Table of Contents

ToggleQuick Answer

Water shut off valves come in three main categories: by mechanism (gate, ball, globe), by location (main, fixture, appliance), and by material (brass, bronze, plastic). Ball valves are the modern standard for reliability, while gate valves are common in older homes. Choose based on your application, flow requirements, and budget.

Most common: Ball valves (quarter-turn, reliable), Gate valves (multi-turn, older homes), Angle stops (under sinks and toilets).

Understanding Valve Types

Why Valve Type Matters

Different water shut off valves serve different purposes throughout your home’s plumbing system. Using the right type ensures:

- Reliable operation when you need it

- Appropriate flow capacity

- Longevity and durability

- Compliance with building codes

- Ease of maintenance

The wrong valve can lead to: Leaks, inability to shut off water during emergencies, premature failure, and costly repairs.

Types by Mechanism

1. Ball Valves (Quarter-Turn)

How they work: A ball with a hole through the center rotates inside the valve. When the hole aligns with the pipe, water flows. A quarter-turn perpendicular blocks flow completely.

Visual identification:

- Lever handle

- Single quarter-turn operation

- Handle parallel to pipe = OPEN

- Handle perpendicular to pipe = CLOSED

Advantages:

- ✅ Fast operation (quarter-turn)

- ✅ Clear visual on/off indicator

- ✅ Highly reliable (rarely fail)

- ✅ Works after years of non-use

- ✅ Full flow with minimal restriction

- ✅ Durable (20-30 year lifespan)

Disadvantages:

- ❌ More expensive initially ($15-40)

- ❌ Handle can break (though body still works)

Best applications:

- Main water shut offs

- New construction or replacements

- Anywhere reliability is critical

- High-pressure applications

Cost: $15-40 (residential), $50-200 (commercial)

2. Gate Valves (Multi-Turn)

How they work: A wedge-shaped gate slides up and down inside the valve body. Turning the wheel lifts the gate (open) or lowers it (closed). Requires multiple full rotations.

Visual identification:

- Round wheel-shaped handle

- Requires 5-10 full turns to operate

- No visual on/off indication

- Usually brass or bronze body

Advantages:

- ✅ Full flow when open (no restriction)

- ✅ Durable design

- ✅ Lower initial cost ($10-30)

- ✅ Good for larger pipe sizes

Disadvantages:

- ❌ Slow to operate (many turns)

- ❌ Internal gate can stick or corrode

- ❌ May leak after years of non-use

- ❌ Requires periodic exercise (testing)

- ❌ No visual position indicator

Best applications:

- Older homes (already installed)

- Large diameter pipes (2″+)

- Infrequent operation

- Budget-conscious installations

Cost: $10-30 (residential), $40-100 (commercial)

Important: Many plumbing codes now require ball valves instead of gate valves for new installations.

3. Globe Valves

How they work: An internal disc moves up and down against a valve seat. The disc compresses onto the seat to stop flow. Can be positioned anywhere between fully open and fully closed.

Visual identification:

- Round handle (similar to gate valve)

- Bulbous, spherical body shape

- Usually smaller than gate valves

- Often has arrows indicating flow direction

Advantages:

- ✅ Excellent for throttling (flow control)

- ✅ Precise flow adjustment

- ✅ Good shutoff seal

- ✅ Available in many sizes

Disadvantages:

- ❌ Restricts flow even when fully open

- ❌ Higher pressure drop than gate or ball valves

- ❌ Not ideal for main shutoffs

- ❌ More complex internal design

Best applications:

- Flow control applications

- Hose bibbs (outdoor faucets)

- Where precise regulation needed

- Not typically used for main shutoffs

Cost: $15-40

4. Angle Stop Valves

How they work: Combination of globe valve mechanism in a 90-degree angle body. Input and output connections are perpendicular to each other.

Visual identification:

- L-shaped or 90-degree angle design

- Small, compact size

- Usually chrome-plated

- Found under sinks and behind toilets

Advantages:

- ✅ Space-saving design

- ✅ Combines shutoff and direction change

- ✅ Easy to install in tight spaces

- ✅ Eliminates need for elbow fitting

Disadvantages:

- ❌ Only suitable for fixture connections

- ❌ Not for main lines

- ❌ Limited size range (typically 1/2″ or 3/8″)

Best applications:

- Under bathroom and kitchen sinks

- Behind toilets

- Washing machine connections

- Individual fixture control

Types of angle stops:

- Multi-turn (traditional)

- Quarter-turn (modern, more reliable)

- Compression connection (no soldering)

- Sweat connection (soldered)

Cost: $5-15 each

5. Butterfly Valves

How they work: A disc rotates on a shaft inside the valve body. When perpendicular to flow, it blocks water. When parallel, water flows around it.

Visual identification:

- Thin, wafer-style body

- Lever or gear operator

- Large diameter capabilities

- Compact compared to gate valves

Advantages:

- ✅ Lightweight and compact

- ✅ Quick operation

- ✅ Lower cost for large sizes (3″+)

- ✅ Good for high flow applications

Disadvantages:

- ❌ Some flow restriction even when open

- ❌ Not suitable for small residential pipes

- ❌ Requires more maintenance

Best applications:

- Large commercial/industrial lines

- Fire protection systems

- Irrigation main lines

- Municipal water systems

Cost: $100-500+ (depends on size)

Note: Rarely used in typical residential plumbing.

Types by Location and Function

Main Shut Off Valves

Purpose: Control all water entering your home.

Typical valve types:

- Ball valve (preferred, modern)

- Gate valve (older homes)

Common locations:

- Basement near front wall

- Utility/mechanical room

- Crawl space

- Outside at curb box

Size: Usually 3/4″ to 1″ diameter

For complete guide on main valves, see: Water Main Shut Off Valve: Location & How to Use

Fixture Shut Off Valves

Purpose: Control water to individual sinks, toilets, and tubs.

Typical valve types:

- Angle stop (most common)

- Straight stop

- Quarter-turn ball valve

Common locations:

- Under bathroom sinks (2 valves: hot and cold)

- Under kitchen sinks (2 valves)

- Behind toilets (1 valve: cold only)

- Behind washing machines (2 valves)

Size: Usually 1/2″ supply to 3/8″ outlet

Connection types:

- Compression (no soldering required)

- Sweat/solder

- Push-fit (SharkBite style)

- Threaded

Why important: Allows repair or replacement of individual fixtures without shutting off entire house.

Appliance Valves

Purpose: Control water to specific appliances.

Common appliances with shutoffs:

Water Heater:

- Cold inlet valve (always present)

- Sometimes hot outlet valve

- Usually ball or gate valve

- Size: 3/4″ typical

Washing Machine:

- Two valves (hot and cold)

- Often with hose thread connections

- Lever or knob style

- May have auto-shutoff feature

Dishwasher:

- Usually 3/8″ angle stop under sink

- Sometimes dedicated valve

- Hot water only

Refrigerator Ice Maker:

- Small saddle valve or angle stop

- 1/4″ or 3/8″ line

- Often under sink or in basement

Outdoor Valves

Hose Bibs (Outdoor Faucets):

Standard hose bib:

- Globe valve mechanism

- Usually has vacuum breaker

- 1/2″ or 3/4″ connection

- Freezes in winter

Frost-free hose bib:

- Valve seat inside heated space

- Long stem (6″-12″)

- Drains automatically

- Prevents freezing

Anti-siphon hose bib:

- Built-in backflow prevention

- Required by code in many areas

- Prevents contamination

Irrigation valves:

- Usually ball or gate valves

- Manual or automatic

- Multiple zones

Types by Material

Brass Valves

Characteristics:

- Gold/yellow color

- Heavy, solid feel

- Corrosion-resistant

- Standard for most applications

Advantages:

- ✅ Excellent durability (30+ years)

- ✅ Resists corrosion

- ✅ Handles hot water well

- ✅ Industry standard

Disadvantages:

- ❌ More expensive

- ❌ Can dezincify in certain water conditions

Best for: Main shutoffs, hot water lines, permanent installations

Cost: $20-60 for residential valves

Bronze Valves

Characteristics:

- Reddish-brown color

- Similar to brass but different alloy

- Very durable

- Often used in marine applications

Advantages:

- ✅ Superior corrosion resistance

- ✅ Excellent for saltwater/coastal areas

- ✅ Very long lifespan

- ✅ Handles pressure well

Disadvantages:

- ❌ Most expensive material

- ❌ Overkill for most residential use

Best for: Coastal homes, well water systems, high-quality installations

Cost: $30-80 for residential valves

Stainless Steel Valves

Characteristics:

- Silver/metallic appearance

- Extremely corrosion-resistant

- Modern aesthetic

- Premium material

Advantages:

- ✅ Will not corrode

- ✅ Ideal for harsh water

- ✅ Clean, modern look

- ✅ Food-grade safe

Disadvantages:

- ❌ Expensive

- ❌ Limited availability for residential

- ❌ May require special fittings

Best for: Harsh water conditions, visible installations, commercial kitchens

Cost: $40-100+

PVC/Plastic Valves

Characteristics:

- White or gray color

- Lightweight

- Usually threaded or solvent-welded

- Limited temperature range

Advantages:

- ✅ Lowest cost

- ✅ Never corrodes

- ✅ Easy to install (solvent weld or thread)

- ✅ Lightweight

Disadvantages:

- ❌ Not for hot water (usually)

- ❌ Can become brittle over time

- ❌ UV damage if exposed to sun

- ❌ Lower pressure rating

- ❌ Not code-compliant everywhere

Best for: Cold water only, irrigation, pool systems, temporary installations

Cost: $5-20

Important: PVC valves often not allowed for main house shutoffs. Check local codes.

Valve Comparison Table

| Valve Type | Operation | Reliability | Cost | Best For | Lifespan |

|---|---|---|---|---|---|

| Ball Valve | Quarter-turn | Excellent | $$ | Main shutoffs | 20-30 years |

| Gate Valve | Multi-turn | Good | $ | Large pipes | 20-30 years |

| Globe Valve | Multi-turn | Good | $$ | Flow control | 15-25 years |

| Angle Stop | Varies | Good | $ | Fixtures | 10-20 years |

| Butterfly | Quarter-turn | Good | $$-$$$ | Large commercial | 20-30 years |

Material Comparison:

| Material | Durability | Corrosion Resistance | Cost | Applications |

|---|---|---|---|---|

| Brass | Excellent | Excellent | $$ | Standard residential |

| Bronze | Excellent | Superior | $$$ | Coastal, marine |

| Stainless | Excellent | Superior | $$$-$$$$ | Harsh water |

| PVC | Good | Excellent | $ | Cold water, irrigation |

How to Choose the Right Valve

By Application

Main house shutoff: → Ball valve (brass or bronze)

- Quarter-turn operation

- Most reliable

- Clear on/off indicator

Individual fixtures (sinks, toilets): → Angle stop, quarter-turn

- Compact design

- Easy replacement

- Compression connection (no soldering)

Outdoor faucets: → Frost-free hose bib

- Prevents freezing

- Drains automatically

- Long-stem design

Flow control needs: → Globe valve

- Precise throttling

- Good modulation

- Where adjustment needed

By Water Conditions

Normal municipal water: → Brass valves

- Standard quality

- Good for most homes

- Proven performance

Coastal/saltwater areas: → Bronze valves

- Superior corrosion resistance

- Worth the extra cost

- Long-term reliability

Hard water/well water: → Stainless steel or brass

- Resists mineral buildup

- Easy to clean

- Long service life

Cold water only (irrigation): → PVC ball valves

- Cost-effective

- Corrosion-proof

- Easy to work with

By Budget

Budget-conscious ($):

- Gate valves for mains

- Multi-turn angle stops

- PVC for irrigation

- DIY installation

Standard quality ($$):

- Ball valves for mains

- Quarter-turn angle stops

- Brass construction

- Professional installation recommended

Premium ($$$):

- Ball valves throughout

- Bronze or stainless steel

- Quarter-turn angle stops

- Professional installation

By Replacement Priority

Replace immediately if:

- Valve won’t close completely

- Leaking at handle

- Over 25-30 years old

- Failed during use

Plan replacement if:

- 15-20 years old

- Shows corrosion

- Difficult to operate

- Upgrading plumbing

Can wait if:

- Less than 10 years old

- Operates smoothly

- No leaks

- Tested regularly

Installation Considerations

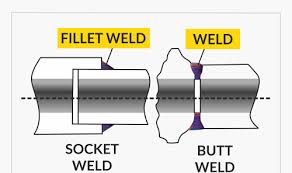

Connection Types

Compression Fittings:

- No soldering required

- Good for DIY

- Most common for angle stops

- Can be removed and reused

Sweat/Solder Connections:

- Permanent installation

- Requires torch

- Professional quality

- Most reliable long-term

Threaded Connections:

- Screw together

- Use pipe dope or Teflon tape

- Common for iron pipe

- Can leak if not sealed properly

Push-Fit (SharkBite):

- No tools required

- Push pipe into fitting

- More expensive

- Good for quick repairs

- Some codes restrict use

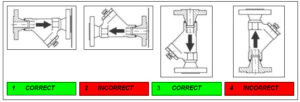

Valve Orientation

Ball and gate valves:

- Can be installed in any orientation

- Horizontal preferred for ease of operation

- Vertical okay

Globe valves:

- Arrow indicates flow direction

- Must be installed correctly

- Check manufacturer instructions

Angle stops:

- Always 90-degree orientation

- Input and output perpendicular

Code Requirements

Check local codes for:

- Approved valve types

- Material requirements

- Backflow prevention needs

- Inspection requirements

- Permit needs

Common code requirements:

- Ball valves required for new main shutoffs

- Earthquake shutoff valves (some areas)

- Vacuum breakers on hose bibs

- Accessible main shutoff location

Maintenance by Valve Type

Ball Valves

Maintenance:

- Exercise twice yearly (open/close)

- Usually maintenance-free

- Replace if handle breaks or leaks

Lifespan: 20-30 years

Gate Valves

Maintenance:

- Exercise twice yearly (important!)

- Apply lubricant to stem threads

- Watch for packing nut leaks

- Replace worn packing

Lifespan: 20-30 years (if maintained)

Angle Stops

Maintenance:

- Exercise annually

- Check for leaks at compression fittings

- Replace if corroded

Lifespan: 10-20 years (fixture use)

Common issue: Mineral buildup on stems

Common Problems and Solutions

Problem 1: Valve Won’t Turn

Most common in: Gate valves, old angle stops

Solutions:

- Apply penetrating oil, wait 15 minutes

- Use gentle back-and-forth motion

- Don’t force (can break)

- May need replacement

Problem 2: Valve Leaks at Handle

Most common in: Gate valves, globe valves

Quick fix:

- Tighten packing nut (under handle)

- May stop drip temporarily

Permanent fix:

- Replace packing

- Or replace valve

Problem 3: Valve Won’t Close Completely

Most common in: Old gate valves

Cause:

- Corroded internal parts

- Gate damaged or stuck

Solution:

- Replacement required

- Cannot be repaired effectively

Problem 4: Compression Fitting Leaks

Most common in: Angle stops

Solutions:

- Tighten compression nut (1/4 turn at a time)

- If still leaks, turn off water and remake connection

- May need new ferrule

Upgrading Your Valves

When to Upgrade

Good reasons to upgrade:

- Replacing old gate valves with ball valves

- Upgrading multi-turn angle stops to quarter-turn

- Adding individual fixture shutoffs

- Improving accessibility

Benefits:

- Faster operation in emergencies

- More reliable performance

- Visual on/off indication

- Easier for anyone to operate

DIY vs Professional Installation

Good DIY projects:

- Replacing angle stops (if experienced)

- Installing outdoor hose bibs

- Adding fixture shutoffs

Hire a professional for:

- Main water shut off replacement (requires street shutoff)

- Soldered connections (if not experienced)

- Large valve installations

- Code-required work

Typical professional costs:

- Main valve replacement: $200-500

- Angle stop replacement: $100-150 each

- Outdoor hose bib: $150-300

Frequently Asked Questions

What’s the best type of shut off valve?

Ball valves are the best overall choice for reliability and ease of use. They offer quarter-turn operation, visual on/off indication, and rarely fail even after years of non-use. For main shutoffs and critical applications, ball valves are strongly recommended over gate valves.

Can I replace a gate valve with a ball valve?

Yes, and this is a common upgrade. Ball valves are more reliable and easier to operate. However, replacing a main shutoff valve requires turning off water at the street, so professional installation is recommended. Cost typically ranges from $200-500.

How long do water shut off valves last?

Ball valves and gate valves typically last 20-30 years. Fixture angle stops last 10-20 years. Lifespan depends on water quality, frequency of use, and whether the valve is exercised regularly. Brass and bronze valves last longer than plastic ones.

What’s the difference between brass and bronze valves?

Brass is a copper-zinc alloy (yellowish), while bronze is copper-tin (reddish-brown). Bronze has superior corrosion resistance and is preferred for marine/coastal applications and well water systems. Brass is standard for most residential plumbing and costs less.

Why do angle stops fail so often?

Angle stops are frequently operated during repairs and replacements, leading to more wear. They’re also exposed to mineral buildup from water. Many older angle stops are multi-turn gate-style, which are less reliable than modern quarter-turn ball-style angle stops.

Can I use PVC valves for my main shut off?

Generally no. Most building codes require metal valves (brass, bronze, or stainless steel) for main shutoffs due to pressure ratings, durability, and fire safety. PVC valves are typically limited to cold water applications like irrigation and may not be rated for the pressure of main water lines.

Do I need special tools to install shut off valves?

For compression-fitting angle stops, you need basic wrenches and possibly a tubing cutter. For soldered connections, you need a torch and soldering skills. Push-fit valves require no special tools but cost more. Main valve replacement requires professional equipment to access the street shutoff.

Should I replace all my valves at once?

Not necessarily. Replace valves based on age, condition, and priority:

- Immediate: Main shutoff if over 30 years old or not working

- High priority: Fixture valves that leak or won’t close

- Lower priority: Working valves under 15 years old

Upgrading during renovations is cost-effective since walls are already open.

Conclusion

Understanding water shut off valve types helps you make informed decisions about repairs, replacements, and upgrades. The right valve depends on your specific application, water conditions, and budget.

Key recommendations:

For main shutoffs:

- ✅ Choose ball valves (brass or bronze)

- ✅ Quarter-turn operation is essential

- ✅ Test twice yearly

- ✅ Replace gate valves when upgrading

For fixtures:

- ✅ Use quarter-turn angle stops

- ✅ Compression fittings for easy replacement

- ✅ Install individual shutoffs for all fixtures

- ✅ Replace if over 15 years old

For outdoor:

- ✅ Install frost-free hose bibs in cold climates

- ✅ Add anti-siphon feature

- ✅ Drain before winter

General tips:

- Exercise all valves twice yearly

- Replace proactively (don’t wait for failure)

- Upgrade to ball valves when replacing

- Keep valve locations documented

- Have a plumber’s number ready

Investing in quality shut off valves and maintaining them properly provides peace of mind and can prevent thousands of dollars in water damage during emergencies.