In the petroleum and natural gas industry, API 6D stands as a crucial design and manufacturing standard for pipeline valves, providing a solid foundation for reliable fluid control during pipeline transportation. Among the various valve types covered by this standard, API 6D ball valves have emerged as a key component, playing a vital role in multiple industrial sectors.

Table of Contents

ToggleDesign Excellence for Unmatched Reliability

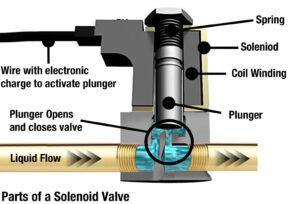

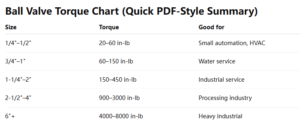

API 6D ball valves are meticulously designed with a strong emphasis on quality and reliability. One of the notable structural features is the availability of both fixed – ball and floating – ball designs. The fixed – ball structure is highly stable in long – distance pipeline high – pressure environments, making it an ideal choice for large – scale oil and gas projects. Its excellent sealing performance ensures minimal leakage, even under extreme pressure conditions. On the other hand, the floating – ball structure is well – suited for lower – pressure and smaller – diameter applications. It offers the advantages of easy installation and maintenance, reducing downtime and operational costs.

In terms of material selection, API 6D ball valves are crafted from high – strength carbon steel and stainless steel. These materials are chosen for their ability to withstand a wide range of pressure and temperature conditions. Rigorous testing procedures are implemented to guarantee the stability of the valves under different operating scenarios, ensuring long – term and reliable performance.

The functional design of API 6D ball valves is also unique. For example, some models feature a double – seal structure, which significantly enhances the sealing effect. This design not only reduces torque requirements during operation, making the valves easier to handle, but also ensures a high level of safety in fluid control.

Stringent Manufacturing Quality Control

The manufacturing process of API 6D ball valves is subject to strict quality control measures. Heat treatment, a critical step, demands a standardized process flow, including preheating, heat treatment itself, and subsequent inspection. There are clear regulations regarding the qualifications of heat treatment equipment and operators. According to API 6D 24th edition Appendix F, calibration of equipment is required annually at both the maximum and minimum operating temperatures. Temperature deviations must be controlled within ±25°F (±13°C), and for furnaces used for tempering and stress relief, the deviation should be within ±15°F (±8°C). Additionally, control and recording equipment must maintain high precision, with deviations within ±1% of the full – scale range.

Diverse Applications Across Industries

Petroleum and Natural Gas Production

API 6D ball valves are widely used in gas and oil well production facilities. Natural gas and oil production systems often face extremely high pressures, sometimes up to 10,000 psi, especially in deep – sea oil wells. The valve – pipeline combinations need to withstand these extreme conditions, and API 6D ball valves, along with globe valves, are commonly employed. In oil field pre – treatment equipment, lower – grade carbon steel ball valves are often used to meet the specific requirements of the process.

Offshore Production Facilities

On offshore oil platforms and drilling equipment, the multiple specifications and structures of API 6D ball valves cater to complex flow control needs. API 6D ball valves and check valves are used on platforms to separate gas and liquid and remove moisture from hydrocarbons. These valves are mainly installed in the internal pipelines of the platforms, although not for high – standard external pipelines.

Environmental Protection Equipment

API 6D American standard ball valves also perform well in environmental protection equipment. Their hydraulic double – wheel drive design and double – wheel vibration characteristics result in excellent compaction performance and high adaptability, making them suitable for various environmental protection applications.

Other Industries

In addition to the oil and gas and environmental protection sectors, API 6D ball valves are widely applied in power generation, water treatment, and commercial building industries. Power plant auxiliary pipelines, water treatment plants, and wastewater systems often require different types of valves to meet various pressure and operational requirements, and the diverse designs of API 6D ball valves make them a suitable choice.

Comparison with Other API Standards

Compared to API 608, API 6D is specifically designed for long – distance pipelines. It offers multiple functions such as blowdown, venting, and over – pressure relief. The ball valves under API 6D mainly adopt a fixed – ball structure to meet the demands of high – pressure and large – diameter applications. In contrast, API 608 is mainly used for small – diameter and low – pressure situations, and its ball valves are generally of the floating – ball type. API 6D also differs from API 608 in terms of pressure ratings, diameter ranges, structural designs, and inspection requirements.

Furthermore, when compared with other API standards, API 6D is more inclined towards long – distance pipeline applications. API 600 is mainly used for gate valves, API 594 focuses on check valves, API 607 is dedicated to the fire – resistance of fire – proof valves, and API 527 sets the sealing performance test standards for pressure relief valves.

Future Prospects

The application of API 6D ball valves in the industry is set to expand further. With the development of deep – sea oil and gas resources and the increasing demand for environmental protection equipment, the market demand for API 6D ball valves is expected to rise steadily. Future technological innovations will focus on improving the corrosion resistance and intelligence level of the valves, thereby enhancing operational efficiency and safety. API 6D ball valves will continue to play a significant role in the global market, and domestic enterprises should strengthen technological innovation and quality control to improve product competitiveness and actively explore international markets.

In conclusion, API 6D ball valves, with their strict standards and high – quality assurance, are a reliable choice in multiple industrial fields, and their future application prospects are extremely broad.