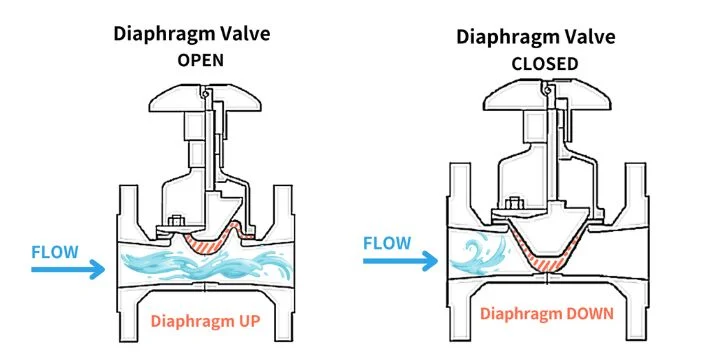

A diaphragm valve is a flow-control device that uses a flexible diaphragm to regulate, start, or stop the flow of fluids. When the diaphragm is pressed down onto a seat, the flow is blocked; when lifted, fluid can pass through. This simple yet effective mechanism makes diaphragm valves ideal for corrosive, viscous, abrasive, or sterile applications.

Diaphragm valves are widely used in industries such as water treatment, pharmaceuticals, chemical processing, food & beverage, and semiconductors.

Table of Contents

ToggleHow a Diaphragm Valve Works

A diaphragm valve has three main parts:

Body – Contains the fluid passage.

Diaphragm – A flexible membrane made of rubber or polymer (EPDM, PTFE, Viton, etc.).

Actuator/Bonnet – Applies force to open or close the diaphragm.

Operation principle:

Closing: The actuator pushes the diaphragm down onto a weir (raised seat) or straight seat, sealing the flow.

Opening: The actuator lifts the diaphragm, allowing fluid to pass.

Because the fluid never contacts the actuator or upper valve body, diaphragm valves provide excellent leak-tight isolation and clean operation.

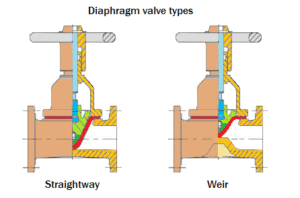

Types of Diaphragm Valves

1. Weir-Type (Saddle-Type)

Most common design

Ideal for general flow control

Suitable for corrosive and dirty fluids

Reduced dead space helps prevent contamination

2. Straight-Through (Full-Bore) Diaphragm Valve

No weir; full opening for high flow rates

Best for slurries, viscous materials, and media with suspended solids

3. Manual Diaphragm Valves

Operated by handwheel

Used in low-pressure or small system applications

4. Actuated Diaphragm Valves

Can be operated by:

Pneumatic actuators

Electric actuators

Hydraulic actuators

Common in automated industrial processes.

Advantages of Diaphragm Valves

Excellent shutoff capability

Leak-proof design

Suitable for corrosive and abrasive fluids

No fluid contamination (fluid isolated from moving parts)

Easy maintenance

Smooth flow control

Ideal for sanitary applications (pharma, food, biotech)

Disadvantages of Diaphragm Valves

Limited pressure and temperature rating (due to diaphragm material)

Diaphragm eventually wears and needs replacement

Not suitable for very high-flow or high-pressure systems

Not ideal for throttling extremely viscous fluids

Common Applications

1. Water Treatment & Distribution

Used for chemical dosing, wastewater control, and desalination.

2. Pharmaceutical & Biotech

Perfect for sanitary processes due to smooth internal surfaces and clean sealing.

3. Food & Beverage

Prevents contamination and supports clean-in-place (CIP) systems.

4. Chemical Processing

Handles acids, alkalis, corrosive slurries, and solvents.

5. Semiconductor Manufacturing

Used for ultra-pure water (UPW) and chemical transport.

Diaphragm Valve vs. Ball Valve

| Feature | Diaphragm Valve | Ball Valve |

|---|---|---|

| Flow Control | Excellent for throttling | Poor throttling, best for on/off |

| Cleanliness | Superior; no cavities | Has dead space |

| Media Compatibility | Corrosive, abrasive, sterile | General fluids |

| Maintenance | Easy | Moderate |

| Pressure Rating | Lower | Higher |

Conclusion

A diaphragm valve is a versatile, reliable, and sanitary flow-control device that excels in applications requiring clean, leak-tight, and corrosion-resistant operation. With weir-type and straight-through designs, diaphragm valves are well-suited for industries where fluid purity and precise control are critical.