Table of Contents

ToggleQuick Answer

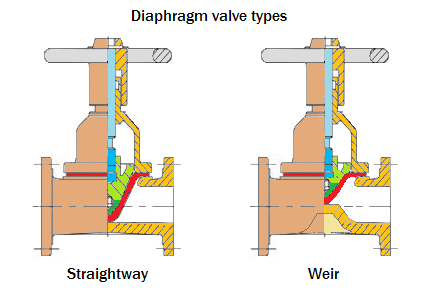

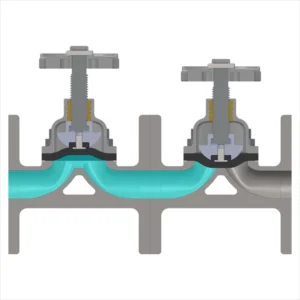

There are two main types of diaphragm valves: weir-type (saddle) and straight-through (full-bore). Weir-type valves have a raised saddle that the diaphragm seals against, ideal for throttling and clean fluids. Straight-through valves have a flat bottom with unobstructed flow, best for slurries and viscous media. Both isolate the media from moving parts, making them excellent for corrosive, abrasive, or sterile applications.

Key difference: Weir-type = precision control + less diaphragm wear. Straight-through = full flow + handles solids better.

Understanding Diaphragm Valves

What Makes Them Unique

A diaphragm valve (or membrane valve) consists of a valve body with two or more ports, a flexible diaphragm, and a weir or saddle (or seat) upon which the diaphragm closes the valve.

Three main components:

- Valve Body – Metal, plastic, or lined

- Flexible Diaphragm – Rubber or elastomer membrane

- Compressor – Pushes diaphragm down to close

The key advantage: The diaphragm isolates all moving parts from the media. Only the diaphragm and valve body contact the fluid, preventing contamination and protecting the mechanism from corrosion.

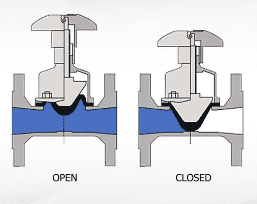

How Diaphragm Valves Work

Opening:

- Handwheel turns (or actuator operates)

- Stem lifts compressor upward

- Diaphragm lifts off seat/weir

- Fluid flows freely

Closing:

- Stem pushes compressor downward

- Compressor presses diaphragm against seat/weir

- Creates leak-tight seal

- Flow stops completely

Why the diaphragm matters: The diaphragm acts as both the sealing element AND the gasket between body and bonnet. This eliminates the need for packing glands or stem seals that can leak.

The Two Main Types

1. Weir-Type Diaphragm Valves

Design characteristics:

The weir-type diaphragm valve features a raised lip or “weir” saddle where the diaphragm makes contact to form a positive seal. This unique valve body design significantly reduces the travel distance of the diaphragm from fully open to fully closed.

Structure:

┌──────────────────┐

│ Bonnet/Stem │

│ ↓ │

│ [Compressor] │

│ ↓ │

│ ╱¯¯Diaphragm¯¯╲ │

│╱ ▲▲▲ ╲│ ← Raised weir/saddle

│ Flow ══→ │

└──────────────────┘

How it works: In the closed position, the diaphragm presses tightly against the weir, creating a leak-proof seal. When opened, the diaphragm lifts, forming a flow path over the weir.

Advantages:

- ✅ Less diaphragm movement (reduced stress)

- ✅ Longer diaphragm life

- ✅ Excellent for throttling and flow control

- ✅ Better at throttling than straight-through because the design’s large shutoff area gives it quick-opening valve characteristics

- ✅ Can use thicker diaphragm materials

- ✅ Suitable for high pressure and vacuum

- ✅ Self-draining design

- ✅ Precise control at low flow rates

Disadvantages:

- ❌ Higher pressure drop than straight-through

- ❌ Can collect sediment on weir

- ❌ Not ideal for thick slurries or high-solid content

Best for:

- Ideal for managing gases, clean liquid media, high-purity water, and other homogeneous fluids

- Throttling applications

- Clean fluids

- Corrosive chemicals

- Sterile/aseptic processing

- Food and pharmaceutical

2. Straight-Through (Full-Bore) Diaphragm Valves

Design characteristics:

Straight-through diaphragm valves, also known as full-bore or straightway diaphragm valves, feature a streamlined, flat-bottomed valve body to minimize flow resistance and pressure drop.

Structure:

┌──────────────────┐

│ Bonnet/Stem │

│ ↓ │

│ [Compressor] │

│ ↓ │

│ ╱¯¯Diaphragm¯¯╲ │

│╱ ╲│ ← Flat bottom (no obstruction)

│ Flow ═════→ │

└──────────────────┘

How it works: The diaphragm must stretch further to seal against the flat bottom of the valve body. This requires a more flexible diaphragm material.

Advantages:

- ✅ Full bore, unobstructed flow

- ✅ Minimal pressure drop

- ✅ Handles slurries and viscous fluids

- ✅ Excellent for solids-laden media

- ✅ Easy to clean (no dead spaces)

- ✅ Bidirectional flow capable

- ✅ Fast open/close applications

Disadvantages:

- ❌ More diaphragm flexing (shorter life)

- ❌ Requires more flexible diaphragm material

- ❌ Less precise throttling control

- ❌ More frequent diaphragm replacement

Best for:

- The straight flow path allows fluids—especially slurries, viscous liquids, suspensions, and semi-solid media—to move uninterrupted

- On/off service

- Slurries and sludges

- Viscous materials

- Media with suspended solids

- High flow rate applications

- Applications prone to clogging

Weir vs Straight-Through: Direct Comparison

Comparison Table

| Feature | Weir-Type | Straight-Through |

|---|---|---|

| Flow path | Over raised saddle | Straight, unobstructed |

| Pressure drop | Moderate | Minimal |

| Diaphragm travel | Short | Long |

| Diaphragm life | Longer | Shorter |

| Throttling | Excellent | Fair |

| On/off service | Good | Excellent |

| Slurry handling | Fair | Excellent |

| Clean fluids | Excellent | Good |

| Maintenance | Less frequent | More frequent |

| Self-draining | Yes | Limited |

| Cost | Higher | Lower |

When to Choose Weir-Type

Choose weir-type for:

- Precise flow control and throttling

- Clean, homogeneous fluids

- Corrosive chemicals

- Sterile applications (food, pharma)

- High-purity water systems

- Applications requiring minimal dead space

- Longer diaphragm service life priority

Example applications:

- Pharmaceutical batch processes

- Food and beverage CIP systems

- Ultrapure water systems

- Chemical dosing

- Laboratory applications

When to Choose Straight-Through

Choose straight-through for:

- Slurries with suspended solids

- Viscous materials

- Semi-solid media

- High flow rate requirements

- On/off service (not throttling)

- Applications prone to clogging

- Bidirectional flow needs

Example applications:

- Mining slurries

- Wastewater sludge

- Pulp and paper stock

- Food purees and sauces

- Adhesives and resins

- Cement and concrete

Other Classifications of Diaphragm Valves

By Port Configuration

2/2-Way (Two-Port):

- While diaphragm valves usually come in two-port forms (2/2-way diaphragm valve), they can also come with three ports (3/2-way diaphragm valves also called T-valves) and more (so called block-valves)

- Standard inlet and outlet

- Most common configuration

- Simple flow control

3/2-Way (Three-Port T-Valve):

- One inlet, two outlets (or vice versa)

- Flow diversion or mixing

- Can direct flow to different paths

Block Valves (Multi-Port):

- Multiple ports (4+)

- Complex flow routing

- May require multiple diaphragm seats

By Actuation Method

Manual:

- Handwheel operated

- No external power needed

- Operator presence required

- Suitable for infrequent operation

Pneumatic:

- The most common diaphragm valves use pneumatic actuators; in this type of valve, air pressure is applied through a pilot valve into the actuator which in turn raises the diaphragm and opens the valve

- Fast actuation (1-3 seconds typical)

- Remote operation possible

- Requires compressed air supply

- Can integrate with control systems

Hydraulic:

- Higher force capability

- Slower actuation than pneumatic

- Used for very large valves or high pressures

Electric:

- Motor-driven actuator

- Precise positioning

- No air supply needed

- Programmable control

By Application Type

Sanitary/Hygienic: Sanitary diaphragm valves are used in industries like food, beverages and pharmaceuticals, where keeping fluids clean and free of contamination is essential. These valves maintain a sterile environment to prevent the growth of bacteria or fungi.

Features:

- Polished internal surfaces

- Self-draining design

- FDA/USP compliant materials

- CIP/SIP compatible

- Crevice-free construction

Biotech: Biotech valves are designed for handling fluids with microorganisms or biological materials. They are commonly used in processes like bioreactors, fermenters, filtration systems and freeze-thaw applications.

Features:

- Sterile operation

- Compatible with steam sterilization

- Single-use options available

- Validation documentation provided

Industrial:

- Heavy-duty construction

- Abrasion-resistant linings

- Wide range of body materials

- Handles harsh chemicals

Body and Diaphragm Materials

Body Materials

Typical materials for the diaphragm valve body are PVC, stainless steel, brass, bronze, and cast iron. The material should withstand the environment and media flowing through the valve.

Material selection guide:

PVC (Polyvinyl Chloride):

- Lightweight and economical

- Good chemical resistance

- Temperature limit: 140°F

- Not for high pressure

PP (Polypropylene):

- Better chemical resistance than PVC

- Higher temperature tolerance

- Lightweight

- Cost-effective

PVDF (Polyvinylidene Fluoride):

- Excellent chemical resistance

- High temperature capability (280°F)

- More expensive

- Ultrapure applications

Stainless Steel (316, 316L):

- For example, stainless steel is commonly chosen for applications requiring sterile conditions (e.g., food and beverage)

- Excellent corrosion resistance

- High strength

- Sanitary finishes available

- Premium cost

Cast Iron:

- Economical

- Good strength

- Heavier weight

- Typically lined for corrosion protection

Lined Bodies:

- Metal body with PTFE, rubber, or plastic lining

- Combines strength with chemical resistance

- Common in chemical processing

Diaphragm Materials

The diaphragm’s material is flexible so that the valve can operate correctly. Commonly used materials are EPDM, PTFE, butyl rubber, and nitrile rubber.

Material guide:

EPDM (Ethylene Propylene):

- Temperature: -40°F to 250°F

- Excellent steam and water resistance

- Good chemical resistance (acids, alkalis)

- Not for oils or hydrocarbons

PTFE (Teflon):

- Temperature: -100°F to 400°F

- Outstanding chemical resistance

- Nearly universal compatibility

- Higher cost

- Can be lined or solid

Nitrile (NBR/Buna-N):

- Temperature: -40°F to 180°F

- Excellent oil resistance

- Good abrasion resistance

- Not for strong acids

Butyl Rubber:

- Temperature: -40°F to 250°F

- Excellent gas impermeability

- Good chemical resistance

- Lower cost

Natural Rubber:

- Temperature: -40°F to 180°F

- Good elasticity

- Not for oils or chemicals

- Economical

Silicone:

- Temperature: -60°F to 400°F

- Food grade available

- Poor abrasion resistance

- Flexible at low temps

Key Advantages of Diaphragm Valves

1. Leak-Tight Sealing

Diaphragm Valve is designed for leak-proof control of abrasive and corrosive liquids, suspensions, slurries, and pulps.

Why it matters:

- Diaphragm acts as barrier and seal

- No stem packing to leak

- Zero fugitive emissions

- Ideal for hazardous materials

2. No Contamination

Diaphragm valves provide an external seal, therefore all moving parts are fully isolated from the wetted parts and the media being conveyed.

Benefits:

- Only diaphragm and body contact media

- No metal-to-metal contact in flow path

- No lubrication in process stream

- Critical for food, pharma, biotech

3. Handles Difficult Media

Excellent for:

- Corrosive chemicals (acids, alkalis)

- Abrasive slurries

- Viscous fluids

- Suspended solids

- Fibrous materials

4. Low Maintenance

The moving parts of a diaphragm valve are isolated from the media being conveyed resulting in durability and isolation.

Why less maintenance:

- No packing glands to adjust

- No stem seals to replace

- Diaphragm only wearing part

- Simple replacement procedure

5. Sanitary Design

Diaphragm valves offer crevice-free surfaces and full isolation of internal parts, preventing microbial buildup. They support clean-in-place (CIP) or sterilization, meet FDA or USP standards, and ensure product purity and regulatory compliance.

Installation and Sizing Considerations

Connection Types

Connection types include threaded, compression fittings, bolt flange, clamp flange, tube fitting, butt weld, socket weld, and metal face seal.

Common options:

Flanged:

- Most common for industrial

- ANSI, DIN, or JIS standards

- Easy maintenance access

Threaded:

- Smaller sizes (≤2″)

- NPT or BSP threads

- Simple installation

Clamp (Tri-Clamp/TC):

- Sanitary applications

- Quick disconnect

- Easy cleaning

Butt Weld:

- Permanent installation

- High integrity

- Process piping

Sizing Guidelines

For on/off service:

- Match valve size to pipe size

- No significant restriction

- Straightforward selection

For throttling:

- Calculate Cv (flow coefficient) required

- Consider pressure drop

- Weir-type better for throttling applications

Factors affecting size:

- Flow rate requirements

- Pressure drop limitations

- Pipe size

- Media characteristics

- Control requirements

Standards Compliance

Many diaphragm valve body dimensions follow the Manufacturers Standardization Society MSS SP-88. However, most non-diaphragm valves used in industrial applications are built to the ANSI/ASME B16.10 standard.

Available standards:

- MSS SP-88: Traditional diaphragm valve standard

- ANSI B16.10: Face-to-face dimensions (some manufacturers)

- Allows interchangeability with other valve types

Maintenance and Troubleshooting

Diaphragm Replacement

When to replace:

- Visible cracks or damage

- Leaking between body and bonnet

- Loss of sealing effectiveness

- Recommended service intervals reached

Replacement procedure:

- Close and isolate valve

- Remove bonnet bolts

- Lift off bonnet assembly

- Remove old diaphragm

- Clean mating surfaces

- Install new diaphragm

- Replace bonnet

- Torque bolts properly

Typical service life:

- Clean water: 5-10 years

- Chemicals: 2-5 years

- Abrasive slurries: 6 months – 2 years

- Depends on cycles, temperature, media

Common Problems

Leaking from bonnet:

- Worn diaphragm

- Loose bonnet bolts

- Damaged mating surfaces

- Solution: Replace diaphragm, re-torque bolts

Poor throttling control:

- Worn diaphragm (stretched)

- Wrong valve type for application

- Solution: Replace diaphragm, verify valve selection

Won’t close completely:

- Foreign material on seat

- Damaged diaphragm

- Bent compressor

- Solution: Clean, inspect, replace parts

Excessive pressure drop:

- Wrong valve type (weir vs straight-through)

- Undersized valve

- Partially closed

- Solution: Verify valve fully open, check sizing

Comparison with Other Valve Types

Diaphragm Valve vs Ball Valve

Diaphragm advantages:

- ✅ Better for corrosive media

- ✅ No contamination

- ✅ Handles slurries better

- ✅ Sanitary design

Ball Valve advantages:

- ✅ Higher pressure ratings

- ✅ More compact

- ✅ Lower cost

- ✅ Faster actuation

Diaphragm Valve vs Pinch Valve

Diaphragm advantages:

- ✅ Better throttling control

- ✅ Higher pressure capability

- ✅ More body material options

- ✅ Self-draining (weir type)

Pinch Valve advantages:

- ✅ Full bore always

- ✅ Better for heavy abrasives

- ✅ Simpler design

- ✅ Lower cost

Diaphragm Valve vs Butterfly Valve

Diaphragm advantages:

- ✅ Zero contamination

- ✅ Better for corrosives

- ✅ Leak-tight seal

- ✅ Sanitary applications

Butterfly Valve advantages:

- ✅ Much lower cost

- ✅ More compact

- ✅ Lighter weight

- ✅ Larger sizes available

Applications by Industry

Food and Beverage

Why diaphragm valves excel:

- FDA-compliant materials

- Sanitary design

- CIP/SIP compatible

- No contamination

Applications:

- Dairy processing

- Brewing and wine

- Juice production

- Sauces and condiments

- Bottling lines

Pharmaceutical and Biotech

Critical requirements:

- Sterile operation

- Validation documentation

- USP Class VI materials

- Cleanable design

Applications:

- API production

- Sterile filling

- Fermentation

- Buffer preparation

- WFI systems

Chemical Processing

Why diaphragm valves work:

- Corrosion resistance

- Wide material options

- Handles hazardous materials

Applications:

- Acid/alkali handling

- Solvent systems

- Catalyst preparation

- Batch processing

- Chemical transfer

Water and Wastewater

Applications:

- Ultrapure water systems

- RO/DI systems

- Chemical dosing

- Sludge handling

- pH adjustment

Pulp and Paper

Applications:

- Stock control

- Bleach plant

- Chemical additives

- White water systems

Frequently Asked Questions

What is the main difference between weir and straight-through diaphragm valves?

Weir-type valves have a raised saddle that reduces diaphragm travel and provides better throttling control, ideal for clean fluids. Straight-through valves have a flat bottom with unobstructed flow, better for slurries and viscous media. Weir-type offers longer diaphragm life, while straight-through provides minimal pressure drop.

How long do diaphragm valve diaphragms last?

Diaphragm life depends on application conditions. In clean water service, expect 5-10 years. In chemical service, 2-5 years is typical. For abrasive slurries, replacement may be needed every 6 months to 2 years. Factors include operating cycles, temperature, media compatibility, and valve type.

Can diaphragm valves be used for steam?

Yes, with proper materials. The diaphragm must be rated for steam temperature (typically EPDM or PTFE). Weir-type valves work better for steam than straight-through due to self-draining design. Verify manufacturer ratings for specific steam conditions.

Are diaphragm valves suitable for high pressure?

Weir-type diaphragm valves can handle moderate to high pressures (up to 150-300 PSI depending on design) better than straight-through types. The weir design allows thicker diaphragm materials. For very high pressures (>300 PSI), consider ball or gate valves instead.

Can diaphragm valves handle abrasive slurries?

Yes, especially straight-through types with their unobstructed flow path. Choose abrasion-resistant diaphragm materials (like natural rubber) and lined or plastic bodies. Weir-type valves can handle moderate abrasives but may experience sediment buildup on the saddle.

How do I select diaphragm material?

Consider three factors: chemical compatibility with your media, operating temperature range, and physical properties needed (abrasion resistance, flexibility). For acids/alkalis use EPDM or PTFE. For oils use Nitrile. For food use FDA-approved silicone or EPDM. Consult chemical compatibility charts.

Are diaphragm valves bidirectional?

Straight-through diaphragm valves work equally well in both flow directions. Weir-type valves can technically handle bidirectional flow but the weir design may affect performance. Check manufacturer specifications. In most installations, flow direction should still be marked for consistency.

Can diaphragm valves be automated?

Yes, diaphragm valves are easily automated with pneumatic, hydraulic, or electric actuators. Pneumatic is most common. They integrate well with control systems using positioners, limit switches, and solenoid valves. Response time is typically 1-5 seconds depending on valve size and actuator type.

Conclusion

Diaphragm valves offer unique advantages for controlling difficult and corrosive media while maintaining zero contamination. Understanding the difference between weir-type and straight-through designs is essential to selecting the right valve for your application.

Key takeaways:

Weir-Type Diaphragm Valves:

- ✅ Best for: Throttling, clean fluids, sterile applications

- ✅ Advantages: Longer diaphragm life, precise control, self-draining

- ✅ Ideal industries: Food, pharma, biotech, chemicals

Straight-Through Diaphragm Valves:

- ✅ Best for: Slurries, viscous fluids, on/off service

- ✅ Advantages: Full bore flow, minimal pressure drop, handles solids

- ✅ Ideal industries: Mining, wastewater, pulp and paper

Overall advantages of diaphragm valves:

- Zero fugitive emissions

- No contamination

- Handles corrosive and abrasive media

- Sanitary design

- Low maintenance

- Leak-tight sealing

Selection criteria:

- Media type (clean vs. slurry)

- Application (throttling vs. on/off)

- Sanitary requirements

- Pressure and temperature

- Diaphragm life priority

- Budget

When choosing between diaphragm valve types, match the design to your specific process needs. For precision control of clean, corrosive, or sterile fluids, choose weir-type. For full-bore flow of slurries and viscous media, choose straight-through. Both offer the contamination-free operation that makes diaphragm valves essential in modern process industries.