Pressure Reducing Valve (PRV)

The Pressure Reducing Valve (PRV) is a fundamental control device engineered to manage fluid dynamics, guaranteeing a consistent and safe downstream pressure regardless of fluctuations in the upstream supply. This valve acts as a self-regulating barrier, enhancing the safety, efficiency, and reliability of complex fluid systems across diverse industrial and commercial sectors.

⚙️ How the PRV Delivers Stable Control

The PRV operates using the energy of the fluid itself via an integrated spring-loaded diaphragm or piston mechanism.

- When Inlet Pressure Rises: The high pressure forces the diaphragm/piston to compress the spring and move the valve plug toward the seat. This action reduces the flow passage, effectively throttling the fluid and automatically lowering the outlet (downstream) pressure back to the desired setpoint.

- When Inlet Pressure Drops: The spring force overcomes the reduced inlet pressure, moving the plug away from the seat. This increases the flow passage, allowing more fluid through to maintain the stable outlet pressure.

This continuous, automatic modulation ensures your system is protected from damaging pressure spikes and maintains optimal operating conditions.

✅ Key Applications and Industries

The PRV is an essential component providing critical pressure control in high-demand environments:

- Water Supply & Sewage: Protecting residential, commercial, and municipal piping from excessive street pressure.

- HVAC Systems: Maintaining regulated pressure in chiller and boiler loops.

- Food & Beverage: Ensuring stable pressure for processing lines and equipment protection.

- Chemical/Petrochemical Processing: Critical for regulating fluid inputs to reactors and sensitive instruments.

- Power and Utilities: Controlling fluid inputs in high-pressure steam and water systems.

- Ship Building & Pulp and Paper: Used in various utility and process control lines.

🛠️ Standard Materials & Construction

Constructed for durability and performance in demanding fluid environments:

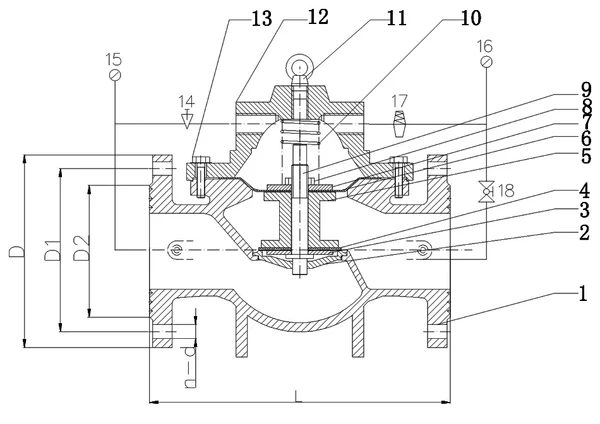

| NO. | PART NAME | MATERIAL | Function/Notes |

| 1 | Body | Cast Iron (CI) | High strength and rigidity for flanged connection. |

| 2, 17, 18 | Seat, Pilot Valve, Ball Valve | Brass | Corrosion resistance and precise control in smaller components. |

| 5, 12 | Disc, Bonnet | Ductile Iron (DI) | Superior strength and ductility over standard cast iron. |

| 4, 6 | Seal, Diaphragm | EPDM | Flexible elastomer suitable for water and many non-petroleum fluids. |

| 8, 10, 13 | Nut, Spring, Bolts | Stainless Steel | Corrosion resistance and reliable mechanical function. |

📊 Standard of Implementation & Dimensions

| Property | Details |

| Type | Flanged |

| Flange Standards | DIN, BS, UNI, ISO, ANSI, AS, JIS (Wide global compatibility) |

| Working Pressure | PN16 (200PSI) |

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.