Table of Contents

ToggleQuick Answer

A thermostatic mixing valve (TMV) is a valve that blends hot water with cold water to ensure constant, safe shower and bath outlet temperatures to prevent scalding. It automatically adjusts the mix ratio to maintain your preset temperature, even when supply pressures or temperatures fluctuate.

Key benefit: Prevents scalding burns while allowing water heaters to operate at higher, bacteria-killing temperatures.

What Is a Thermostatic Mixing Valve?

Simple Explanation

A thermostatic mixing valve is like a smart gatekeeper for your hot water. It takes scorching hot water from your water heater and mixes it with cold water to deliver safe, comfortable water at exactly the temperature you want—no manual adjustment needed.

The Problem It Solves

Without a TMV:

- Water heater set to 140°F (safe from bacteria)

- Turn on shower → Risk of scalding burns

- Lower water heater temp → Bacteria growth (Legionella)

- Constant temperature adjustment needed

With a TMV:

- Water heater stays at 140°F (kills bacteria)

- TMV automatically mixes to safe 120°F or below

- Consistent temperature regardless of pressure changes

- No scalding risk

How It’s Different from Regular Valves

| Feature | Regular Mixing Valve | Thermostatic Mixing Valve |

|---|---|---|

| Temperature control | Manual adjustment needed | Automatic temperature regulation |

| Consistency | Varies with pressure changes | Maintains set temperature |

| Scald protection | None | Built-in protection |

| Response time | Slow (manual) | Instant (automatic) |

| Cost | $20-50 | $100-500+ |

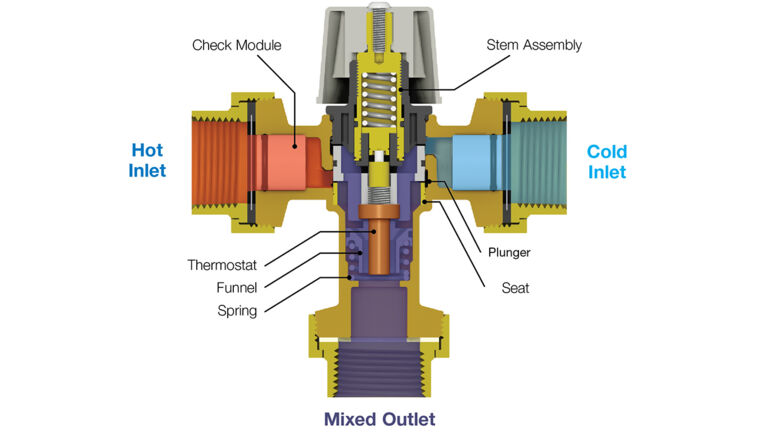

How Does a Thermostatic Mixing Valve Work?

The Basic Mechanism

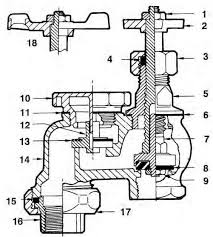

At the heart of every TMV is a temperature-sensitive element that expands and contracts with temperature changes. This element automatically adjusts the valve’s internal mechanism to maintain your preset output temperature.

Step-by-Step Process

1. Hot and cold water enter the valve

Hot Water (140°F) → ┐

├─→ Mixing Chamber

Cold Water (50°F) → ┘

2. Temperature sensor monitors output

- Wax-filled element or bimetallic coil

- Expands when hot, contracts when cold

- Controls internal valve position

3. Valve adjusts mix ratio automatically

If water gets too hot:

Hot Water valve → Closes slightly

Cold Water valve → Opens more

Result: Cooler output

If water gets too cold:

Hot Water valve → Opens more

Cold Water valve → Closes slightly

Result: Warmer output

4. Consistent temperature delivered

- Set point: 120°F

- Output: 120°F ± 2°F

- Regardless of supply fluctuations

Types of Thermal Actuators

Wax-Filled Element (Most Common)

- Paraffin wax expands when heated

- Fast response time (2-3 seconds)

- Highly accurate (±2°F)

- Long lifespan (10-15 years)

- Used in most modern TMVs

Bimetallic Coil

- Two metals expand at different rates

- Slower response (5-10 seconds)

- Less expensive

- Older technology

Digital/Electronic

- Electronic temperature sensor

- Motor-driven valve adjustment

- Most precise (±1°F)

- Requires power

- Most expensive

Safety Features

Cold Water Fail-Safe In the event of a loss of cold water, valves will shut off completely and not allow any flow at all.

- Prevents scalding from hot-only water

- Automatic shutoff if cold supply fails

Hot Water Fail-Safe

- Allows cold water bypass

- Ensures water availability in emergencies

- Important for safety equipment

Temperature Limit Stop

- Physical maximum temperature setting

- Cannot be exceeded even if adjusted

- Typically set at 120°F for residential use

Types of Thermostatic Mixing Valves

1. Point-of-Use TMVs (Individual Fixtures)

What they are: Single Outlet Thermostatic Mixing Valves, often called “thermostatic faucets”, “thermostat taps” or “thermostat valves”. Designed for single point applications, such as individual showering, hand wash basin mixers, bath or tub fillers.

Best for:

- ✅ Individual showers

- ✅ Bathroom sinks

- ✅ Bathtub faucets

- ✅ Kitchen sinks

Advantages:

- Each fixture has independent temperature control

- Easy to replace individual units

- No effect on other fixtures if one fails

Disadvantages:

- More expensive (multiple units needed)

- More maintenance points

- Takes up space at each fixture

Typical cost: $100-300 per fixture

2. Central/Master TMVs (Whole System)

What they are: Installed at the water heater or main distribution point to temper all hot water leaving the source.

Best for:

- ✅ Whole-house temperature control

- ✅ Multi-unit buildings

- ✅ Healthcare facilities

- ✅ Schools and daycare centers

Advantages:

- One valve protects entire system

- Lower overall cost for multiple fixtures

- Easier centralized maintenance

- Consistent building-wide temperature

Disadvantages:

- Single point of failure affects all fixtures

- More complex installation

- Requires larger valve (higher flow capacity)

Typical cost: $300-800 for residential, $1,000-3,000 for commercial

3. Emergency Equipment TMVs

What they are: Specialized valves for emergency eyewash stations, safety showers, and drench equipment.

Key features:

- Precision wax-filled thermal actuator to precisely blend hot and cold water to the desired tepid temperature

- High flow capacity (15-60 GPM)

- ANSI Z358.1 compliant (tepid water 60-100°F)

- Bypass mode if hot water fails

Required locations:

- Chemical labs

- Industrial facilities

- Healthcare facilities

- Manufacturing plants

Typical cost: $500-2,000 depending on flow capacity

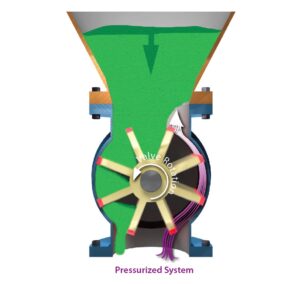

4. Recirculation System TMVs

What they are: Valves designed for hot water recirculation loops to maintain bacteria-free temperatures while delivering safe outlet temperatures.

Purpose:

- Keep supply water above 131°F (prevents Legionella)

- Deliver outlet water at safe 120°F or below

- Maintain circulation loop temperature

Best for:

- Large buildings with long pipe runs

- Healthcare facilities

- Hotels and commercial buildings

Typical cost: $400-1,500

Where Thermostatic Mixing Valves Are Used

Residential Applications

Required by code in many areas:

- ✅ New construction homes

- ✅ Homes with young children or elderly

- ✅ Bathroom remodels

- ✅ Multi-family dwellings

Common installation points:

Whole-house protection:

- At water heater outlet

- Before distribution manifold

- Protects all fixtures

Individual fixtures:

- Shower valves

- Bathtub fillers

- Bathroom sink faucets

- Washing machine connections

Commercial Applications

Healthcare Facilities Thermostatic mixing valves are the preferred type in health care facilities, as they limit maximum outlet temperature, regardless of pressure or flow.

Required locations:

- Patient room showers

- Therapy pools

- Hand-washing stations

- Bathing areas

Why critical:

- Vulnerable populations (elderly, disabled)

- Liability concerns

- Infection control (high storage temps)

- Code requirements

Schools and Daycare Centers

Typical requirements:

- All student-accessible fixtures

- Maximum 120°F outlets

- Central TMV for building

- Regular testing and maintenance

Industrial and Laboratory

Safety equipment:

- Emergency eyewash stations (tepid water required)

- Safety showers

- Drench hoses

- Face wash stations

Code requirement:

- ANSI Z358.1 standard

- Tepid water (60-100°F)

- Must function during emergencies

Benefits of Thermostatic Mixing Valves

1. Scald Prevention

Statistics:

- Most tap water scalds occur in under 5 seconds at 140°F

- At 120°F, scalding takes 5-8 minutes

- TMVs reduce scald injuries by 70-90%

Who’s most at risk:

- Children under 5 (thin skin)

- Adults over 65 (slower reaction time)

- People with disabilities

- Anyone with reduced sensation

2. Legionella Prevention

The problem:

- Legionella bacteria thrives at 77-113°F

- Causes Legionnaires’ disease (potentially fatal)

- Grows in water heaters and pipes

The solution:

- Store water at 140°F+ (kills bacteria)

- Use TMV to deliver safe 120°F at outlets

- The storage of water at high temperature removes one possible breeding ground for Legionella

3. Energy and Water Savings

How it saves:

- Water heater runs more efficiently at higher temps

- Less mixing needed for comfort

- Reduced hot water waste from adjusting temperature

- Faster hot water delivery

Estimated savings:

- 10-15% reduction in hot water usage

- Lower energy bills

- Extended water heater life

4. Consistent Comfort

Eliminates common problems:

- ❌ Temperature spikes when toilet flushes

- ❌ Cold blasts when someone uses water elsewhere

- ❌ Gradual temperature drift during shower

- ❌ Different temperatures at different times

Result:

- ✅ Set it once, forget it

- ✅ Same temperature every time

- ✅ No adjustment needed during use

5. Code Compliance

Many jurisdictions now require TMVs for:

- New residential construction

- Bathroom remodels

- Multi-family buildings

- All commercial facilities

- Healthcare and educational facilities

Many countries, states, or municipalities now require that the temperature of all bath water in newly built and extensively refurbished domestic properties be controlled to a maximum of 48 °C (118 °F).

Installation Considerations

Where to Install

Option 1: Master Mixing Valve (Most Common)

Location: At or near water heater

Water Heater (140°F) → TMV → Distribution → All Fixtures (120°F)

Advantages:

- Protects entire home

- One valve to maintain

- Most cost-effective for new construction

Disadvantages:

- Single point of failure

- May need larger valve for whole-house flow

Option 2: Zone Mixing Valves

Location: At manifolds serving specific areas

Water Heater → Hot Manifold → TMV for Bathrooms → Bathroom Fixtures

→ TMV for Kitchen → Kitchen Fixtures

Advantages:

- Different temperatures for different areas

- Partial system failure won’t affect everything

- Better for large homes

Option 3: Point-of-Use

Location: At each individual fixture

Advantages:

- Maximum control per fixture

- Easy to replace

- Works with existing systems

Disadvantages:

- Most expensive option

- More maintenance needed

- More installation labor

Installation Requirements

Essential components:

- Shut-off valves

- On both hot and cold supply lines

- Allows service without draining system

- Ball valves preferred (full flow)

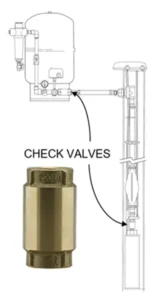

- Check valves

- Check valves assure flow of water in one direction. They prevent thermal siphoning of hot water to the cold water supply.

- Required for ASSE 1017 compliance

- Install on both supply lines

- Strainers/filters

- Protect valve from debris

- Especially important in new construction

- 100-mesh minimum recommended

- Pressure gauges

- Monitor inlet and outlet pressures

- Help diagnose problems

- Required for some commercial applications

- Temperature gauge

- Verify outlet temperature

- Essential for testing and maintenance

- Mount 5-8 feet downstream for accuracy

Sizing the Valve

Key factors:

Flow rate requirements:

- Calculate total simultaneous flow demand

- Include all fixtures served by valve

- Add 20% safety margin

Typical fixture flows:

- Shower: 2.5 GPM

- Bathtub: 4 GPM

- Bathroom sink: 1.5 GPM

- Kitchen sink: 2.5 GPM

- Washing machine: 3 GPM

Example calculation:

2 Showers: 2.5 × 2 = 5 GPM

2 Sinks: 1.5 × 2 = 3 GPM

1 Tub: 4 GPM

Total: 12 GPM

With 20% margin: 14.4 GPM

Choose valve rated for 15 GPM minimum

Pressure requirements:

- Minimum inlet pressure: 25-30 PSI

- Recommended: 40-80 PSI

- Check valve specifications

Installation Best Practices

1. Proper orientation

- Install valve in correct position (usually horizontal)

- Follow manufacturer’s arrow direction

- Ensure thermal element is oriented correctly

2. Adequate spacing

- Leave room for service access

- 12-18 inches clearance recommended

- Access to adjustment mechanisms

3. Pressure balance

- Hot and cold supply pressures should be similar

- Install pressure-reducing valves if needed

- Maximum 10 PSI difference recommended

4. Temperature testing

- Test at multiple flow rates

- Verify at all fixtures served

- Document initial settings

5. Labeling

- Label valve location

- Document settings

- Note service date

- Include contact for maintenance

ASSE Standards and Code Requirements

Understanding ASSE Standards

ASSE (American Society of Sanitary Engineering) sets performance standards for plumbing devices including TMVs.

ASSE 1016 – Point-of-Use Valves

Application: Individual fixture protection

Requirements:

- ASSE 1016 listed valves provide the user with both scald protection and thermal shock protection.

- Maximum outlet temperature variance: ±3°F

- Automatic shutdown if cold water fails

- Thermal shock protection

Where required:

- Showers and tub/shower combinations

- Bathtubs (new construction)

- Healthcare patient areas

- Childcare facilities

ASSE 1017 – Master Mixing Valves

Application: Central/whole-house protection

Requirements:

- Protects multiple fixtures

- Maintains set temperature under varying flow

- Requires check valves on inlet

- Pressure rating 125 PSI minimum

Where required:

- Multi-family residential

- Commercial buildings

- Healthcare facilities

- These valves can also be used for re-circulation systems to maintain domestic hot water supply temperatures at levels (temperatures above 55C (131F) that prevent the growth of harmful bacteria such as Legionella.

ASSE 1070 – Emergency Equipment

Application: Safety showers and eyewash stations

Requirements:

- ASSE 1070 listed valves provide the user with scald protection only.

- Tepid water delivery (60-100°F)

- High flow capacity

- Fail-safe operation

Where required:

- Emergency eyewash/shower stations

- Laboratory facilities

- Industrial safety equipment

- Compliance with ANSI Z358.1

ASSE 1071 – Temperature Actuated Valves

Application: Emergency equipment with automatic temperature control

Requirements:

- Automatic temperature limiting

- Suitable for emergency equipment

- High reliability in emergency conditions

Maximum Temperature Requirements by Code

International Plumbing Code (IPC):

- Shower/tub: 120°F maximum

- Public facilities: 110°F maximum

- Healthcare: varies by state (usually 110-120°F)

State and local codes:

- California: 120°F maximum (residential showers)

- New York: 120°F maximum (new construction)

- Florida: 120°F maximum (childcare facilities)

- Check local requirements—they vary significantly

Maintenance and Troubleshooting

Regular Maintenance Schedule

Monthly:

- Check for leaks

- Verify temperature at outlets

- Listen for unusual noises

Annually:

- Regular inspection of mixing valves is recommended to assure maximum valve life and a properly functioning system.

- Test temperature accuracy (at multiple flows)

- Clean strainers/filters

- Check pressure gauges

- Inspect for corrosion

- Verify shut-off valves operate

- Document findings

Every 3-5 Years:

- Replace internal seals (if accessible)

- Rebuild or replace valve (if needed)

- Update documentation

- Review code compliance

Common Problems and Solutions

Problem 1: Inconsistent Temperature

Symptoms:

- Temperature fluctuates during use

- Different each time you use fixture

- Takes long time to stabilize

Possible causes: □ Clogged strainer/filter □ Pressure imbalance (hot vs cold) □ Worn thermal element □ Incorrect valve sizing (too small)

Solutions:

- Clean or replace strainer

- Check and balance supply pressures

- Test thermal element response time

- Verify flow demand vs valve capacity

Problem 2: Water Too Hot

Symptoms:

- Outlet temperature exceeds setpoint

- Scalding risk

- Adjustment doesn’t help

Possible causes: □ Incorrect temperature setting □ Failed thermal element □ Obstruction in cold water supply □ Check valve failure (backflow)

Solutions:

- Verify and reset temperature adjustment

- Test thermal element with thermometer

- Check cold water supply valve is fully open

- Inspect check valves for debris/failure

- Replace valve if thermal element failed

Problem 3: Water Too Cold

Symptoms:

- Outlet temperature below setpoint

- Cannot achieve desired warmth

- Lukewarm only

Possible causes: □ Water heater temperature too low □ Hot water supply restriction □ Incorrect valve sizing (too large) □ Thermal element over-compensating

Solutions:

- Check water heater setpoint (should be 140°F)

- Verify hot water supply valve fully open

- Clean hot water side strainer

- Recalibrate temperature adjustment

- Verify valve size matches application

Problem 4: No Water Flow

Symptoms:

- Valve completely closed

- No hot or cold water

- Other fixtures work fine

Possible causes: □ Cold water failure (safety shutoff activated) □ Both supply valves closed □ Complete valve failure □ Debris blockage

Solutions:

- Check both supply shut-off valves are open

- Verify cold water supply to building

- Remove and clean strainers

- If safety shutoff: restore cold water, reset valve

- Replace valve if internal failure

Problem 5: Leaking from Valve Body

Symptoms:

- Water dripping from valve

- Moisture around connections

- Water damage below valve

Possible causes: □ Loose connections □ Worn seals or O-rings □ Cracked valve body (freeze damage) □ Over-tightened fittings

Solutions:

- Tighten connections carefully (don’t over-tighten)

- Replace accessible seals/O-rings

- If cracked: replace entire valve

- Check for freeze damage if in cold climate

When to Replace vs Repair

Replace the valve if:

- ✅ Thermal element has failed

- ✅ Valve body is cracked or corroded

- ✅ Valve is over 15 years old

- ✅ Repair cost exceeds 50% of new valve

- ✅ Cannot achieve temperature accuracy

- ✅ No longer meets current codes

Repair/maintain if:

- ✅ Simple cleaning/filter replacement needed

- ✅ Valve is less than 10 years old

- ✅ Only seals or O-rings need replacement

- ✅ Minor adjustment solves problem

- ✅ Manufacturer provides repair kits

Choosing the Right TMV

Key Selection Criteria

1. Application type

- Point-of-use vs. central mixing

- Residential vs. commercial

- Emergency equipment needs

2. Flow capacity

- Calculate total demand

- Include simultaneous use

- Add 20% safety margin

3. Temperature range

- Maximum inlet temperature rating

- Desired outlet temperature

- Adjustment range needed

4. Code compliance

- Check local requirements

- ASSE standard needed (1016, 1017, 1070)

- Listing requirements

5. Features needed

- Anti-scald protection

- Thermal shock protection

- Fail-safe operation

- Bypass capability (emergency equipment)

Budget Considerations

Entry-level ($100-200):

- Basic point-of-use valves

- Residential applications

- Simple mechanical operation

- Limited adjustability

Mid-range ($200-500):

- Better quality construction

- Wider adjustment range

- Commercial-grade

- Easier maintenance

Premium ($500-1,500+):

- Highest accuracy and reliability

- Digital/electronic control options

- Easy calibration and adjustment

- Extended warranties

- Best for critical applications

Emergency equipment ($800-3,000):

- ASSE 1070 or 1071 listed

- High flow capacity

- Fail-safe features

- Required for safety stations

Top Manufacturers

Residential/Commercial:

- Leonard Valve (Honeywell)

- Watts

- Symmons

- Lawler

- Powers

- Bradley

Emergency Equipment:

- Guardian Equipment

- Haws Corporation

- Bradley

Premium/Digital:

- Watts (digital models)

- Honeywell (smart valves)

- Caleffi

Frequently Asked Questions

Is a thermostatic mixing valve required by code?

It depends on your location and application. Many jurisdictions require TMVs for new construction, bathroom remodels, or buildings with vulnerable populations (schools, healthcare). Check with your local building department for specific requirements.

Can I install a TMV myself?

If you have plumbing experience, yes—but check local codes first. Many areas require licensed plumbers for any water heater work. TMV installation involves working with hot water systems and must be done correctly for safety.

What temperature should I set my TMV to?

For residential applications:

- Showers/tubs: 120°F maximum (110°F for young children/elderly)

- Kitchen sinks: 120°F

- Washing machines: Can be higher if needed

These valves should never be set to exceed a maximum temperature of 49C (120F). (Watts recommends the maximum temperature of 43C (110F) for shower and bathing fixtures.)

How often do TMVs need maintenance?

- Testing: Annually minimum

- Filter cleaning: Every 6-12 months

- Full service: Every 3-5 years

- Replacement: Every 10-15 years

Professional testing required for commercial/healthcare applications.

Can a TMV save me money?

Yes, in several ways:

- Reduced hot water waste (less mixing/adjustment)

- More efficient water heater operation

- Extended water heater lifespan

- Potential insurance discounts

Typical savings: 10-15% on hot water energy costs.

What’s the difference between a TMV and a tempering valve?

These terms are often used interchangeably, but technically:

- TMV: Actively maintains temperature with thermal element

- Tempering valve: May be simpler mixing without active control

Always verify the valve has thermostatic control (temperature-sensing element) for maximum safety.

Will a TMV work with a tankless water heater?

Yes, but it may not be necessary. Many tankless heaters have built-in temperature controls. However, a TMV can provide additional protection and is still beneficial for:

- Multiple fixture systems

- Code compliance

- Added safety layer

- Consistent temperature across all fixtures

Do I still need my water heater at 140°F?

Yes, for safety reasons:

- Kills Legionella bacteria

- Prevents bacterial growth in tank

- Provides effective hot water capacity

The TMV then safely delivers 120°F to fixtures. This is the recommended best practice.

Conclusion

Thermostatic mixing valves are essential safety devices that protect against scalding while allowing water heaters to operate at bacteria-killing temperatures. Whether required by code or chosen for safety, a properly installed and maintained TMV provides:

Key benefits:

- ✅ Scald prevention (especially for vulnerable populations)

- ✅ Legionella bacteria control

- ✅ Consistent, comfortable water temperature

- ✅ Energy and water savings

- ✅ Code compliance