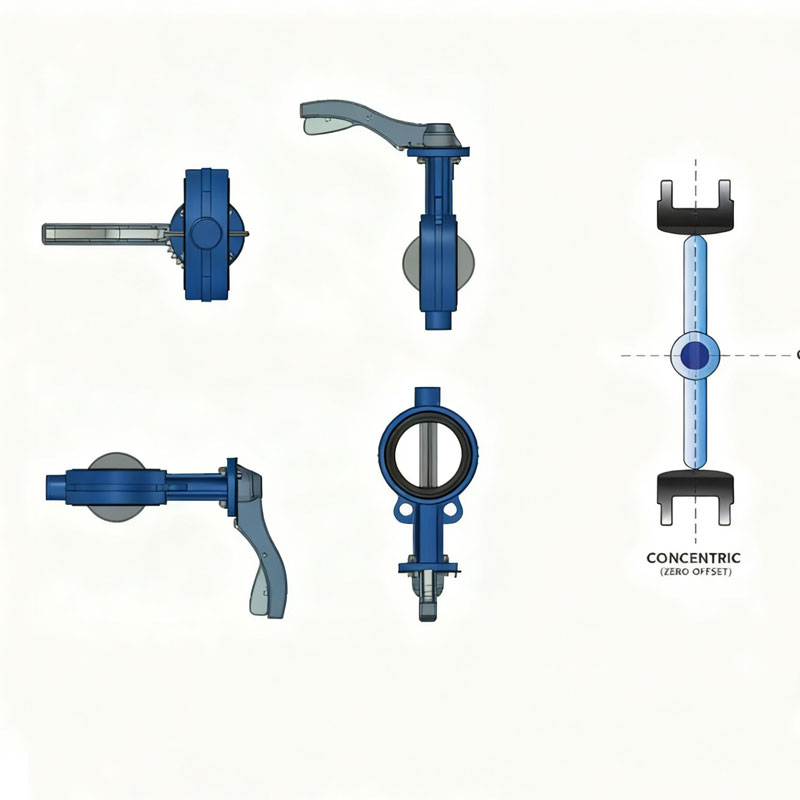

Centerline (Concentric) Butterfly Valves

The Centerline Butterfly Valve (also known as a Concentric Butterfly Valve) is a foundational component in piping systems, primarily used for on/off service and throttling (flow control). It is characterized by its simple design where the valve stem axis, the disc center, and the valve body center are all positioned on the same axis.

While traditional Centerline valves use soft materials like rubber or PTFE for sealing and are often limited in high-temperature, high-pressure, corrosive, and abrasive environments, modern designs incorporate advanced features to enhance performance and service life.

Core Design Philosophy

- Concentric Design: The primary characteristic where the stem, disc, and body centers are co-axial.

- Sealing: Primarily utilizes a Soft Seat design (resilient seated) for achieving permanently tight closure.

- Simplicity & Reliability: Features no pins connection between the disc and the shaft, resulting in only two parts in contact with the medium (disc and seat), which maximizes corrosion resistance.

- Maintenance: Available as a maintenance-free version and featuring a replaceable cartridge seat design with a solid backup ring to minimize lifetime costs and allow for the best fit, even for vacuum applications.

Key Design Features

| Feature Highlight | Benefit |

| Minimal Wetted Parts | Only the disc and seat contact the medium, with no exposed metal-to-metal contact points, ensuring maximum corrosion resistance. |

| Self-Centering Disc | The smooth finish and spherical edge of the disc reduce wear and resist corrosion and abrasion. |

| Vacuum Performance | The replaceable cartridge seat and solid backup ring design ensures optimum operation under vacuum conditions. |

| Actuator Adaption | Features a standardized top flange for direct mounting of pneumatic, electric, or manual actuators without the need for additional brackets. |

| Safety | Includes a blow-out proof shaft for enhanced operator safety. |

| Flow Control | Usable as a quick-closing valve and provides excellent fluid characteristics. |

| Structural Integrity | Short face-to-face dimension (compact design). |

Technical Specifications

| Parameter | Specification |

| Size Range (DN/Imperial) | DN 40 up to DN 1400 / $1\frac{1}{2}”$ up to $56”$ |

| Pressure Ratings | PN10, PN16, ASME Class 150 |

| Temperature Range | $-30^\circ\text{C}$ ($-22^\circ\text{F}$) up to $200^\circ\text{C}$ ($392^\circ\text{F}$) (dependent on material/seat selection) |

| Sealing Type | Soft Seat (Resilient Seated) |

| Connection Types | Wafer type, Lug type, Wafer type with centering lugs, Double flanged |

| Body Lining | Replaceable body lining with firm back-up ring |

Connection Methods

Centerline Butterfly Valves are classified by how they connect to the pipeline:

- Wafer Butterfly Valve: Clamped between two flanges in the piping system.

- Lug-Type Butterfly Valve: Features threaded bolt holes (lugs) around the perimeter, allowing it to be securely bolted to both flanges and used as an end-of-line valve (at reduced pressure).

- Flanged Butterfly Valve (Double Flanged): Features integral flanges on the valve body for direct bolting to corresponding pipe flanges.

Special Options

- Trunnion Bearing: An additional bearing available for high cycling applications to handle increased lateral forces and reduce friction.

- Shaft Extensions: Used when the valve needs to be operated remotely or below insulation.

Centerline butterfly valves are widely applied across various fields, including Petroleum, Chemical, Metallurgy, and Hydropower, providing an efficient, reliable, and cost-effective solution for fluid control.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.