A ball sewage check valve (also known as a ball-type check valve) is a key component in wastewater pipeline systems, designed to prevent backflow and ensure one-way fluid movement.

Depending on the system’s pressure, pipe size, and maintenance requirements, these valves can be connected using several different methods.

Below are the five most common connection types and their respective features, advantages, and installation considerations.

Table of Contents

Toggle1. Threaded Connection

Best for: Small-diameter pipes (DN15–DN50), low-pressure systems, or limited installation spaces.

Features:

Connected by internal (FPT) or external (MPT) threads that are screwed directly into the pipe.

Simple and low-cost installation.

Typically sealed using PTFE tape or thread sealant to prevent leakage.

Notes:

Ensure thread compatibility (e.g., NPT, BSPT, or other standards).

Frequent disassembly may wear the threads and reduce sealing performance.

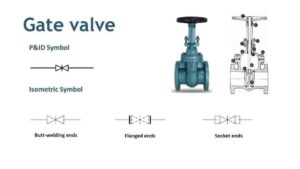

2. Flanged Connection

Best for: Medium to large pipe diameters (DN50 and above), high-pressure systems, or installations requiring frequent maintenance.

Features:

The valve body has flanges at both ends, connected to the pipeline with bolts and a gasket (rubber, PTFE, or graphite).

Excellent sealing performance, strong pressure resistance, and easy to remove for maintenance.

Notes:

Flange standards must match (e.g., ANSI, DIN, GB) and pressure ratings (PN10, PN16, etc.).

During installation, ensure precise alignment and even bolt tightening to avoid leaks.

3. Wafer Connection

Best for: Compact systems where installation space is limited.

Features:

The valve is clamped between two pipe flanges using long bolts, without its own flanged ends.

Lightweight, cost-effective, and easy to install.

Notes:

Must be aligned concentrically with the pipe flanges to prevent uneven stress on the sealing surface.

Generally lower pressure resistance compared to flanged connections.

4. Socket Weld Connection

Best for: High-pressure, small-diameter pipelines (DN ≤ 50) that require excellent sealing, such as chemical or petrochemical systems.

Features:

The valve has a socket end; the pipe is inserted and welded to form a permanent joint.

Offers superior sealing and pressure resistance.

Notes:

Requires skilled welding to prevent deformation or valve damage.

Not suitable for pipelines that need frequent disassembly or inspection.

5. Quick Coupling Connection

Best for: Temporary systems, mobile equipment, or portable wastewater units requiring fast assembly and disassembly.

Features:

Uses clamps, latches, or couplers for tool-free installation.

Very easy to install or remove.

Notes:

Limited sealing and pressure resistance.

Regularly check O-rings or seals for aging or wear.

Suitable for low-pressure, non-corrosive media only.

Selection Guide

When choosing a connection type for a ball sewage check valve, consider the following factors:

| Condition | Recommended Connection |

|---|---|

| Fluid with solids or debris | Flanged or Wafer type (easy cleaning) |

| High pressure (>1.6 MPa) | Flanged or Socket Weld |

| Frequent maintenance required | Flanged or Threaded |

| Cost-sensitive, small system | Threaded |

| Limited installation space | Wafer type |

Installation Tips

Flow Direction: Always follow the arrow on the valve body — it must match the actual fluid direction.

Orientation: For horizontal pipes, the valve axis should be vertical. In vertical pipes, flow must go from bottom to top.

Avoid turbulence: Do not install the valve directly after a pump or near an elbow; this helps reduce water hammer effects.

Conclusion

Choosing the correct connection method for a ball sewage check valve directly affects its performance, sealing reliability, and service life.

For small low-pressure systems, threaded connections are cost-effective; for large, high-pressure, or frequently serviced systems, flanged connections are ideal.

Proper installation according to flow direction and pressure rating ensures long-lasting, reliable backflow prevention in any wastewater application.