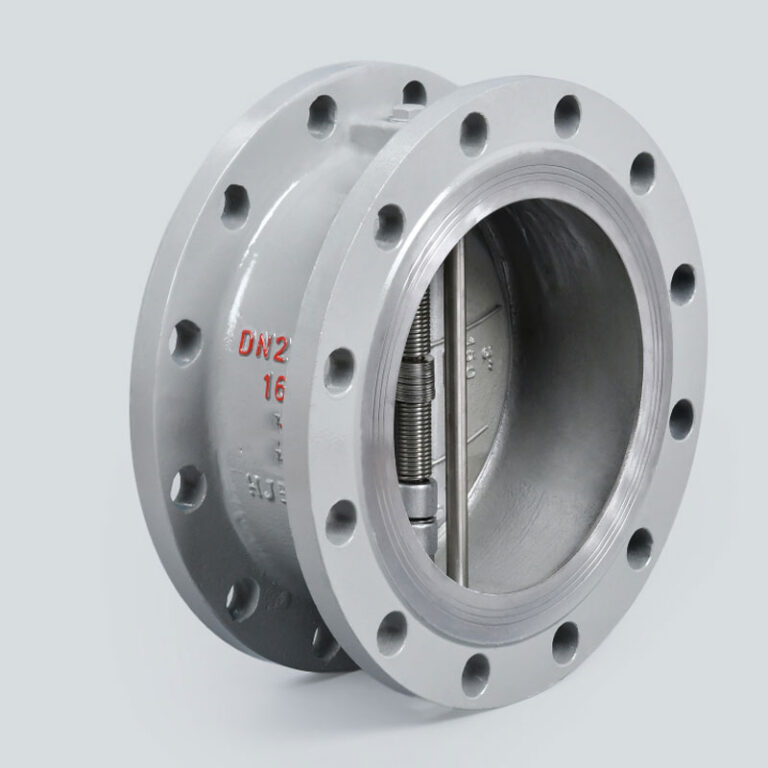

Stainless Steel Wafer Swing Flapper Check Valve for Potable Water

This describes a Wafer Type Swing Flapper Check Valve (often referred to as a wafer check valve due to its thin profile) manufactured for applications including potable water systems. Its primary advantage is its slim profile and light weight, which saves installation space and simplifies maintenance.

Key Features and Design

- Type: Swing Flapper Check Valve (Wafer Type).

- Design: Features a slim shape and simple structure where the disc swings open with forward flow and relies on gravity and back pressure to quickly close, preventing reverse flow.

- Space Saving: Ideal for installation in limited spaces due to its compact, wafer-style body which fits between two pipe flanges.

- Aesthetic and Practical: Offers a beautiful appearance, is lightweight, and easy to install.

- Function: Automatically permits flow in one direction and prevents backflow, protecting pumps and other equipment from water hammer.

Technical Data and Material Selection

| Parameter | Specification | Notes |

| Nominal Pressure (PN) | 1.0, 1.6, 2.5, 4.0 MPa | Corresponds to PN10 to PN40 ratings. |

| Shell Testing Pressure | 1.5, 2.4, 3.75, 6.0 MPa | Confirms pressure integrity of the valve body. |

| Seal Testing Pressure | 1.1, 1.76, 2.75, 4.4 MPa | Confirms sealing capability against reverse flow. |

| Suitable Temperature | <400(Hard seal) <120(<250)(Soft seal) | Temperature suitability depends on seal type chosen. |

| Suitable Mediums | Oil, Water, Acid and Alkali Liquid | Broad compatibility, making it suitable for potable water and chemical fluids. |

Material of Main Parts

For Potable Water and general corrosion resistance, the valve should utilize the following:

| Part Name | Standard Materials Available | Recommended for Potable Water / Corrosion Resistance |

| Valve Body, Valve Disc | Carbon Steel, Stainless Steel, Copper | Stainless Steel (e.g., SS304/SS316) is recommended for long-term corrosion resistance in water systems. |

| Seat Ring | NBR, EPDM, PTFE | EPDM is typically preferred for cold and hot water applications, including potable water, due to its chemical resistance and certification compatibility. |

Applications

This valve is widely applied across various industrial sectors:

- Water Supply Systems (Potable Water): Ensuring flow integrity and preventing contamination from backflow.

- Petroleum and Chemical Industries

- Metallurgy

- General Industrial Fluid Control

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.