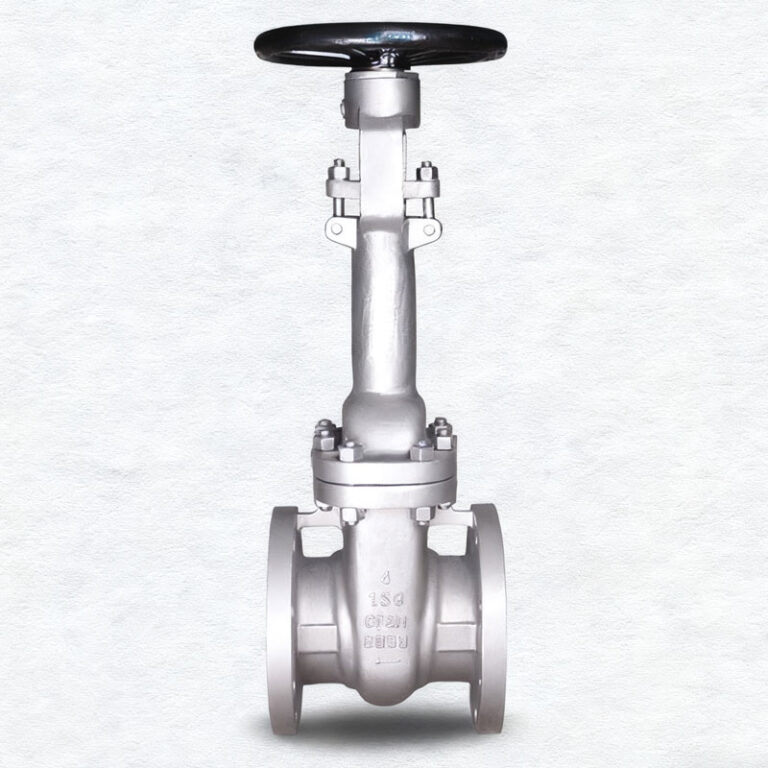

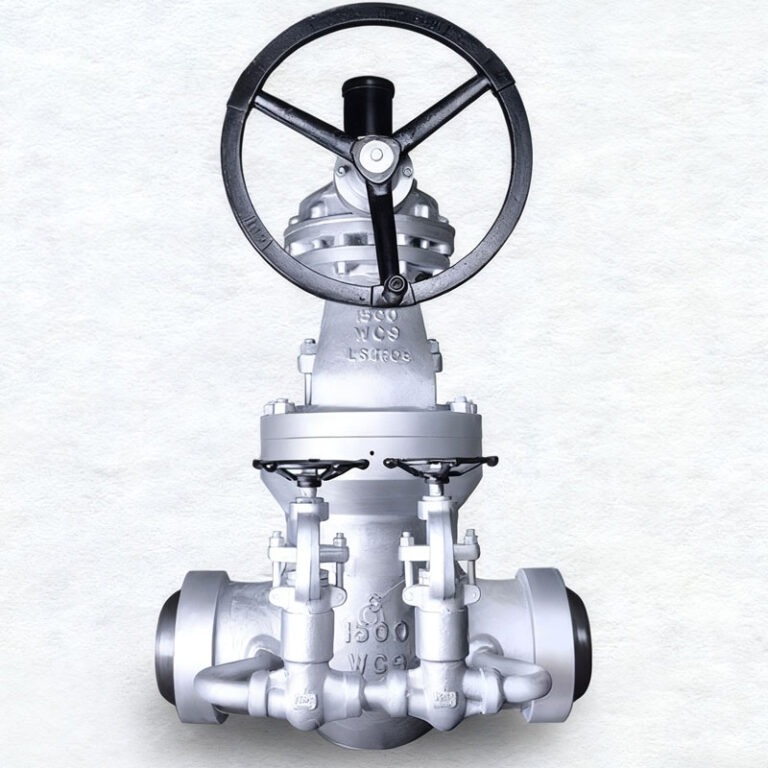

Zirconium Alloy OS&Y Rising Stem Flanged Wedge Gate Valve

This product is a premium Zirconium Alloy Gate Valve, featuring an Outside Screw and Yoke (OS&Y) rising stem and a wedge gate design. This straight-through, flanged valve is specifically engineered for severe chemical services where standard materials fail, offering superior resistance to highly corrosive media.

Product Overview

The Zirconium Gate Valve is an essential component used for on/off service (to fully cut off or fully connect the flow) in pipelines carrying highly aggressive media like aqua regia and other strong oxidizing corrosives. The body’s construction utilizes Zirconium or Zirconium Alloy for maximum corrosion immunity, while the design adheres to rigorous international industry standards.

Type: OS&Y Rising Stem, Wedge Gate, Straight-Through, Flanged.

Actuation: Manual (Handwheel).

Purpose: Isolation (Cut-off) of flow.

Key Material: Zirconium Alloy (Zirconium is known for exceptional corrosion resistance, particularly to strong acids and bases).

Core Technical Specifications

The specifications below represent a typical configuration; customization is available.

| Parameter | Specification | Notes |

| Nominal Size | DN100 (Standard) | Available range: DN25 – DN500 ($1”$ – $20”$) |

| Nominal Pressure | Normal Pressure (PN16 – PN63 available) | Pressure class range PN16-63 (e.g., ASME Class 150-600) |

| Working Temperature | Normal Temperature | Specific range depends on final material selection. |

| Connection Type | Flanged | Highly reliable connection for high-integrity chemical lines. |

| Body Material | Zirconium Alloy (Body material in table says Stainless Steel, but product is Zirconium Alloy) | Zirconium provides exceptional corrosion resistance. |

| Sealing Type | Hard Seal (Body Sealing) | Wedge structure for reliable shut-off. |

| Flow Direction | Unidirectional | Standard gate valve operation. |

| Operation | Manual (Handwheel) | Other driving methods available upon request. |

Principle and Features

Gate valves operate by lifting a rigid or flexible wedge (gate) perpendicular to the flow path. They are designed for tight shut-off and should only be used in the fully open or fully closed position.

Key Features

- Exceptional Corrosion Resistance: Primarily designed for highly corrosive media such as aqua regia, strong oxidizing agents, and concentrated acids.

- Low Flow Resistance: The straight-through, full-bore design minimizes fluid resistance (low pressure drop) when fully open.

- Bidirectional Flow: The design is generally symmetrical, allowing media to flow in either direction, simplifying installation.

- Clear Position Indication: The OS&Y Rising Stem design allows for visual confirmation of the valve’s open or closed status.

- Reduced Water Hammer Risk: The longer opening/closing time minimizes the risk of water hammer phenomena.

Limitations (Inherent to Gate Valves)

- Cannot be used for throttling or regulation.

- Larger size and required operational height (due to the rising stem).

- Seating surfaces are susceptible to erosion and scratching, making maintenance challenging.

Applicable Industries

The Zirconium Gate Valve is crucial in industries dealing with media that severely corrode conventional stainless steel or alloy valves:

- Chlor-Alkali Industry

- Soda Ash Industry

- Pharmaceutical and Fine Chemical

- Fertilizer Industry

- Textile Fiber Synthesis and Dyeing

- Nitric Acid Industry

- Production of Basic Organic/Inorganic Salts

Applicable Standards

This valve is manufactured and tested according to recognized international standards:

- Design and Manufacturing: API 600 or API 6D (Cast Steel: API 602)

- Face-to-Face Dimension: ASME B16.10

- Flange Connection Dimensions: ASME B16.5 (NPS $< 24$) or ASME B16.47 (NPS $> 26$)

- Pressure-Temperature Ratings: ASME B16.34

- Inspection and Test: API 598 or API 6D or API 600

For severe corrosive service requiring reliable, manual isolation, inquire about our Zirconium Alloy Gate Valve series.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.