Anti-siphon valves play a vital role in plumbing, irrigation, and fuel systems by preventing unwanted reverse flow, contamination, and siphoning. But how exactly do anti-siphon valves work? What physical principles and mechanical components allow them to break a siphon effectively?

This guide offers a complete, engineering-level explanation of the anti-siphon working principle, complete with diagrams, real-world examples, and system-specific variations.

Table of Contents

Toggle1. The Science Behind Siphoning

To understand an anti-siphon valve, we must first understand what causes siphoning.

Siphoning occurs when:

Downstream pressure drops below upstream pressure

A vacuum or negative pressure is created

Fluid reverses direction unexpectedly

Gravity assists reverse flow

This is common when:

A hose is submerged in a bucket

A sprinkler line shuts off

Water is drawn suddenly elsewhere in the system

Fuel lines experience pressure imbalance

When pressure at the outlet becomes lower than at the inlet, fluid is pulled backward — unless something stops it.

An anti-siphon valve breaks the vacuum before backflow starts.

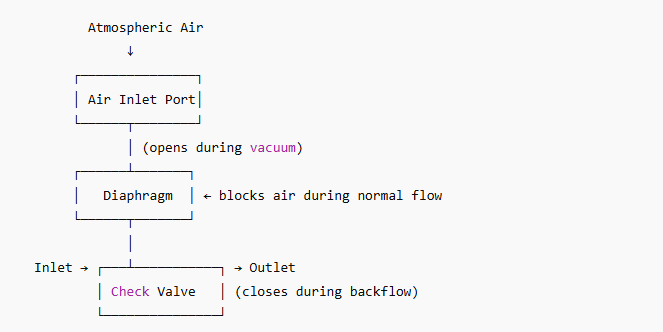

2. The Fundamental Working Principle

Regardless of type, all anti-siphon valves work on the same core principle:

➡ When a vacuum is detected, the valve introduces air and blocks reverse flow.

This two-step reaction is what makes siphoning impossible:

Air enters the system through an atmospheric port

Reverse flow is mechanically blocked using a check mechanism, diaphragm, or spring-loaded valve

By allowing air to enter, the anti-siphon valve breaks the continuous column of fluid that makes siphoning possible.

3. Key Internal Components

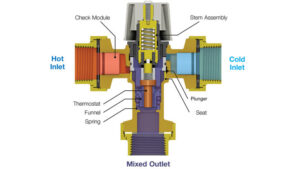

Although designs differ by application, most anti-siphon valves contain:

1. Air inlet / vacuum breaker

Allows outside air to enter the system when pressure drops.

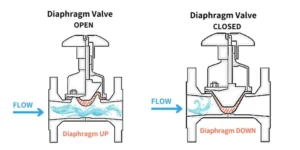

2. Float, plunger, or diaphragm

Moves in response to pressure changes.

3. Spring-loaded check valve

Ensures fluid flows only in one direction.

4. Atmospheric opening

Exposed to ambient air, only opens during vacuum.

5. Flow-through body

Connects inlet and outlet fluid lines.

4. How an Anti-Siphon Valve Works (Step-by-Step)

Normal Operation (Forward Flow)

System is pressurized

Water or fuel flows through normally

Internal diaphragm/plunger blocks the air inlet

Check valve opens to allow forward flow

No air enters. No obstruction exists. Everything is normal.

Unpressurized Condition (System Off)

Pressure inside drops to zero

Internal diaphragm falls due to gravity

Air inlet opens automatically

This prevents a vacuum from forming — even before backflow begins.

Vacuum Formation (Backflow Risk)

If a vacuum occurs — for example, when:

A hose end is lower than the supply

Pump stops suddenly

A sprinkler solenoid valve closes quickly

A fuel tank experiences suction

Then:

1. Internal pressure is lower than atmospheric pressure

Atmospheric air begins pushing inward.

2. Air inlet opens fully

Air breaks the siphon immediately.

3. Check valve closes

Reverse flow is physically blocked.

Result: No siphon can form. No contamination or reverse flow is possible.

5. Working Principle by Application Type

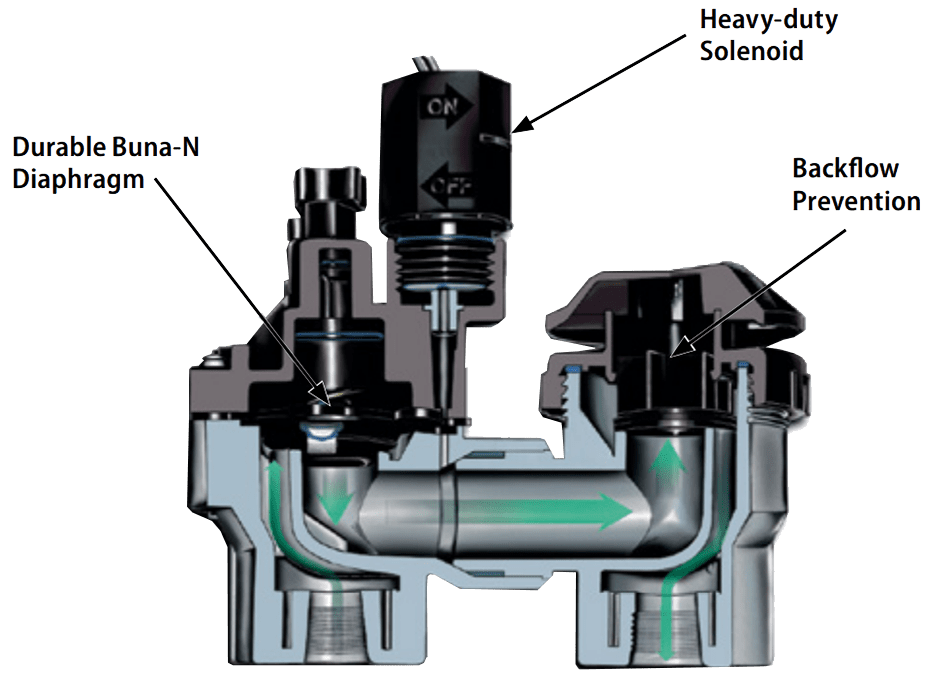

A. Irrigation Anti-Siphon Valve — How It Works

Used in sprinkler systems, often combining a solenoid valve and vacuum breaker.

Working steps:

Sprinkler controller energizes the solenoid → valve opens

Water flows normally → diaphragm seals air port

System shuts off → pressure drops

Air inlet opens → vacuum is broken

Soil, fertilizer, or dirty water cannot flow backward

Important:

Anti-siphon irrigation valves must be installed 6–12 inches above the highest sprinkler head to work correctly.

B. Hose Bib Anti-Siphon Device — How It Works

Also called a hose bib vacuum breaker.

Working steps:

Water flows forward; check valve opens

Back pressure pushes the check valve shut

Vacuum opens the atmospheric port

Air rushes in and prevents siphon

This type protects household drinking water.

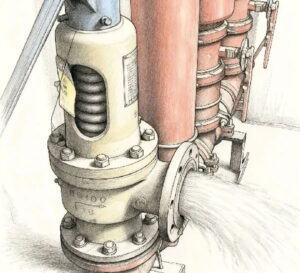

C. Fuel Tank Anti-Siphon Valve — How It Works

Used on:

Boats

Cars

Diesel storage tanks

Generators

Its working principle focuses on fuel theft prevention and leak protection.

Working steps:

Fuel pump creates forward pressure → valve opens

Reverse suction triggers the internal spring

Valve slams shut to block backwards flow

Air admittance may not be used (due to fuel safety)

Reverse siphoning becomes impossible

This prevents thieves from siphoning fuel using hoses.

6. Anti-Siphon Valve Diagram (Text Version)

7. Common Misconceptions About Anti-Siphon Valves

❌ Misconception 1:

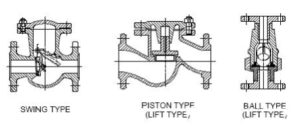

“An anti-siphon valve is just a check valve.”

✔ Reality:

A check valve blocks reverse flow,

but an anti-siphon valve breaks the vacuum and blocks reverse flow.

❌ Misconception 2:

“Any valve installed high will stop siphoning.”

✔ Reality:

Height helps, but vacuum breakers are mandatory for contamination prevention.

❌ Misconception 3:

“Anti-siphon valves only belong in irrigation.”

✔ Reality:

They are used in:

Plumbing

Fuel tanks

Boats

Industrial equipment

Air conditioning systems

Chemical transfer lines

8. Signs an Anti-Siphon Valve Is Not Working

Dripping or leaking water

Low sprinkler pressure

Water flowing backward when system shuts off

Fuel odor near tank

Siphoning incidents

Air hissing unexpectedly

Hose bib dripping after shutoff

A malfunctioning anti-siphon valve must be repaired or replaced immediately.

9. Summary: How an Anti-Siphon Valve Works

An anti-siphon valve prevents reverse flow by:

Detecting vacuum conditions

Opening an air inlet

Allowing atmospheric air to break siphon action

Closing a check valve to stop backflow

This mechanism protects:

Drinking water

Irrigation systems

Fuel tanks

Industrial pipelines

It is one of the simplest, most reliable, and most important safety devices in fluid engineering.