A butterfly valve is a quarter-turn rotary valve used to regulate or isolate the flow of fluids such as water, air, gas, oil, or slurry within a piping system. It is one of the most commonly used flow control devices in industrial applications due to its simple design, compact structure, and cost-effectiveness.

Table of Contents

Toggle1. Structure and Working Principle

The butterfly valve consists of four main parts:

Body – The outer casing that fits between two pipe flanges.

Disc – The rotating element (similar to a butterfly wing) that opens or closes the valve.

Stem (or Shaft) – Connects the actuator or handle to the disc, allowing rotation.

Seat – Provides sealing between the disc and valve body to prevent leakage.

The working principle is straightforward. When the handle or actuator rotates the stem by 90 degrees, the disc either aligns parallel to the fluid flow (fully open) or perpendicular to it (fully closed). Intermediate positions allow for flow regulation.

2. Types of Butterfly Valves

Butterfly valves come in several designs depending on their construction and application:

Wafer Type: The most common type, clamped between two flanges with bolts. It is lightweight and easy to install.

Lug Type: Features threaded inserts (lugs) on both sides, allowing one side of the pipeline to be removed without affecting the other.

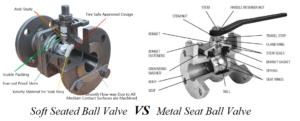

Double Eccentric (High-Performance): The disc shaft is slightly offset, reducing wear on the seat and improving sealing at higher pressures.

Triple Eccentric (Metal Seated): Used for high-temperature and high-pressure applications, offering tight shutoff and durability.

3. Materials

The materials of butterfly valves vary depending on the medium and operating conditions:

Body: Cast iron, ductile iron, stainless steel, carbon steel, PVC, or bronze.

Disc: Stainless steel, aluminum bronze, or coated steel.

Seat: EPDM, PTFE, NBR, or metal depending on pressure, temperature, and chemical compatibility.

4. Advantages of Butterfly Valves

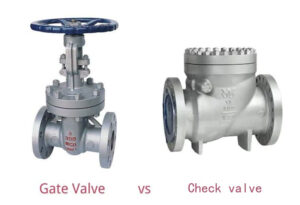

Compact and Lightweight: Requires less space and support compared to gate or globe valves.

Quick Operation: Quarter-turn movement ensures fast opening and closing.

Low Pressure Drop: When fully open, the flow path is streamlined with minimal resistance.

Cost-Effective: Simple construction and easy maintenance reduce installation and operating costs.

Versatile: Suitable for liquids, gases, and slurries in various industries.

5. Applications

Butterfly valves are used in a wide range of industries, including:

Water and Wastewater Treatment – For flow control in large pipelines.

HVAC Systems – Regulating air or water flow in heating and cooling systems.

Chemical and Petrochemical Plants – Handling corrosive or non-corrosive fluids.

Power Generation – Used in cooling water, fuel, and steam systems.

Food and Beverage Processing – For sanitary and clean applications.

6. Conclusion

A butterfly valve offers a reliable, efficient, and economical solution for fluid flow control. With options ranging from soft-seated to high-performance triple-offset designs, it can be tailored to almost any application. Its simplicity, fast operation, and wide material selection make it one of the most essential valves in modern industrial and commercial systems.