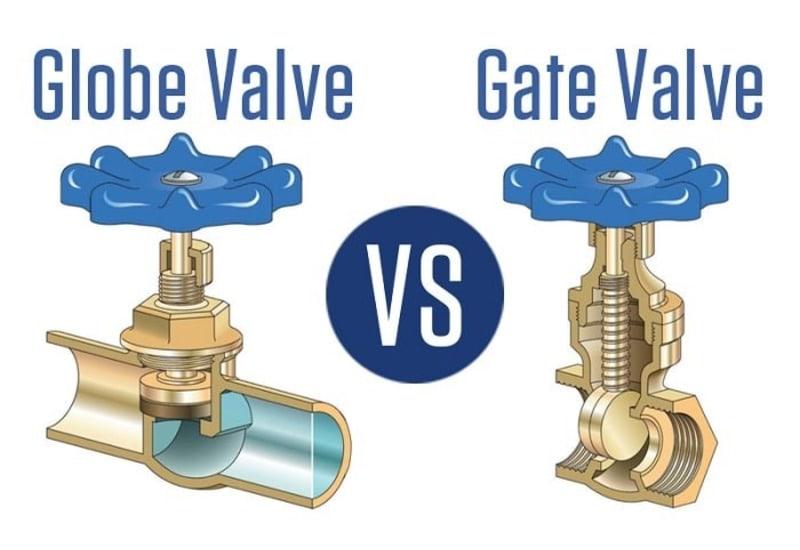

Gate valves and globe valves serve fundamentally different purposes: gate valves are designed for full on/off isolation with minimal pressure drop, while globe valves excel at flow regulation and throttling. Choosing the wrong type can lead to premature valve failure, energy waste, and operational problems. A gate valve forced to throttle will experience rapid erosion and failure, while a globe valve used for simple isolation is unnecessarily expensive and creates avoidable pressure loss.

This isn’t just a technical distinction—it’s a critical decision that affects system efficiency, maintenance costs, and equipment lifespan. Install a gate valve where you need flow control, and you’ll be replacing it within months. Use a globe valve for basic isolation, and you’re paying premium prices while wasting pump energy overcoming unnecessary pressure drop.

Executive Summary: The fundamental difference is their purpose: Gate valves are for isolation (on/off) and offer zero flow resistance, while Globe valves are designed for flow regulation (throttling). Never use a gate valve to throttle, or it will fail prematurely due to erosion.

In this comprehensive comparison, we’ll examine every aspect of gate valves versus globe valves to help you make the right choice for your specific application.

| Feature / Metric | Gate Valve | Globe Valve | Practical Impact on Selection |

| Primary Function | Isolation (Full On / Full Off) | Regulation / Throttling (Flow Control) | Gate Valve provides little control; Globe Valve is designed for modulation. |

| Flow Path | Straight-through and Unobstructed | Tortuous (S-shaped or Z-shaped) | Crucial for energy efficiency (see Pressure Drop). |

| Pressure Drop ($\Delta P$) | Very Low. Minimal resistance when fully open. | High. Resistance is inherent to the throttling design. | Globe Valve consumes significantly more energy over the long term. |

| Sealing Direction | Bi-directional (Can block flow from either side). | Strictly Uni-directional (Must be installed with flow arrow). | Wrong installation of Globe Valve causes poor sealing and chatter. |

| Throttling Use | Not Recommended / Forbidden. Causes severe seat erosion and leakage. | Excellent. Designed to withstand high differential pressure during partial opening. | Use the right tool for the job to avoid rapid failure. |

| Maintenance | Seat resurfacing is difficult; often requires full replacement. | Disc and seat can often be repaired or replaced in-line. | Globe Valve may offer better Life Cycle Cost (LCC) despite high initial cost. |

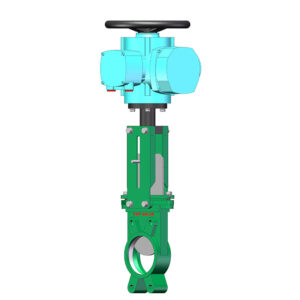

| Media Suitability | Clean fluids; Knife Gate variants for Slurries and Viscous Fluids. | Clean fluids (Water, Steam, Air) or where solids won’t accumulate in the seat pocket. | Gate Valve handles dirty media better due to self-cleaning gate action. |

Table of Contents

ToggleQuick Decision Guide: Which Valve Do You Need?

Before diving into details, here’s a quick reference:

Choose a Gate Valve If:

✅ You need simple on/off control (fully open or fully closed)

✅ Minimal pressure drop is critical

✅ The valve will be operated infrequently (isolation service)

✅ You want straight-through flow with no restrictions

✅ Lower cost is important

✅ Space constraints favor slim, compact design

Typical applications: Main water shutoffs, isolation valves, pipeline sectioning

Choose a Globe Valve If:

✅ You need flow regulation (throttling/modulation)

✅ The valve will be adjusted frequently

✅ Tight shutoff is essential

✅ You need automatic control capability

✅ Pressure reduction is beneficial

✅ Precise flow control matters

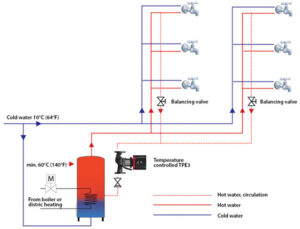

Typical applications: Steam control, cooling water regulation, fuel flow adjustment, HVAC balancing

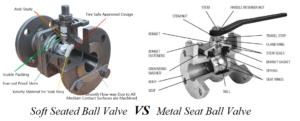

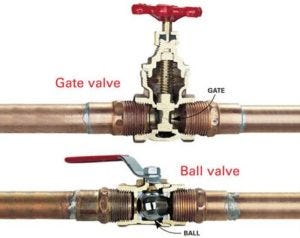

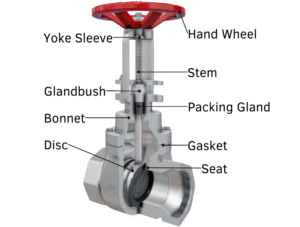

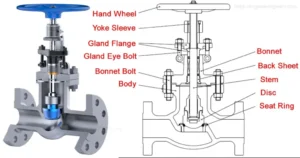

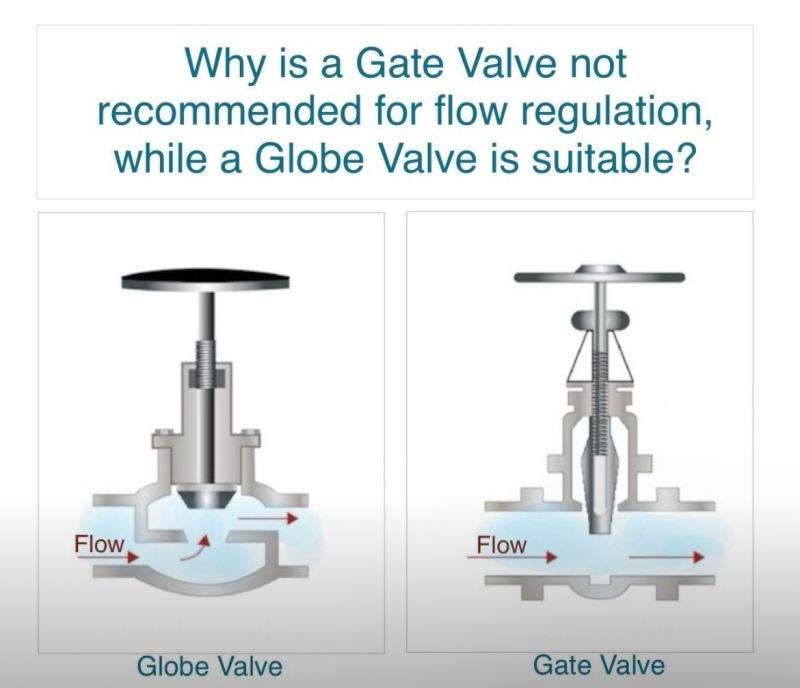

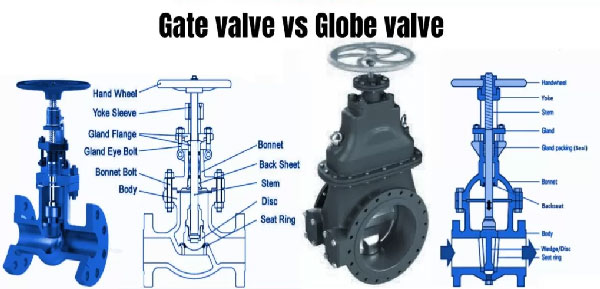

Visual Comparison: How to Tell Them Apart

External Appearance

Key Visual Identifiers

| Feature | Gate Valve | Globe Valve |

|---|---|---|

| Body shape | Rectangular, slim | Spherical, bulbous |

| Height | Moderate | Taller (more overhead needed) |

| Width | Narrow | Wider body |

| Inlet/outlet alignment | Straight line, same level | Same line, different levels |

| Overall size | Compact | Larger, heavier |

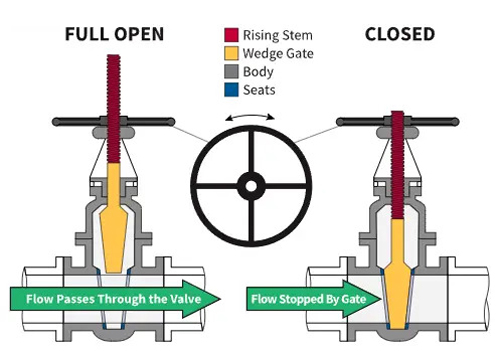

Flow Path: The Fundamental Difference

The flow path difference explains why these valves perform so differently.

Gate Valve: Straight-Through Flow

Characteristics:

- Flow continues in straight line

- No direction changes

- Gate slides completely out of flow path when open

- Minimal turbulence

- Pressure drop: 0.5-2 PSI typical when fully open

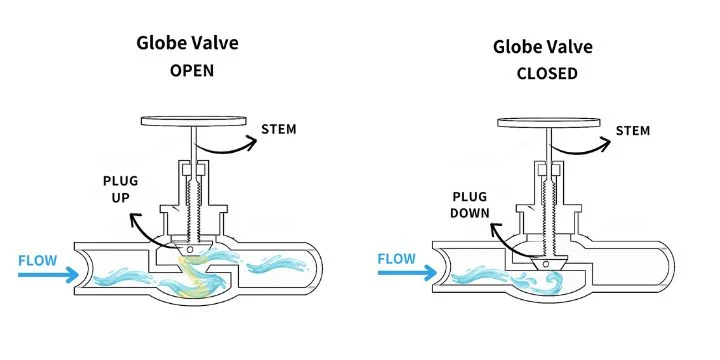

Globe Valve: Directional Change Flow

Characteristics:

- Flow enters, rises, changes direction

- S-shaped or Z-shaped path

- Disc always in flow path (even when fully open)

- Creates turbulence

- Pressure drop: 5-25 PSI typical when fully open

Complete Feature Comparison

Performance Characteristics

| Feature | Gate Valve | Globe Valve |

|---|---|---|

| Pressure drop (fully open) | Very low (0.5-2 PSI) | Moderate to high (5-25 PSI) |

| Flow capacity | 100% of pipe size | 60-80% of pipe size |

| Shutoff quality | Good (metal-to-metal or resilient) | Excellent (tight seal) |

| Throttling ability | ❌ Poor—causes damage | ✅ Excellent—designed for it |

| Response to adjustment | ❌ Nonlinear | ✅ Linear, predictable |

| Wear when throttling | ❌ Rapid erosion | ✅ Minimal wear |

| Noise & Vibration | High (Screaming/Chippering when throttled) | Low to Moderate (Designed for stable flow) |

Operational Characteristics

| Feature | Gate Valve | Globe Valve |

|---|---|---|

| Operation speed | Slow (multi-turn) | Slow (multi-turn) |

| Position indicator | Rising stem shows position | Rising stem shows position |

| Best operating positions | Fully open OR fully closed | Any position |

| Frequency of adjustment | Infrequent (isolation only) | Frequent (control service) |

| Control precision | Not applicable | High precision |

| Automation suitability | On/off only | Excellent for modulating control |

Physical Characteristics

| Feature | Gate Valve | Globe Valve |

|---|---|---|

| Body size | Compact, slim | Large, bulbous |

| Weight | Lighter | Heavier |

| Face-to-face length | Shorter | Longer |

| Installation height | Lower | Higher (more clearance needed) |

| Piping stress | Lower | Higher (heavier body) |

Economic Factors

| Feature | Gate Valve | Globe Valve |

|---|---|---|

| Initial cost | Lower (simple design) | Higher (complex design) |

| Energy cost | Lower (minimal pressure loss) | Higher (continuous pressure loss) |

| Maintenance cost | Lower (if used correctly) | Moderate (more components) |

| Lifespan in throttling | Short (rapid failure) | Long (designed for it) |

| Total cost of ownership | Lower for isolation | Lower for control |

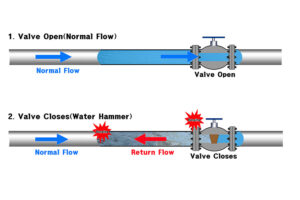

The Throttling Problem: Why Gate Valves Fail

This is the single most critical difference and the most common mistake. Imagine a high-pressure jet of water acting like a laser beam. In a partially open gate valve, the fluid accelerates to extreme velocities, literally ‘cutting’ a permanent groove into the metal wedge. This is wire-drawing, and once it starts, the valve is a total loss.

The Hidden Risk: Stem Packing and Leakage

Beyond flow control, there is a major difference in how these valves handle sealing at the stem.

Gate Valve Weakness: Because a gate valve requires the stem to travel a long distance to lift the wedge, it creates significant friction against the stem packing. If the valve is cycled frequently, the packing wears down quickly, leading to stem leaks.

Globe Valve Superiority: A globe valve has a much shorter stroke, meaning less wear on the seals. More importantly, for hazardous, toxic, or expensive media, globe valves can be fitted with a Bellows Seal. This provides a permanent, hermetic metal seal that guarantees zero-leakage to the atmosphere—an option rarely practical for standard gate valves.

Expert Verdict: If you are handling hazardous chemicals or high-pressure steam where any leak is a safety violation, the Globe Valve is the responsible choice.

What Happens When You Throttle a Gate Valve

Failure mechanisms:

- Wire drawing: High-velocity flow cuts across gate edge like a knife

- Erosion: Metal removed from gate and seat surfaces

- Vibration: Partially open gate chatters, accelerating wear

- Cavitation: Low pressure behind gate causes vapor bubbles that implode violently

- Noise: Can be deafening (>100 dB)

Timeline to failure:

- Continuous throttling: Weeks to months

- Intermittent throttling: Months to 1-2 years

- Proper use (full open/closed): 10-20+ years

Why Globe Valves Handle Throttling

Why globe valves succeed:

- Disc design: Contoured to guide flow smoothly

- Hardened materials: Seat area uses erosion-resistant materials

- Flow direction: Works with flow, not against it

- Seat replacement: Easy to replace worn seats

- Linear characteristic: Predictable flow vs. position

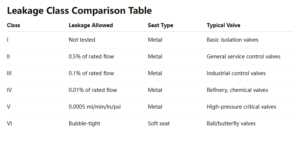

Material & Compliance Standards (E-A-T Signal)

To ensure system longevity, you must specify valves according to the correct industrial standards. This is where many generic articles fall short.

For Gate Valves (API 600 / 603): Typically specified for heavy-duty industrial isolation.

For Globe Valves (API 623): This is the modern standard for steel globe valves, focusing on sturdier stem designs and harder seat materials (like Stellite #6) to withstand the stresses of throttling.

Expert Tip: If your medium is steam, always specify a Globe Valve with a plug-type disc and Stellite hard-faced seats to prevent steam cutting.

Real-World Selection: Which One Do You Need?

Case A: Main Water Supply Isolation

Requirement: Low energy loss, infrequent operation.

Winner: Gate Valve. You don’t want a permanent pressure drop in your main line.

Case B: Steam Control for a Heat Exchanger

Requirement: Frequent adjustments to maintain temperature.

Winner: Globe Valve. The linear movement of the plug allows for predictable flow modulation.

Frequently Asked Questions

Can I use a gate valve if I only throttle occasionally?

No. Even occasional throttling damages gate valves. If there’s any possibility of throttling—even for emergencies—use a globe valve or install both types.

Why not just use globe valves everywhere?

Cost and efficiency. Globe valves are more expensive and create permanent pressure loss. Using them for simple isolation wastes money and energy.

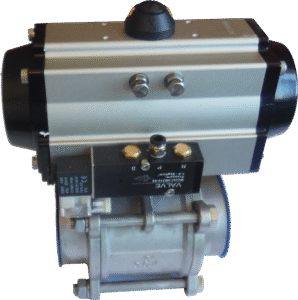

What about ball valves?

Ball valves offer quick on/off operation (quarter-turn) but should NOT be used for throttling either. They’re excellent for isolation but different from both gate and globe valves.

Can I convert a gate valve location to a globe valve?

Yes, but consider:

- Different face-to-face dimensions

- Higher pressure drop (may affect system)

- Pipe stress from heavier weight

- May need different supports

How do I tell which type is installed?

Visual inspection:

- Gate: Slim body, inline ports

- Globe: Bulbous body, stepped ports

- Check nameplate or body markings

Conclusion

Gate valves and globe valves are not interchangeable—they’re designed for fundamentally different purposes. Gate valves excel at isolation with minimal pressure drop, while globe valves are essential for flow control and throttling. Using the wrong type leads to premature failure, energy waste, and unnecessary maintenance costs.

Key decision factors:

| If you need… | Choose… |

|---|---|

| On/off isolation only | Gate valve |

| Flow control or throttling | Globe valve |

| Minimal pressure drop | Gate valve |

| Frequent adjustment | Globe valve |

| Lowest initial cost (for isolation) | Gate valve |

| Lowest total cost (for control) | Globe valve |

Quick Decision Flowchart: Gate Valve or Globe Valve?

Question 1: Is the primary need to regulate/modulate flow rate (Throttling)?

YES → Choose Globe Valve. (The design is optimized for partial opening.)

NO (Need Full On/Full Off Isolation only) → Go to Question 2.

Question 2: Is minimizing system pressure drop (ΔP) and energy consumption the top priority?

YES → Choose Gate Valve. (Provides clear, straight flow path.)

NO (Pressure drop is acceptable) → Go to Question 3.

Question 3: Is the medium highly viscous or does it contain abrasive solids (Slurries, heavy oil)?

YES → Choose Gate Valve (or specialized Knife Gate). (The straight path and shearing action handle solids better.)

NO (Clean fluid required) → Go to Question 4.

Question 4: Is the valve used in a system that requires frequent operation or quick shut-off?

YES → Choose Globe Valve. (Shorter stroke, faster operation than Gate Valve.)

NO (Infrequent operation, e.g., line isolation) → Choose Gate Valve.

The most critical rule: Never use gate valves for throttling—even occasionally. The cost of replacing failed gate valves far exceeds the initial savings. When in doubt, choose the globe valve for any application involving flow adjustment.

Understanding these differences ensures proper valve selection, optimal system performance, and minimized total cost of ownership over the equipment lifecycle.

Building a steam system? Get our pre-selected Valve Package specifically designed for Boiler Feedwater service.