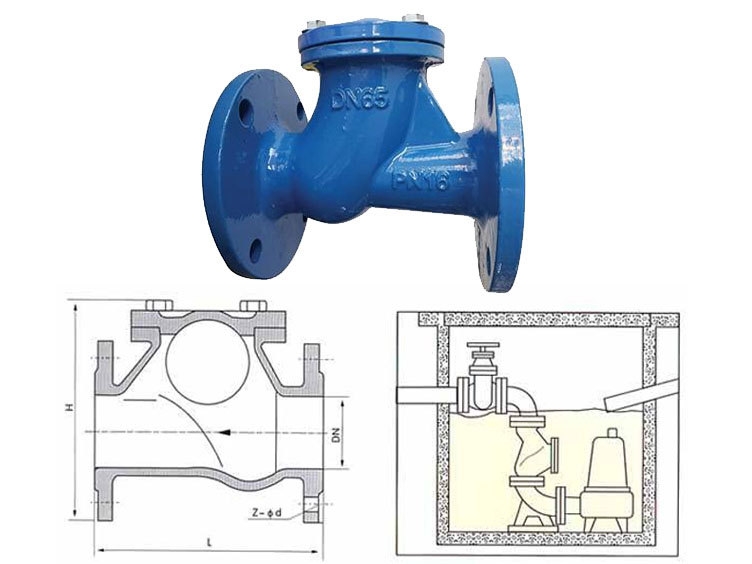

Sewer Pump Check Valve: Rolling Ball Type

The Rolling Ball Type Sewer Check Valve (also known as a Ball Check Valve for pressure drainage) is a specialized non-return valve engineered specifically for wastewater and sewage applications. It is the ideal discharge check valve for submersible sewage pumps, designed to handle high-viscosity fluids and suspended solids without clogging, which is a major drawback of general-purpose check valves.

The unique rolling ball mechanism and full-bore structure ensure reliable, maintenance-free operation in contaminated lines.

⚙️ Technical Specifications

| Parameter | Specification Range | Note/Standard |

| Nominal Pressure | 1.0 – 1.6MPa | ≈ PN10 – PN16 |

| Nominal Size (DN) | DN50 – DN350 | Common range for sewage discharge lines. |

| Applicable Temperature | 0°C – 80°C | Standard temperature range for municipal wastewater. |

| Applicable Media | Water, Weakly Corrosive Fluids, High-Viscosity Sewage & Suspended Solids | Specifically designed for dirty water. |

| Connection Standard | Flanged (GB/T 17241.6, GB/T 9113) | Robust connection standard. |

| Testing Standard | GB/T 13927, API598 | Tested for sealing and pressure integrity. |

🔩 Main Parts Material

| Component Name | Material Options | Key Function |

| Body, Bonnet | Ductile Iron (QT), Cast Steel | Provides strong, robust structure. |

| Ball (Disc) | Carbon Steel Core Encapsulated in Rubber (Rubber-Coated Ball) | The core sealing element; the rubber coating ensures a superior seal and minimizes wear. |

| Ball Guide/Slideway | Ductile Iron, Cast Steel (Integral with Body) | Guides the ball’s movement. |

⭐ Key Design and Performance Advantages

1. Anti-Clogging & Solids Handling

Rolling Ball Mechanism: The valve uses a rubber-coated rolling ball as its disc. Under media pressure, the ball rolls along an integral slideway within the body to open the valve.

Suitable for Sewage: This unique rolling action, combined with the smooth rubber surface, makes the valve self-cleaning and highly suitable for high-viscosity industrial and domestic sewage containing suspended solids, preventing the clogging common with general-purpose check valves.

2. Superior Hydraulics and System Protection

Full-Channel Structure: The valve body features a full water flow passage with no internal guides or hinges obstructing the flow path.

Low Resistance: Provides large flow capacity and low resistance, with head loss up to 50% less than conventional swing check valves.

Silent Closure: The cushioned closing action of the rubber ball ensures silent closing and does not produce water hammer, protecting pumps and pipelines.

3. Installation Versatility

Flexible Orientation: Can be installed in both horizontal and vertical pipelines, offering maximum flexibility for pump station design.

🏭 Ideal Application

This valve is the dedicated check valve for pressure drainage and sewage pump discharge systems in:

Wastewater Treatment Plants

Industrial Sewage Networks

Municipal Drainage and Pumping Stations

The rubber-coated rolling ball is the perfect sealing element for dirty water applications, ensuring long life and reliable sealing performance.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.