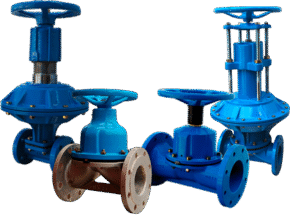

A membrane valve—also commonly called a diaphragm valve—is a flow-control device that uses a flexible membrane (or diaphragm) to open, close, or regulate fluid flow. The membrane is typically made of elastomer or polymer materials such as EPDM, PTFE, silicone, or Viton.

Membrane valves are widely used in applications requiring clean, sterile, or corrosion-resistant fluid handling, such as pharmaceutical manufacturing, food processing, water treatment, biotechnology, and chemical dosing.

Table of Contents

ToggleHow a Membrane Valve Works

A membrane valve consists of three main components:

Valve Body – Contains the fluid passage.

Membrane (Diaphragm) – A flexible sheet that forms the sealing surface.

Actuator or Handwheel – Applies force to move the membrane.

Operation Principle

Valve Closed:

The actuator pushes the membrane down onto a seat (or weir), sealing off the flow path.Valve Open:

The membrane is lifted, allowing fluid to pass through the body.

Because the fluid only contacts the valve body and the membrane, the valve provides clean operation, zero leakage to the atmosphere, and excellent corrosion resistance.

Types of Membrane Valves

1. Weir-Type Membrane Valve

Has a raised weir or saddle inside the body.

Most common type.

Ideal for throttling and sanitary applications.

2. Straight-Through (Full-Bore) Membrane Valve

No weir; membrane closes directly on a flat seat.

Best for viscous fluids, slurries, and liquids containing solids.

3. Manual Membrane Valves

Operated by a handwheel.

Simple and cost-effective.

4. Actuated Membrane Valves

For automation, actuators can be:

Pneumatic

Electric

Hydraulic

Used in high-volume industrial processes.

Advantages of Membrane Valves

No contamination – Fluid is isolated from mechanical parts.

Excellent shutoff performance – Very reliable sealing.

Chemical resistance – Membranes and bodies can handle corrosive media.

Cleanability – Ideal for CIP/SIP systems in sanitary industries.

Low maintenance – Few moving parts inside the fluid path.

Good throttling capability – Especially in weir-type designs.

Disadvantages of Membrane Valves

Lower pressure/temperature limits compared to metal-seated valves.

Membrane wears over time and must be replaced periodically.

Not suitable for extremely high-pressure systems.

Throttling accuracy is lower than globe valves for fine control.

Common Applications

1. Pharmaceutical & Biotech

Sterile fluid transfer

Drug production

Clean-in-place (CIP) and steam-in-place (SIP) systems

2. Food & Beverage Processing

Brewing, dairy, beverage manufacturing

Sanitary piping systems

3. Water & Wastewater Treatment

Chemical injection

Corrosive fluid handling

4. Chemical Processing

Acids, alkalis, slurries, abrasive media

5. Semiconductor Manufacturing

Ultra-pure water (UPW)

High-purity chemical distribution

Membrane Valve vs. Diaphragm Valve

These two terms often mean the same thing.

In most industries, “membrane valve” = “diaphragm valve.”

However, some manufacturers use membrane valve to highlight:

The flexible sealing element (membrane)

Its role in ultra-clean or sanitary processes

Functionally, they are identical devices.

Conclusion

A membrane valve is a highly reliable, clean, and versatile flow-control valve that uses a flexible membrane to regulate fluid. Its leak-tight sealing and contamination-free operation make it essential in sanitary, corrosive, and high-purity applications.