A check valve—also known as a non-return valve (NRV)—has one job: to prevent backflow. However, one of the most common causes of premature valve failure and system noise is incorrect installation orientation.

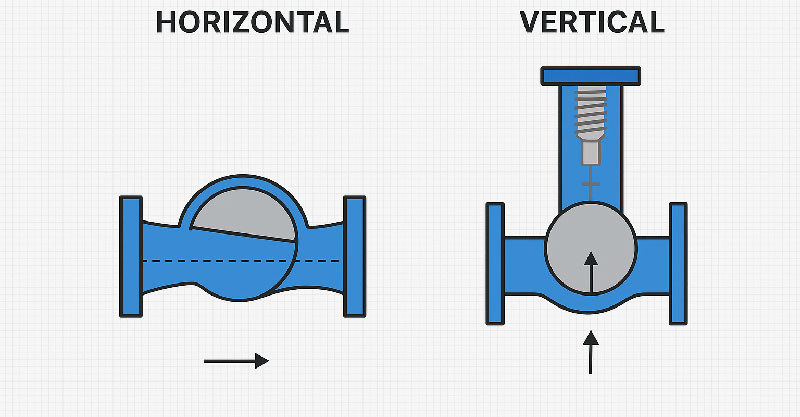

You cannot simply flip a horizontal check valve and install it vertically without understanding how gravity and spring tension affect the seal. This article explains the critical differences between horizontal and vertical check valves and the “Golden Rules” of installation you must follow to protect your pumps.

Table of Contents

Toggle1. The Gravity Factor: Horizontal Installation

Horizontal check valves are the industry standard for most process lines. They are designed to operate in a strictly horizontal plane.

How They Work: Most horizontal valves, like the Swing Check, rely on a combination of gravity and backpressure. When flow stops, the weight of the disc causes it to drop or swing back onto the seat.

The Constraint: These valves must be installed “level.” If a horizontal swing check is installed at an incline, the disc may not seat properly, leading to bypass leakage even when the valve is “closed.”

Pro Tip: For horizontal swing check valves, always ensure the hinge pin is perfectly horizontal to prevent uneven wear on the seat.

2. The Spring Requirement: Vertical Installation

Vertical check valves are essential for risers and deep-well pump applications. However, they are mechanically more complex than their horizontal counterparts.

The Flow Rule: Vertical check valves are designed for Upward Flow ONLY. Fluid must move from bottom to top to lift the disc.

The Spring Mechanism: Unlike horizontal valves, vertical NRVs almost always require a spring-assist. Why? Because gravity works against the disc in a vertical line. A spring ensures the valve “snaps” shut the millisecond the pump stops, preventing a long column of water from crashing back down.

The “Downflow” Warning: Never install a standard check valve in a downward-flow vertical pipe. Gravity will pull the disc open, rendering the valve useless and inviting catastrophic backflow.

3. Comparison Table: Orientation & Performance

| Feature | Horizontal Check Valve | Vertical Check Valve |

| Primary Sealing Force | Gravity + Backpressure | Spring Tension + Backpressure |

| Flow Path | Straight or Slightly Curved | Straight (In-line) |

| Water Hammer Risk | Higher (Slower closure) | Lower (Spring closes pre-emptively) |

| Cracking Pressure | Very Low | Higher (Must overcome spring + gravity) |

| Serviceable Parts | Usually accessible from the top | Often requires removal from line |

| Typical Design | Swing or Lift type | In-line Spring-Loaded or Silent type |

4. Operational Differences: Cracking Pressure

One factor engineers often forget is Cracking Pressure—the minimum pressure required to open the valve.

In a Horizontal Valve, cracking pressure is minimal because the pump only needs to move the weight of the disc.

In a Vertical Valve, the pump must overcome the weight of the disc PLUS the spring tension PLUS the weight of the water column. Ensure your pump head is sized correctly to account for this higher resistance, or you may face “fluttering” (where the valve vibrates because it can’t stay fully open).

5. Typical Applications

Horizontal Applications

Main water distribution lines

Pump discharge in flat terrain

Steam and condensate return lines

Large-diameter sewage pipes

Vertical Applications

Sump pump discharge

High-rise building water risers

Well water extraction

HVAC cooling towers

6. Advantages and Critical Limitations

| Type | Pros | Cons |

| Horizontal | Low pressure drop; easy maintenance; cheaper for large sizes. | Prone to “slamming”; requires significant footprint. |

| Vertical | Eliminates water hammer; saves space; operates silently. | Limited flow capacity; higher cracking pressure; strictly for up-flow. |

7. How to Choose: The Decision Checklist

To choose the right orientation, ask your team these three questions:

Is my flow moving up or across? Upflow requires a spring-loaded vertical valve. Horizontal requires a gravity-assisted valve.

Is there a risk of Water Hammer? If you have a long vertical column of water, use a Silent Vertical Check Valve to prevent the “bang” when the pump stops.

What is my pump’s head capacity? If your pump is weak, a high-tension spring in a vertical valve might restrict your flow too much.

Conclusion

Orientation is not a suggestion; it is a functional requirement. Using a horizontal swing check in a vertical line will lead to leakage, while ignoring the spring requirement in a vertical riser can lead to pipe bursts. Always match your valve’s internal mechanism to the direction of your piping.