Water shut-off valves are essential components in residential, commercial, and industrial plumbing systems. Their main purpose is to control, isolate, or stop the flow of water during maintenance, repair, emergencies, or equipment replacement.

Because different applications require different types of valves, understanding each type is important for correct selection and long-term reliability.

This guide explains the most common types of water shut-off valves, their features, advantages, and best applications.

Table of Contents

Toggle1. Ball Valve

Best for: Main water lines, high-pressure systems, full-bore flow

A ball valve uses a spherical ball with a hole through the center.

Turning the handle 90 degrees opens or closes the valve completely.

Features:

Quarter-turn operation

Full port (no flow reduction)

Very reliable and leak-proof

Long service life

Applications:

Main residential shut-off valve

Commercial and industrial water systems

Irrigation, HVAC, well systems

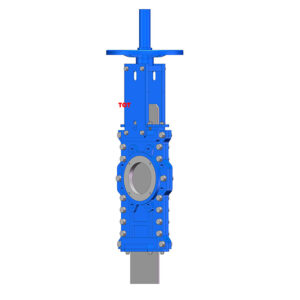

2. Gate Valve

Best for: Low-flow resistance and infrequent operation

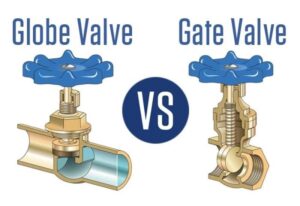

A gate valve uses a rising or non-rising metal gate that moves up and down.

Features:

Designed for fully open or fully closed use—not throttling

Smooth, low-resistance flow

Older homes often use gate valves

Applications:

Water mains

Outdoor water supply lines

Underground systems

Gate valves are reliable but prone to internal corrosion if not operated regularly.

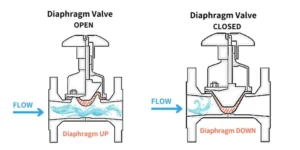

3. Globe Valve

Best for: Throttling and flow regulation

A globe valve uses a movable plug/disc and a stationary ring seat.

Features:

Precise flow control

Higher pressure drop than ball or gate valves

Strong sealing ability

Applications:

Water heaters

Commercial plumbing

Systems requiring flow adjustment

4. Angle Stop Valve

Best for: Under-sink and toilet supply connections

Angle stop valves (angle valves) are compact shut-off valves installed at fixtures.

Features:

90-degree bend

Control water to individual fixtures

Usually compression, threaded, or push-fit types

Applications:

Toilets

Faucets

Under-counter water appliances

5. Straight Stop Valve

Best for: Inline fixture shut-off

Similar to angle stops but with straight-through flow.

Applications:

When plumbing enters directly in-line with the fixture

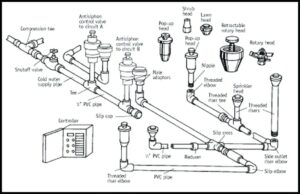

6. Compression Shut-Off Valve

Best for: Quick installation on copper or CPVC pipe

Installed using a compression nut and ferrule—no soldering required.

Features:

Easy to install

Leak-proof with proper tightening

Applications:

Sinks

Toilets

Small appliances

7. Push-Fit (Push-to-Connect) Valve

Best for: DIY installations and emergency repairs

Brands like SharkBite use push-fit connections.

Features:

No tools or soldering

Works with PEX, copper, and CPVC

Ideal for quick fixes

8. Stop-and-Waste Valve

Best for: Outdoor irrigation and winterizing systems

Allows draining water from the line when closed.

Features:

Prevents freezing damage

Used in yards, gardens, and seasonal buildings

9. Pressure Reducing Valve (PRV)

Best for: High-pressure water systems

Although not a traditional “shut-off” valve, PRVs regulate high inlet pressure and protect plumbing fixtures.

Features:

Adjustable pressure

Installed after the main meter

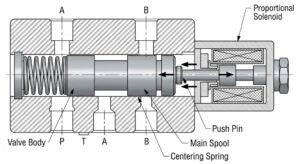

10. Solenoid Shut-Off Valve

Best for: Automatic leakage protection and smart water systems

Electrically controlled valve that closes automatically.

Features:

Used in smart home water leak systems

Remote or sensor-based shut-off

Applications:

Water leak detectors

HVAC systems

Commercial machinery

11. Automatic Excess Flow Shut-Off Valve

Best for: Emergency protection

Designed to close automatically when it detects abnormally high flow, such as from a burst pipe.

12. Multi-Turn vs Quarter-Turn Valves

| Valve Type | Operation | Example |

|---|---|---|

| Quarter-turn | Fast 90° turn | Ball valve, angle stop |

| Multi-turn | Several rotations | Gate valve, globe valve |

Quarter-turn valves are more modern and reliable, while multi-turn valves allow finer control but wear out faster.

How to Choose the Right Water Shut-Off Valve

Consider these factors:

Pipe size and material (PEX, copper, CPVC, steel)

Pressure and temperature levels

Need for manual vs automatic shut-off

Space restrictions

Flow requirements (full port vs reduced port)

Maintenance accessibility

Conclusion

Water shut-off valves range from simple under-sink stop valves to highly engineered solenoid and PRV systems. Selecting the right type ensures safety, reliable operation, and long-term performance in any plumbing system.