Table of Contents

ToggleWhat Is a Plug Valve?

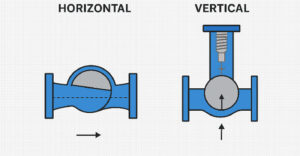

A plug valve is a type of quarter-turn valve that controls the flow of fluid by rotating a cylindrical or conical plug inside the valve body. The plug has one or more hollow passageways that align with the flow path when open, allowing the medium to pass through.

When the plug is turned 90 degrees, the passage is blocked, and the valve is closed, stopping the flow completely.

Plug valves are among the earliest valve designs and are widely used for shut-off and flow diversion. With proper design and modification of the plug port shape, they can also be used for throttling applications.

Because the sealing surfaces of a plug valve move with a wiping action during operation, these valves are particularly suitable for media containing suspended particles, slurries, or viscous fluids.

Working Principle of Plug Valve

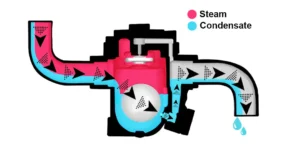

The plug inside the valve is rotated around its stem axis to connect or disconnect the flow path.

When the plug’s passage aligns with the pipeline, the valve is fully open; when it is perpendicular, the valve is fully closed.

This simple rotational motion allows for:

Quick operation (just a 90° turn)

Bidirectional flow capability

Reliable shut-off performance when properly sealed

For conical plug valves, a compressive force is applied along the stem axis to press the plug tightly against the valve seat, ensuring tight sealing performance under pressure.

Main Components of a Plug Valve

A standard plug valve consists of the valve body, plug, and gland assembly.

Depending on the design, some models also include packing materials or lubrication systems for easier operation and better sealing.

1. Valve Body

The valve body is usually cast and can be designed in straight-through, three-way, or four-way configurations:

Straight-through type: Used mainly for on/off isolation.

Three-way and four-way types: Designed for flow diversion or distribution, with L-shaped or T-shaped plug passages to redirect the fluid flow.

2. Plug

The plug serves as the closing element and can be cylindrical or conical.

Its port shape may be rectangular, trapezoidal, or circular, depending on the flow characteristics required.

A properly machined plug with smooth sealing surfaces ensures tight closure and minimal leakage.

3. Packing and Gland

To prevent leakage along the stem, a packing gland compresses sealing materials such as PTFE or graphite around the stem.

Some plug valves include lubrication systems to reduce torque and wear during operation.

Advantages of Plug Valves

Simple and Compact Design

Plug valves have fewer parts, are lightweight, and take up minimal installation space.Low Flow Resistance

The internal passage is generally straight and smooth, minimizing pressure drop and ensuring high flow efficiency.Quick Operation

Only a quarter-turn (90° rotation) is required to open or close the valve, making it ideal for systems that need fast shut-off or frequent operation.Bidirectional Flow Capability

The valve allows flow in either direction, adding flexibility to pipeline design.Suitable for Dirty or Slurry Media

The wiping action between sealing surfaces helps prevent clogging and ensures reliable performance even with suspended solids or viscous media.

Disadvantages of Plug Valves

High Operating Torque

Due to the large contact area between the plug and the valve body, higher torque is required for operation — particularly in large-diameter valves.Seal Wear and Deformation

The conical sealing surfaces may wear or deform under high temperature or prolonged use, leading to possible leakage or jamming.Complex Machining Requirements

The sealing surfaces must be precisely machined and highly polished, which increases manufacturing difficulty and cost.Maintenance Challenges

Once worn, the sealing surface is difficult to repair, requiring regrinding or replacement.

Applications of Plug Valves

Plug valves are widely used in industries where reliable shut-off and quick operation are essential, including:

Oil and Gas Pipelines

Petrochemical and Chemical Processing

Water and Wastewater Treatment

HVAC Systems and Utilities

Food and Beverage Processing

Power Generation Plants

They are ideal for handling gases, oils, water, slurries, and mildly corrosive media.

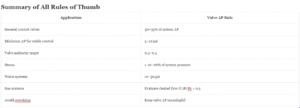

Comparison: Plug Valve vs. Ball Valve

| Feature | Plug Valve | Ball Valve |

|---|---|---|

| Operating Mechanism | Rotating plug (cylindrical/conical) | Rotating ball with bore |

| Flow Control | Good (can throttle flow) | Excellent for on/off only |

| Torque | Higher | Lower |

| Maintenance | More complex | Easier |

| Application | Slurries, viscous fluids | Clean fluids, gases |

Conclusion

A plug valve is a reliable and versatile valve type suitable for on/off, diverting, and throttling applications.

Its compact design, low flow resistance, and fast quarter-turn operation make it a popular choice across various industries.

However, when torque, sealing wear, or high-temperature performance is a concern, it’s important to consider lubricated plug valves or sleeved plug valve designs for longer service life and smoother operation.

At TOT Valve, we offer a full range of industrial plug valves designed for durability, performance, and precision — from cast steel and stainless steel to PTFE-lined and lubricated types.

Contact TOT Valve today to learn how our plug valve solutions can enhance your pipeline reliability and efficiency.