A Schrader valve is a type of pneumatic valve commonly used to inflate and deflate tires, air conditioning systems, and other pressurized equipment. Invented by August Schrader in 1891, it features a spring-loaded valve core inside a threaded metal stem that allows air to flow in while preventing it from escaping—making it the most widely used valve type in the world.

You’ll find Schrader valves on car tires, motorcycle tires, most mountain bike tires, air conditioning units, refrigeration systems, and countless pneumatic applications. In this guide, we’ll explain how Schrader valves work, compare them to Presta valves, and help you understand when to use each type.

Table of Contents

ToggleWhat Does a Schrader Valve Do?

The purpose of a Schrader valve is to provide a simple, reliable way to:

- Add air/gas to a pressurized system

- Release air/gas when needed

- Maintain pressure by automatically sealing when not in use

- Allow pressure measurement with gauges

The genius of the Schrader design is its automatic sealing mechanism—the valve stays closed until intentionally depressed, keeping air locked inside without any manual intervention.

How Does a Schrader Valve Work?

Understanding how Schrader valves work starts with their internal mechanism.

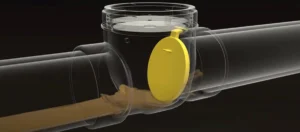

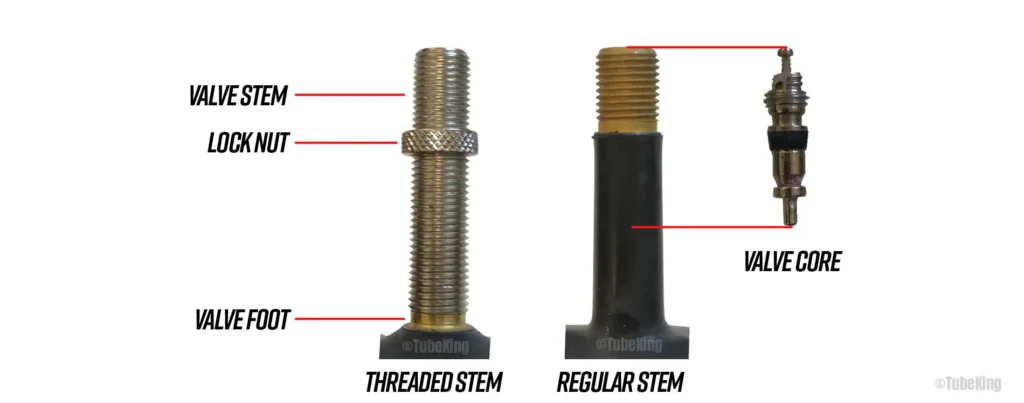

Valve Components

Key Components

| Component | Function |

|---|---|

| Valve cap | Protects valve core from dirt and debris |

| Valve core pin | When depressed, opens the valve |

| Spring | Keeps valve closed when not in use |

| Rubber seal | Creates airtight seal against the seat |

| Threaded stem | Allows secure attachment to rim or system |

How It Works

To inflate (add air):

- Air pump nozzle connects to valve

- Pump pressure pushes down the valve core pin

- Air flows past the seal into the tire/system

- When pump is removed, spring pushes seal closed

To deflate (release air):

- Press the center pin with a tool or fingernail

- Spring compresses, seal opens

- Air escapes until pin is released

- Spring returns seal to closed position

At rest: The spring constantly pushes the rubber seal against its seat, maintaining an airtight closure that holds pressure indefinitely (when properly functioning).

Schrader Valve Specifications

Schrader Valve Thread Size

The Schrader valve thread size is standardized for compatibility:

| Specification | Measurement |

|---|---|

| External thread diameter | 0.305″ (7.7mm) |

| Thread pitch | 32 TPI (threads per inch) |

| Thread standard | 0.302-32 UNEF |

| Valve core thread | M5 x 0.5mm |

| Stem diameter | 8mm (0.315″) |

Schrader Valve Dimensions

| Dimension | Standard Size |

|---|---|

| Overall stem length | Varies (20mm-60mm+ depending on application) |

| Rim hole diameter required | 8.5mm (0.335″) |

| Valve cap thread | Matches external stem thread |

The standardized Schrader thread dimensions ensure that any Schrader-compatible pump, gauge, or accessory works with any Schrader valve—whether on a bicycle, car, or air conditioning system.

What Is a Schrader Valve Used For?

Schrader valves are incredibly versatile. Here are the most common applications:

Automotive Tires

The most familiar use—virtually every car, truck, motorcycle, and ATV uses Schrader valves. Benefits include:

- Easy inflation at any gas station

- Durable enough for high speeds and temperatures

- Universal pump compatibility

Bicycle Tires

What is a Schrader valve on a bike? Many bicycles, especially mountain bikes, BMX bikes, and casual/commuter bikes, use Schrader valves because:

- Compatible with gas station air pumps

- More durable and harder to damage

- Easier for beginners to use

- No adapter needed for standard pumps

Air Conditioning and Refrigeration

What is a Schrader valve for AC? In HVAC systems, AC Schrader valves serve critical functions:

- Charging ports: Allow technicians to add refrigerant

- Service access: Enable pressure measurement and diagnostics

- Evacuation points: Used when recovering refrigerant

The Schrader valve in air conditioning systems is typically brass or stainless steel to handle refrigerant chemicals and pressure cycles.

Other Applications

- Pneumatic tools and equipment

- Suspension systems (air shocks, forks)

- Inflatable boats and recreational equipment

- Industrial compressed air systems

- Pressure testing equipment

- Football, basketball, and sports balls

Presta vs Schrader: Complete Comparison

One of the most common questions is the difference between Presta valve vs Schrader valve. Here’s everything you need to know.

What Is a Presta Valve?

A Presta valve (also called Sclaverand valve or French valve) is a narrower, lighter valve type primarily used on road bikes and high-performance bicycles. Unlike Schrader valves, Presta valves:

- Have no internal spring

- Use a manually operated lock nut

- Are narrower (6mm vs 8mm diameter)

- Require a smaller rim hole

Schrader Valve vs Presta Valve Comparison

| Feature | Schrader Valve | Presta Valve |

|---|---|---|

| Diameter | 8mm | 6mm |

| Rim hole size | 8.5mm | 6.5mm |

| Internal spring | Yes (automatic seal) | No (manual lock nut) |

| Operation | Push to inflate/deflate | Unscrew nut, then push |

| Durability | More robust | More delicate |

| Weight | Heavier | Lighter |

| Universal pump compatibility | Yes | Needs Presta-compatible pump |

| Gas station compatible | Yes | No (needs adapter) |

| Maximum pressure | ~65 PSI typical (higher with special cores) | 120+ PSI easily |

| Common on | Cars, MTB, casual bikes | Road bikes, high-end MTB |

Presta vs Schrader: Which Is Better?

Choose Schrader valves when:

- You want universal pump compatibility

- Durability matters more than weight

- You ride casually or on mountain bikes

- You want to use gas station air pumps

Choose Presta valves when:

- You need high pressure (100+ PSI)

- Weight savings matter (road racing)

- Your rims are narrow (road bike wheels)

- You have a Presta-compatible pump

Bike Valve Types Summary

| Valve Type | Best For | Rim Hole | Pressure Range |

|---|---|---|---|

| Schrader | MTB, casual, kids bikes | 8.5mm | Up to ~65 PSI standard |

| Presta | Road bikes, racing | 6.5mm | Up to 120+ PSI |

| Dunlop/Woods | Some European/Asian bikes | 8.5mm | Medium pressure |

Schrader Valve Adapters

Sometimes you need to adapt between valve types or connect accessories. Here are common adapter scenarios:

Presta to Schrader Valve Adapter

A Presta valve adapter (also called Presta to Schrader valve converter) screws onto a Presta valve stem, allowing you to:

- Use a standard Schrader pump on Presta valves

- Inflate Presta tubes at gas stations

- Use Schrader-only air compressors

How to use: Simply screw the small brass adapter onto the Presta valve’s threaded tip after opening the lock nut.

Schrader Valve Adapter Types

| Adapter Type | Purpose |

|---|---|

| Presta to Schrader | Use Schrader pumps on Presta valves |

| Schrader valve stem extender | Reach valves on deep-dish wheels |

| Schrader to air chuck | Connect to compressor or inflation systems |

| Schrader core removal tool | Remove/install valve cores |

Schrader Valve for Air Conditioning

Schrader valves in AC and refrigeration systems deserve special attention because they’re critical service components.

What Is a Schrader Valve on AC?

In air conditioning systems, AC Schrader valves (sometimes called service valves or access valves) are located on:

- High-pressure (discharge) line

- Low-pressure (suction) line

They allow HVAC technicians to:

- Measure system pressures

- Add or recover refrigerant

- Connect diagnostic equipment

- Perform vacuum evacuation

Schrader Valve Refrigeration Specifications

| Specification | Typical Value |

|---|---|

| Material | Brass or stainless steel |

| Pressure rating | Up to 500+ PSI |

| Temperature range | -40°F to 250°F |

| Connection | 1/4″ SAE flare (most common) |

Common AC Schrader Valve Issues

| Problem | Symptom | Solution |

|---|---|---|

| Leaking core | Slow refrigerant loss | Replace valve core |

| Damaged cap seal | Minor leaks | Replace cap with quality seal |

| Corroded threads | Difficult connections | Clean or replace valve |

| Stuck core | Won’t depress | Replace valve core |

Important: AC service should only be performed by certified technicians due to environmental regulations and safety concerns with refrigerants.

How to Inflate a Schrader Valve

On Bike or Car Tires

- Remove valve cap: Unscrew and set aside

- Check valve: Briefly press center pin—you should hear air escape

- Attach pump: Press pump head firmly onto valve

- Lock pump (if applicable): Flip lever to secure connection

- Inflate: Pump to desired pressure

- Remove pump: Release lever, pull straight off

- Replace cap: Screw cap back on finger-tight

Tips for Best Results

- Always replace valve caps—they keep dirt out of the valve core

- Press pump head straight on, not at an angle

- Check pressure with a reliable gauge

- Don’t overtighten caps (finger-tight is sufficient)

Schrader Valve Maintenance

Common Problems and Solutions

| Issue | Cause | Fix |

|---|---|---|

| Slow air leak | Damaged valve core | Replace core ($1-2) |

| Won’t hold air | Debris in valve | Clean or replace core |

| Hard to inflate | Sticky core | Lubricate or replace |

| Valve stem damage | Impact or corrosion | Replace entire valve stem |

Replacing a Schrader Valve Core

You’ll need a valve core removal tool (inexpensive and widely available):

- Deflate tire/system completely

- Insert tool into valve, engage threads

- Turn counterclockwise to remove core

- Inspect core for damage/debris

- Install new core, turn clockwise until snug

- Reinflate and check for leaks

Schrader Valve vs Standard Valve

You might wonder: is a Schrader valve the same as a standard valve? In most contexts, yes:

- “Standard valve” typically refers to Schrader valves

- “American valve” is another name for Schrader

- “Car valve” also means Schrader

The Schrader design has become so universal that it’s considered the standard for automotive, recreational, and many industrial applications.

Conclusion

The Schrader valve is a brilliantly simple invention that’s been reliably holding air for over 130 years. Its spring-loaded, self-sealing design works equally well on bicycle tires, car wheels, air conditioning systems, and countless other applications.

Key takeaways:

- Schrader valves use a spring-loaded core that automatically seals when not in use

- Standard thread size is 0.302-32 UNEF with an 8mm stem diameter

- They’re more durable and universally compatible than Presta valves

- Presta valves are better for high-pressure road bike applications

- AC Schrader valves allow refrigerant charging and system diagnostics

- Adapters are available to convert between Presta and Schrader

Whether you’re inflating bike tires, checking car tire pressure, or servicing an AC system, understanding Schrader valves helps you maintain your equipment properly and choose the right accessories.

Have questions about valves for your specific application? Contact our team for expert guidance on valve selection and compatibility.