A hydraulic pressure relief valve is a pressure-controlled valve that limits the maximum pressure in a hydraulic system by diverting excess flow back to the tank when pressure exceeds a preset limit. Unlike relief valves in water or steam systems that discharge to atmosphere, hydraulic relief valves route high-pressure oil back to the reservoir—protecting pumps, cylinders, hoses, and other components from catastrophic over-pressure failures.

In hydraulic systems, relief valves serve a dual role: they’re both a safety device preventing equipment damage and a control element enabling pressure-compensated operation. A properly set relief valve is the difference between a hydraulic system that runs reliably for decades and one that suffers frequent hose bursts, seal failures, and expensive downtime.

Whether you’re operating heavy machinery, maintaining industrial equipment, or designing hydraulic circuits, understanding how hydraulic relief valves work is essential for system safety and performance.

Table of Contents

ToggleWhat Makes Hydraulic Relief Valves Different?

Before diving into specifics, let’s understand what makes hydraulic applications unique:

Key Differences from Other Relief Valves

| Feature | Hydraulic Relief Valve | Water/Steam Relief Valve |

|---|---|---|

| Discharge destination | Returns to tank (closed circuit) | Vents to atmosphere |

| Operating pressure | 500-10,000+ PSI | 50-300 PSI typical |

| Fluid type | Hydraulic oil (incompressible) | Water, steam (various) |

| Response time | Milliseconds (critical) | Seconds acceptable |

| Precision required | ±50 PSI typical | ±10% acceptable |

| Control function | Often used for circuit control | Purely safety device |

| Cycling frequency | May operate continuously | Rarely opens |

Why Hydraulic Systems Need Special Relief Valves

Incompressible fluid challenges:

- Oil doesn’t compress like air or steam

- Pressure spikes happen instantly

- No “cushion” to absorb surges

- Requires immediate response

High pressure demands:

- Mobile hydraulics: 2,500-5,000 PSI

- Industrial systems: 1,000-3,000 PSI

- Servo systems: up to 10,000 PSI

- Even small leaks are dangerous at these pressures

Closed circuit requirements:

- Can’t vent oil to atmosphere (environmental, cost)

- Must return to tank cleanly

- Heat generation must be managed

- Continuous cycling often required

Function of Relief Valve in Hydraulic System

The function of relief valve in hydraulic system goes beyond simple over-pressure protection. Let’s explore the multiple roles these valves play.

Primary Functions

1. System Protection (Safety)

Prevents catastrophic failures:

- Limits maximum pressure to safe levels

- Protects pumps from over-pressure damage

- Prevents hose and fitting ruptures

- Guards against cylinder rod buckling

- Shields seals from excessive pressure

Without relief valve:

Blocked cylinder → Pressure rises → Hose bursts

→ Seal fails

→ Pump destroys itself

With relief valve:

Blocked cylinder → Pressure rises → Relief opens →

Pressure limited → System protected → Operator alerted

2. Overload Protection

Acts as mechanical circuit breaker:

- When load exceeds design, relief opens

- Prevents damage to work equipment

- Protects expensive tooling

- Allows operator intervention

Example: Excavator bucket hits rock

- Relief opens immediately

- Pressure limited

- Machine stops pushing

- No damage to boom, cylinder, or hydraulics

3. Pressure Control

Enables sophisticated control:

- Sets maximum system pressure

- Creates secondary pressure circuits

- Enables pressure-compensated pump operation

- Allows sequencing of operations

4. Heat Limiting (Indirect)

Prevents thermal damage:

- Opening relief valve generates heat

- But limits overall system heating

- Prevents sustained high-pressure operation

- Protects fluid from thermal breakdown

How Does a Hydraulic Pressure Relief Valve Work?

Understanding the hydraulic relief valve working principle reveals why proper selection and adjustment are critical.

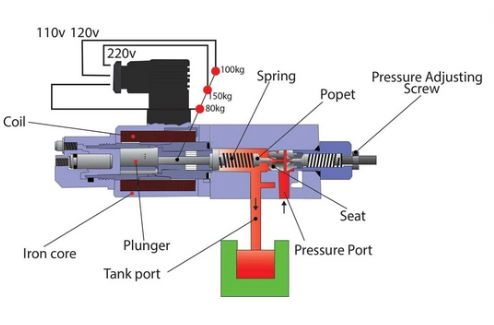

Basic Direct-Acting Relief Valve

HYDRAULIC RELIEF VALVE OPERATION

NORMAL OPERATION (Below Set Pressure)

Adjustment Screw

│

┌────┴────┐

│ Spring │

│ ║║║║║║ │ ← Holding poppet closed

│ ║║║║║║ │

└────┬────┘

│

┌────┴────┐

│ Poppet │

═════█████████═════ ← Sealed

│ │

From Pump To Tank (blocked)

System Pressure: 1200 PSI

Spring Setting: 1500 PSI

Relief: CLOSED

OVER-PRESSURE (Relief Opening)

Adjustment Screw

│

┌────┴────┐

│ Spring │

│ ╱╲╱╲ │ ← Spring compressed

│ ╱ ╲ │

└────┬────┘

│

┌────┴────┐

│ Poppet │ ← Lifted off seat

═════╪═════════╪═════

│ ▼ │

From Pump To Tank ← Oil flowing

System Pressure: 1550 PSI

Spring Setting: 1500 PSI

Relief: OPEN - Dumping to tank

Step-by-Step Operation

Phase 1: Normal Operation

- Pump delivers flow to system

- Pressure determined by load resistance

- Spring holds poppet firmly closed

- All pump flow goes to actuators

- Minimal flow through relief valve

Phase 2: Approaching Set Pressure

- Load increases or flow blocked

- System pressure rises

- Pressure pushes against poppet

- Spring resists, keeping valve closed

- Pressure continues building

Phase 3: Relief Opens (Cracking Pressure)

- Pressure overcomes spring force

- Poppet begins to lift

- Small amount of oil flows to tank

- Pressure stabilizes at set point

- Relief modulates to maintain pressure

Phase 4: Full Relief (Maximum Flow)

- All pump flow diverted to tank

- Actuators stall (no flow to them)

- Maximum heat generation

- Pressure maintained at relief setting

- System “dead-headed”

Phase 5: Return to Normal

- Load reduces or flow path opens

- Pressure drops below set point

- Spring closes poppet

- Flow returns to actuators

- Normal operation resumes

Types of Hydraulic Relief Valves

Different hydraulic applications require different relief valve types. Selecting the right type is crucial for performance and longevity.

1. Direct-Acting Relief Valve

Construction:

- Spring directly opposes system pressure

- Poppet or spool lifts against spring

- Simple, compact design

Adjustment

│

┌───┴───┐

│Spring │

│ ║║║║║ │

└───┬───┘

┌───┴───┐

│Poppet │

╪═══════╪

P T

Characteristics:

- Pressure override: 10-20% above set pressure at full flow

- Response time: Very fast (milliseconds)

- Accuracy: ±100-200 PSI typical

- Flow capacity: Up to 60 GPM typical

Best for:

- Simple circuits

- Low to medium flow

- Applications where override is acceptable

- Compact installations

Limitations:

- Pressure rises with flow (poor regulation)

- Not suitable for precise pressure control

- Can be noisy at high flows

2. Pilot-Operated Relief Valve

Construction:

- Small pilot valve controls large main poppet

- Uses system pressure to help close main valve

- Two-stage operation

Pilot Adjustment

│

┌────┴────┐

│ Pilot │ ← Small direct-acting valve

│ Spring │

└────┬────┘

│

┌────┴────┐

│ Pilot │

│ Line │ ← Connects to main poppet

└────┬────┘

│

┌─────────┴──────────┐

│ Main Poppet │ ← Large, pressure-balanced

│ (Spring-loaded) │

╪════════════════════╪

P T

Characteristics:

- Pressure override: 3-5% above set pressure

- Response time: Slightly slower than direct

- Accuracy: ±10-50 PSI

- Flow capacity: 500+ GPM possible

Best for:

- High flow applications

- Precise pressure control needed

- Large industrial systems

- Servo/proportional control systems

Advantages:

- Excellent pressure regulation

- Handles large flows efficiently

- Lower power consumption

- Quieter operation

Limitations:

- More complex (more failure points)

- Requires filtered oil (pilot orifice small)

- More expensive

- Slower response than direct acting

3. Unloading Relief Valve

Function:

- Diverts pump flow to tank at low pressure

- Reduces power consumption during idle

- Accumulator charging applications

Operation:

- When pressure reaches set point, valve shifts

- Pump flow goes to tank at ~100 PSI

- Huge energy savings versus full-pressure relief

- Resets when pressure drops

Applications:

- Systems with accumulators

- Idle periods in cycle

- Energy-efficient designs

4. Counterbalance Valve

Function:

- Maintains back pressure on actuator

- Prevents load from running away

- Controls lowering speed

Applications:

- Vertical cylinders holding loads

- Crane booms and lifts

- Press brake ram control

5. Sequence Valve

Function:

- Similar to relief but in series with circuit

- Requires pressure in one circuit before allowing flow to next

- Creates operational sequences

Applications:

- Clamping before drilling

- Multi-cylinder sequencing

- Automatic operation sequences

Hydraulic Relief Valve Adjustment and Setting

Proper adjustment of hydraulic relief valves is critical for system protection and performance.

How to Adjust a Hydraulic Relief Valve

Required tools:

- Hydraulic pressure gauge (accurate, appropriate range)

- Wrench or hex key (for adjustment screw)

- System documentation (know required pressure)

Procedure:

1. Install Accurate Gauge

- Connect to gauge port near relief valve

- Ensure gauge range exceeds expected pressure

- Verify gauge is recently calibrated

2. Run System to Operating Temperature

- Cold oil behaves differently than hot

- Run for 15-20 minutes minimum

- Check oil temperature (120-140°F typical)

3. Create Load Condition

- Stall cylinder against hard stop, OR

- Use load-sensing method, OR

- Block flow with needle valve

4. Adjust Relief Setting

- Loosen locknut on adjustment screw

- Turn screw to adjust (usually clockwise = increase)

- Make small adjustments (1/4 turn at a time)

- Allow pressure to stabilize between adjustments

5. Verify Setting

- System pressure should stabilize at desired set point

- Check pressure doesn’t continue rising

- Test multiple times for consistency

- Lock adjustment when satisfied

6. Final Checks

- Tighten locknut securely

- Remove gauge (or leave if permanent)

- Document setting in maintenance log

- Label valve with set pressure

Typical Pressure Settings

| Application | Typical Relief Setting |

|---|---|

| Mobile equipment (general) | 2,500-3,000 PSI |

| Excavators, loaders | 3,000-3,500 PSI |

| Industrial presses | 1,500-2,500 PSI |

| Machine tool hydraulics | 1,000-1,500 PSI |

| Low-pressure circuits | 500-800 PSI |

| High-pressure intensifiers | 5,000-10,000 PSI |

Setting Best Practices

General rule: Set relief 10-25% above maximum normal operating pressure

Example:

- Normal operating pressure: 1,200 PSI

- Relief setting: 1,500 PSI (25% margin)

- Provides safety margin without nuisance opening

Avoid:

- Setting too close to operating pressure (constant cycling)

- Setting too high (inadequate protection)

- Adjusting “by feel” without gauge

- Cranking to maximum “just to be safe”

Hydraulic Relief Valve Sizing and Selection

Proper sizing ensures the relief valve can handle required flow without excessive pressure rise.

Key Sizing Parameters

1. Maximum Flow Rate

Question: What is the pump’s maximum flow?

Why it matters: Relief valve must handle full pump flow when system is blocked

Example:

- Pump: 20 GPM at 1,800 RPM

- Relief valve must handle 20+ GPM

2. System Pressure

Question: What is your operating pressure and desired relief setting?

Why it matters: Determines spring range and valve body rating

3. Pressure Override

Question: How much pressure rise above set point is acceptable?

Direct-acting: 10-20% override typical Pilot-operated: 3-5% override

Example:

- Set pressure: 1,500 PSI

- Direct-acting override: 1,650-1,800 PSI at full flow

- Pilot-operated override: 1,545-1,575 PSI at full flow

4. Fluid Characteristics

- Viscosity (ISO VG rating)

- Temperature range

- Cleanliness (filtration level)

Selection Process

Step 1: Determine required flow capacity (pump GPM)

Step 2: Choose valve type

- Direct-acting: Flow < 40 GPM, override acceptable

- Pilot-operated: Flow > 40 GPM, precise control needed

Step 3: Select pressure range

- Ensure set pressure within valve’s adjustable range

- Consider system spikes (may need higher-rated body)

Step 4: Choose connection type

- Inline (threaded ports)

- Manifold mount (cartridge)

- Subplate mount

Step 5: Verify specifications

- Cracking pressure

- Full flow pressure override

- Maximum rated pressure (body)

- Port sizes match system

Common Hydraulic Relief Valve Problems

1. Relief Valve Opening Too Soon (Pressure Too Low)

Symptoms:

- System won’t reach full pressure

- Cylinders move slowly or won’t move

- Pump makes noise continuously

- System overheating

Causes:

- Relief set too low

- Weak or broken spring

- Contamination holding valve open

- Wrong spring installed

Diagnosis:

- Install gauge, check actual pressure

- Compare to expected pressure

- Listen for flow noise at relief valve

Solutions:

- Re-adjust to proper setting

- Replace spring

- Clean valve thoroughly

- Verify correct spring for pressure range

2. Relief Valve Not Opening (Pressure Too High)

Symptoms:

- System pressure exceeds design limits

- Hoses bulging or bursting

- Pump making severe noise

- Extreme heat generation

Causes:

- Relief set too high

- Adjustment screw bottomed out

- Spool/poppet stuck closed

- Contamination blocking valve

Diagnosis:

- Check gauge reading

- Verify relief adjustment within range

- Attempt manual override (if equipped)

Solutions:

- IMMEDIATE: Shut down system (safety hazard!)

- Reduce relief setting to proper pressure

- Disassemble and clean valve

- Replace if damaged

3. Chattering/Oscillation

Symptoms:

- Rapid vibration/noise from valve

- Pressure fluctuations

- Potential component damage

Causes:

- Air in system

- Relief valve too large for flow

- Poor inlet pressure (cavitation)

- Resonance with system frequency

Solutions:

- Bleed air from system

- Resize valve to actual flow

- Add inlet restriction or accumulator

- Change relief valve type

4. Continuous Flow Through Relief (System Dead-Headed)

Symptoms:

- System won’t move actuators

- All flow going to tank through relief

- Extreme heat generation

- Wasted energy

Causes:

- Actuator control valve closed

- Blocked line downstream

- Actuator mechanically stalled

- System overloaded

Solutions:

- Check directional control valves

- Inspect for blocked lines

- Reduce load if overloaded

- Verify proper system design

5. Relief Valve Leaking Externally

Symptoms:

- Oil seeping from adjustment cap

- Oil leaking from ports

- Puddle under valve

Causes:

- Damaged O-rings

- Cracked body

- Loose fittings

- Excessive pressure spikes

Solutions:

- Replace O-rings and seals

- Inspect body for cracks (replace if damaged)

- Tighten fittings to proper torque

- Add shock damping if spikes present

Relief Valve in Hydraulic System: Circuit Applications

Basic Protection Circuit

SIMPLE HYDRAULIC CIRCUIT WITH RELIEF

┌─────────┐

│ Motor │

│ M │

└────┬────┘

│

┌────┴────┐

│ Pump │

│ P │

└────┬────┘

│

├──────► [Directional Valve] ──► [Cylinder]

│

├──────► [Relief Valve] ──┐

│ (1500 PSI) │

│ │

└─────────────────────────┴──► [Tank]

Function: Limits maximum system pressure

Dual Pressure Circuit

HIGH/LOW PRESSURE CIRCUIT

[Pump] ──┬──► High Pressure Circuit

│ └─► [Relief 3000 PSI]

│

└──► Low Pressure Circuit

└─► [Relief 1000 PSI]

Function: Different pressures for different functions

Example: Fast extend (low P), slow force (high P)

Accumulator Circuit with Unloading

ACCUMULATOR WITH UNLOADING RELIEF

[Pump] ──┬──► [Accumulator]

│ │

│ └─► [Pressure Switch]

│ │

└──► [Unloading Valve] ──► [Tank]

Function:

- Charges accumulator to set pressure

- Unloads pump to tank at low pressure during standby

- Saves energy during idle periods

Maintenance and Inspection Schedule

Daily Checks (Operators)

- Visual inspection for leaks

- Listen for unusual noises

- Check pressure gauge readings

- Note any performance changes

Monthly Inspection (Maintenance)

- Verify no external leaks

- Check adjustment locknut tight

- Test pressure with calibrated gauge

- Document pressure readings

Quarterly Service

- Full pressure test under load

- Verify pressure holds steady

- Check for excessive override

- Inspect mounting and connections

Annual Overhaul

- Remove and disassemble valve

- Inspect all internal components:

- Spring (check for fatigue, corrosion)

- Poppet/spool (wear, scoring)

- Seat (damage, erosion)

- O-rings and seals (replace all)

- Clean all parts thoroughly

- Reassemble with new seals

- Bench test if possible

- Re-install and pressure test

- Document and tag

Replacement Indicators

Replace relief valve if:

- Excessive wear on poppet or seat

- Spring permanently compressed or broken

- Body cracked or corroded

- Cannot maintain stable pressure

- History of frequent problems

- Unknown service history

- Over 10 years old (preventive)

Troubleshooting Decision Tree

SYSTEM PRESSURE PROBLEM

Is pressure too HIGH?

│

├─ YES → Is relief valve adjusted correctly?

│ │

│ ├─ NO → Re-adjust to proper setting

│ │

│ └─ YES → Valve stuck closed?

│ └─ Clean/replace valve

│

└─ NO → Pressure too LOW?

│

└─ YES → Check relief valve setting

│

├─ Set too low → Re-adjust

│

├─ Valve leaking → Clean/replace

│

└─ Wrong spring → Install correct spring

Conclusion

Hydraulic pressure relief valves are critical safety and control components that protect expensive equipment while enabling sophisticated hydraulic circuit operation. Unlike relief valves in other applications, hydraulic relief valves must respond instantly to pressure spikes, handle incompressible fluids at extreme pressures, and return flow cleanly to the tank rather than venting to atmosphere.

Key takeaways:

- Hydraulic relief valves serve dual roles: safety protection and circuit control

- Direct-acting valves are simple but have significant pressure override

- Pilot-operated valves provide precise pressure control for demanding applications

- Proper setting is critical—typically 10-25% above normal operating pressure

- Regular testing and maintenance prevent catastrophic failures

- Relief valve opening is not a fault—it’s doing its job protecting the system

- Never disable, plug, or over-adjust a relief valve

Whether you’re operating a hydraulic excavator, maintaining industrial presses, or designing custom hydraulic circuits, understanding hydraulic relief valve function and operation ensures safe, efficient, and reliable hydraulic system performance.

Need hydraulic system assistance? Consult with qualified hydraulic technicians for relief valve selection, adjustment, and troubleshooting.