A choke valve works by creating a deliberate restriction in the flow path, converting high pressure into controlled lower pressure through a precisely sized orifice—allowing oil and gas operators to regulate production flow rates, maintain optimal wellhead pressure, and protect downstream equipment from damage. Unlike standard valves that simply open or close, choke valves are specifically designed to handle the extreme pressures, erosive fluids, and precise flow control demands of oil and gas production.

In wellhead operations, production fluids emerge from thousands of feet underground at tremendous pressures—sometimes exceeding 10,000 PSI. A choke valve transforms this dangerous high-pressure flow into manageable, controlled pressure that downstream equipment can safely handle. Without proper choke valve operation, wells could flow uncontrollably, equipment could fail catastrophically, and production would be unsafe and inefficient.

This guide explains the fundamental working principles of choke valves, their role in wellhead systems, the different types and how they operate, and why they’re essential for safe, optimized oil and gas production.

Table of Contents

ToggleWhat Is a Choke Valve? Quick Overview

Before explaining how it works, let’s clarify what a choke valve is:

Choke Valve Definition

A choke valve is a pressure-control device used in oil and gas production to:

- Restrict flow through a precisely sized orifice

- Convert high upstream pressure to lower downstream pressure

- Control production flow rates

- Protect downstream equipment

- Optimize reservoir performance

Key Characteristics

CHOKE VALVE IN WELLHEAD

Underground Wellhead Downstream

Reservoir (Surface) Equipment

│ │ │

High Pressure CHOKE VALVE Controlled

10,000 PSI ↓↓↓ Lower Pressure

│ Restriction 2,000 PSI

└────────────────┴──────────────────┘

Pressure Control

Not to be confused with:

- ❌ Engine choke (carburetor air restriction)

- ❌ Standard flow control valves (general purpose)

- ❌ Globe valves (different design/purpose)

The Basic Working Principle

How Choke Valves Control Flow

A choke valve operates on a fundamental fluid dynamics principle: flow restriction causes pressure drop.

CHOKE VALVE WORKING PRINCIPLE

UPSTREAM (High Pressure) DOWNSTREAM (Lower Pressure)

════════════════ ════════════════

10,000 PSI 2,000 PSI

════════════════ ════════════════

│ │

│ ┌──────┐ │

│ │ │ │

└─────►│ ● │────────────┘

│Orifice│ ← Restriction point

└──────┘

High velocity through Lower velocity,

small opening reduced pressure

The Physics Behind Choke Operation

Step 1: High-pressure fluid approaches choke

- Production fluid (oil, gas, water mix) at reservoir pressure

- Pressure: 5,000-15,000 PSI typical

- Flow velocity: relatively low in larger pipe

Step 2: Fluid enters choke restriction

- Flow path suddenly narrows at choke orifice

- Velocity increases dramatically (conservation of energy)

- Kinetic energy increases, pressure energy decreases

Step 3: Fluid exits restriction

- High-velocity jet expands into larger downstream pipe

- Turbulence and friction convert kinetic energy to heat

- Pressure reduces to desired downstream level

- Flow rate controlled by orifice size

Step 4: Controlled flow continues downstream

- Pressure stabilized at safe operating level

- Flow rate matches production requirements

- Equipment protected from over-pressure

Energy Conversion

The choke valve converts:

- Pressure energy → Velocity energy → Heat energy

This energy conversion is why chokes:

- Can get very hot during operation

- Create noise (turbulence)

- Experience erosion over time

- Require special materials

Types of Choke Valves and How They Work

1. Fixed Choke

Design: Non-adjustable orifice of specific size

FIXED CHOKE

════════╪════════

│ ← Fixed orifice

┌───┴───┐ (cannot be changed)

│ ● │

└───┬───┘

════════╪════════

Bean = Fixed internal restriction

How it works:

- Contains a “bean” (removable insert) with fixed orifice

- Orifice size determines flow rate

- To change flow, must replace entire bean

- Simple, reliable, no moving parts

Advantages:

- Simple, rugged design

- No adjustments needed during operation

- Predictable flow rate

- Lower cost

Disadvantages:

- Cannot adjust flow without shutdown

- Must stock multiple bean sizes

- Time-consuming to change

Typical use:

- Stable production wells

- Where flow rate changes are infrequent

- Lower-pressure applications

2. Adjustable Choke

Design: Variable orifice that can be adjusted

ADJUSTABLE CHOKE

Handle/Actuator

│

┌─────┴─────┐

│ Needle │ ← Moves in/out

│ ▼ │

════╪════●════╪════

│ Orifice │ Opening size varies

└───────────┘

Needle position controls

effective orifice size

How it works:

- Needle, plug, or cage moves to vary orifice size

- Opening position controlled manually or automatically

- Larger opening = more flow, less pressure drop

- Smaller opening = less flow, more pressure drop

Adjustment mechanisms:

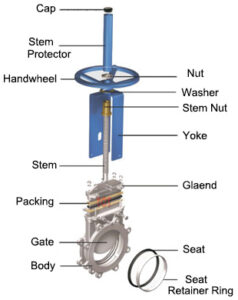

- Manual: Handwheel operator

- Hydraulic: Hydraulic actuator

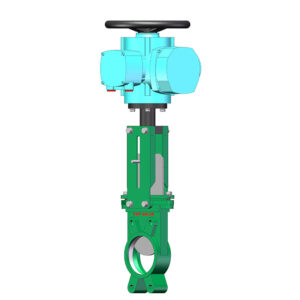

- Pneumatic: Air-powered actuator

- Electric: Motor-driven actuator

Advantages:

- Adjust flow without shutdown

- Fine-tune production rates

- Respond to changing conditions

- No need to replace parts for adjustment

Disadvantages:

- More complex design

- Moving parts subject to wear

- Higher cost

- Requires maintenance

Typical use:

- Wells with changing production rates

- Optimization and testing

- Automatic control systems

- High-value production

3. Positive Choke

Design: Opens in direction of flow (downstream)

How it works:

- Choke element moves with flow direction

- Pressure assists in maintaining seal

- More stable operation

- Less prone to vibration

Advantages:

- Self-sealing (pressure helps close)

- Stable operation

- Better for high-pressure applications

4. Negative Choke

Design: Opens against flow direction (upstream)

How it works:

- Choke element moves against flow

- Requires more force to adjust

- Can be more precise in some designs

Use: Less common, specialized applications

Choke Valve in Wellhead Systems

Wellhead Configuration

A typical wellhead has multiple chokes in the Christmas Tree assembly:

CHRISTMAS TREE WITH CHOKE VALVES

Flow Line

↑

┌─────────┴─────────┐

│ Production Wing │

│ Valve │

├───────────────────┤

│ CHOKE VALVE ←────┼─── Primary pressure control

├───────────────────┤

│ Master Valve │

├───────────────────┤

│ Swab Valve │

└─────────┬─────────┘

│

Wellhead

│

Well Bore

↓

Choke Valve Location and Purpose

In the wellhead, choke valves:

- Control production rate

- Regulate oil and gas flow

- Match processing capacity

- Optimize reservoir performance

- Protect downstream equipment

- Reduce pressure to safe levels

- Prevent separator over-pressure

- Protect pipelines and facilities

- Manage well pressure

- Prevent reservoir damage from too-rapid production

- Maintain bottom-hole pressure

- Control water coning and gas breakthrough

- Enable well testing

- Adjust flow for production tests

- Measure well performance

- Optimize production parameters

- Provide emergency control

- Quick shutdown capability

- Pressure relief if needed

- Safety system integration

How Choke Size Affects Operation

The Orifice Size Relationship

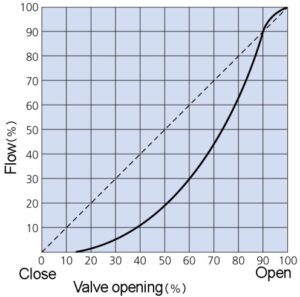

Choke performance depends heavily on orifice size:

| Orifice Size | Flow Rate | Upstream Pressure | Downstream Pressure | Application |

|---|---|---|---|---|

| Large | High | Lower drawdown | Higher | High-volume production |

| Medium | Moderate | Moderate drawdown | Moderate | Typical production |

| Small | Low | Higher drawdown | Lower | Pressure control, testing |

Choke Sizing Calculations

Engineers use specialized formulas to size chokes:

For gas flow:

Q = C × P₁ × √(ΔP / (T × Z × M))

Where:

Q = Gas flow rate

C = Flow coefficient

P₁ = Upstream pressure

ΔP = Pressure drop across choke

T = Temperature

Z = Gas compressibility

M = Molecular weight

For liquid flow:

Q = C × √(ΔP / ρ)

Where:

Q = Liquid flow rate

C = Flow coefficient

ΔP = Pressure drop

ρ = Fluid density

Critical flow: When downstream pressure drops below ~50% of upstream, flow becomes “critical” (sonic) and further pressure reduction doesn’t increase flow.

Factors Affecting Choke Valve Performance

1. Pressure Drop

The fundamental control parameter:

- Larger ΔP = more flow restriction

- Must balance pressure control vs. reservoir damage

- Excessive pressure drop can damage formation

Typical pressure drops:

- Low: 500-1,000 PSI

- Moderate: 1,000-3,000 PSI

- High: 3,000-5,000+ PSI

2. Fluid Properties

Multi-phase flow complexity:

Oil and gas wells produce complex fluid mixtures:

- Oil (liquid)

- Gas (compressible)

- Water (liquid)

- Sand and solids (abrasive)

Each affects choke operation:

- Gas: Expands rapidly through restriction

- Liquids: Don’t compress, create different flow patterns

- Solids: Cause erosion, require hardened materials

- Mixed phases: Create complex flow behavior

3. Erosion

The biggest challenge for choke valves:

High-velocity flow causes severe erosion:

- Sand particles act like sandblasting

- Can erode through metal in weeks

- Worst at choke restriction point

- Requires frequent inspection/replacement

Erosion mitigation:

- Hardened materials (tungsten carbide)

- Erosion-resistant designs

- Regular inspection

- Proper sizing (avoid excessive velocity)

4. Temperature

Chokes experience extreme temperatures:

- Joule-Thomson effect: Gas expansion causes cooling

- Friction heating: Flow restriction generates heat

- Net effect: Can be very hot or very cold

- Consequences: Material stress, ice formation (cold), thermal expansion (hot)

5. Cavitation (Liquids)

Vapor bubble formation and collapse:

When liquid pressure drops below vapor pressure:

- Bubbles form in low-pressure zone

- Bubbles collapse violently downstream

- Creates shock waves

- Damages choke internals

Prevention:

- Proper choke sizing

- Staged pressure reduction

- Anti-cavitation designs

Adjustable Choke Operation

Manual Adjustment Process

Step-by-step adjustment:

- Monitor current conditions

- Upstream pressure

- Downstream pressure

- Flow rate

- Temperature

- Determine required change

- Increase flow? Open choke (larger orifice)

- Decrease flow? Close choke (smaller orifice)

- Calculate new choke setting

- Make adjustment

- Turn handwheel or activate actuator

- Small increments (avoid sudden changes)

- Monitor pressure/flow response

- Stabilize and verify

- Allow system to stabilize (5-15 minutes)

- Verify desired flow rate achieved

- Check for proper operation

- Document new setting

Automatic Choke Control

Automated systems maintain optimal conditions:

AUTOMATIC CHOKE CONTROL LOOP

Pressure Flow Rate

Sensor ────┐ Sensor

│ │

▼ ▼

┌─────────────┐

│ Controller │ ← Setpoints

└──────┬──────┘

│ Control signal

▼

┌─────────────┐

│ Actuator │

└──────┬──────┘

│

┌──────▼──────┐

│ CHOKE VALVE │

└─────────────┘

Control parameters:

- Downstream pressure (most common)

- Flow rate

- Differential pressure

- Temperature

Benefits:

- Continuous optimization

- Rapid response to changes

- Reduced operator workload

- Improved safety

Choke Valve vs Other Control Valves

Choke Valve vs Globe Valve

| Feature | Choke Valve | Globe Valve |

|---|---|---|

| Primary purpose | Pressure reduction in high-pressure service | General flow control |

| Pressure rating | 5,000-15,000+ PSI | Up to ~2,500 PSI typical |

| Erosion resistance | Extreme (hardened materials) | Moderate |

| Precision | Optimized for pressure drop | Optimized for flow control |

| Cost | Very high | Moderate |

| Application | Oil & gas production | General industrial |

Choke Valve vs Control Valve

| Feature | Choke Valve | Control Valve |

|---|---|---|

| Environment | Erosive, high-pressure, multi-phase | Clean, moderate-pressure, single-phase |

| Materials | Tungsten carbide, hardened steel | Standard trim materials |

| Precision | ±5-10% typical | ±1-2% possible |

| Automation | Sometimes automated | Usually automated |

| Maintenance | Frequent (erosion) | Moderate |

Choke Valve Maintenance

Inspection Schedule

Weekly/Monthly:

- Visual inspection for leaks

- Check actuator operation

- Monitor pressure readings

- Review flow data

Quarterly:

- Internal inspection (if possible)

- Check for erosion

- Verify calibration

- Test safety systems

Annually:

- Complete teardown and inspection

- Replace worn components

- Erosion measurement

- Full functional test

Common Problems

| Problem | Symptom | Cause | Solution |

|---|---|---|---|

| Erosion | Increasing pressure drop, leakage | Sand production, high velocity | Replace bean/trim, improve sand control |

| Plugging | Reduced flow, high upstream pressure | Wax, scale, debris | Clean, chemical treatment |

| Leakage | External leaks, loss of control | Seal failure, erosion | Replace seals, repair/replace valve |

| Sticking | Won’t adjust smoothly | Corrosion, deposits | Clean, lubricate, replace if severe |

| Cavitation damage | Pitting, noise, vibration | Improper sizing | Resize choke, staged reduction |

Choke Valve Symbols

Understanding choke valve symbols on P&IDs is essential:

Standard Choke Valve Symbol

CHOKE VALVE P&ID SYMBOLS

Fixed Choke:

───┬─── or ──▼──

● ●

───┴─── (restriction)

Adjustable Choke:

│ (stem)

───┬───

● ← Variable

───┴───

With Actuator:

[M] ← Motor actuator

│

───┬───

●

───┴───

Symbol components:

- Restriction symbol (●, ▼, or similar)

- Stem (adjustable only)

- Actuator symbol (M = motor, A = air, H = hydraulic)

- Flow direction arrow

Production Choke Applications

Typical Production Scenarios

1. New Well Start-Up

Initial choke setting:

- Start with small choke (high restriction)

- Gradually open to increase production

- Monitor reservoir response

- Protect formation from damage

2. Steady-State Production

Optimized flow rate:

- Balance production vs. reservoir pressure

- Maintain equipment within limits

- Maximize recovery

- Minimize operating problems

3. Well Testing

Controlled flow for evaluation:

- Multiple choke sizes tested

- Measure well performance

- Determine optimal production rate

- Build pressure vs. flow curves

4. Pressure Management

Maintain separator pressure:

- Downstream equipment has pressure limits

- Choke maintains safe operating pressure

- Adjusts for changing conditions

5. Emergency Shutdown

Quick flow restriction:

- Close choke rapidly

- Secondary barrier if master valve fails

- Controlled shutdown vs. sudden slam

The Purpose of a Choke Valve

Why Choke Valves Are Essential

What is the purpose of a choke valve?

- Safety: Prevent uncontrolled flow and equipment over-pressure

- Optimization: Balance production rate vs. reservoir performance

- Protection: Shield downstream equipment from excessive pressure

- Control: Enable precise flow and pressure management

- Economics: Maximize production while minimizing problems

Without choke valves:

- Wells could flow uncontrollably

- Equipment would be damaged by over-pressure

- Reservoirs would be damaged by too-rapid production

- Production would be unsafe and inefficient

Frequently Asked Questions

How does a choke valve reduce pressure?

By forcing high-pressure fluid through a small orifice, the choke converts pressure energy into velocity energy and heat through friction and turbulence. The smaller the orifice, the greater the pressure drop.

What’s the difference between a choke valve and a regular valve?

Choke valves are specifically designed for high-pressure, erosive service in oil and gas production. They use hardened materials, specialized geometries for pressure reduction, and are sized/optimized for pressure drop rather than just on/off operation.

Why do choke valves wear out quickly?

The combination of high-velocity flow, abrasive solids (sand), and multi-phase fluids creates extreme erosion. Choke beans can erode through in weeks or months in harsh conditions, requiring frequent replacement.

Can you adjust a fixed choke?

No. Fixed chokes require shutting down and physically replacing the bean with a different size. Adjustable chokes can be changed during operation.

What causes choke valve failure?

Primary causes: erosion from sand production, plugging from wax or scale, seal failure, cavitation damage, and corrosion. Regular inspection and maintenance are essential.

Conclusion

A choke valve works by creating a deliberate, controlled restriction that converts high reservoir pressure into manageable downstream pressure through a precisely sized orifice. This fundamental pressure-control function makes choke valves absolutely essential for safe, optimized oil and gas production.

Key working principles:

- Flow restriction causes pressure drop (fundamental physics)

- Orifice size determines flow rate and pressure reduction

- Fixed chokes use replaceable beans for set restrictions

- Adjustable chokes vary orifice size during operation

- Multi-phase flow and erosion create unique challenges

- Proper sizing balances pressure control, flow rate, and equipment protection

In wellhead operations, choke valves:

- Control production rates from high-pressure reservoirs

- Protect downstream equipment from over-pressure

- Optimize reservoir performance

- Enable well testing and analysis

- Provide emergency flow control

Understanding how choke valves work—from basic pressure-drop principles to complex multi-phase flow behavior—is essential for anyone involved in oil and gas production operations. Proper choke selection, operation, and maintenance directly impact production efficiency, equipment longevity, and operational safety.

Working with wellhead equipment? Always follow proper procedures, use appropriate personal protective equipment, and consult with qualified engineers for choke valve sizing, selection, and operation in your specific conditions.