Table of Contents

ToggleWhat is Valve Flow Coefficient (Cv)?

The valve flow coefficient, commonly known as Cv, is the most important parameter for valve sizing and selection. The Cv value represents the number of gallons per minute (GPM) of water at 60°F that will flow through a valve with a 1 psi pressure drop across it. This standardized measurement allows engineers to compare different valves and calculate the required valve size for any application.

Understanding the valve flow coefficient formula and how to apply it correctly is essential for system designers, plant engineers, and maintenance professionals to ensure optimal valve performance and avoid costly sizing errors.

The Essential Valve Flow Coefficient Formulas

Basic Cv Formula for Liquids

The fundamental valve flow coefficient formula for liquid applications is:

Cv = Q × √(SG / ΔP)

Where:

- Cv = Flow coefficient (dimensionless)

- Q = Flow rate in gallons per minute (GPM)

- SG = Specific gravity of the liquid (water = 1.0)

- ΔP = Pressure drop across the valve in psi

This formula is the foundation for all liquid valve sizing calculations and should be memorized by anyone working with valve selection.

Rearranging the Formula

You can rearrange the valve flow coefficient formula to solve for different variables:

To find flow rate: Q = Cv × √(ΔP / SG)

To find pressure drop: ΔP = (Q / Cv)² × SG

To find specific gravity: SG = ΔP × (Cv / Q)²

Cv Formula for Gas Flow

For gas and vapor applications, the valve flow coefficient formula becomes:

Cv = Q / (1360 × √(ΔP × P₁ / (SG × T)))

Or simplified:

Cv = Q × √((SG × T) / (1360 × ΔP × P₁))

Where:

- Q = Flow rate in standard cubic feet per hour (SCFH)

- SG = Gas specific gravity (air = 1.0)

- T = Absolute temperature in Rankine (°R = °F + 460)

- P₁ = Inlet absolute pressure in psia

- ΔP = Pressure drop in psi

Cv Formula for Steam

Steam requires a specialized valve flow coefficient formula:

Cv = W / (2.1 × P₁ × √(1 + ΔP/P₁))

Where:

- W = Steam mass flow rate in lb/hr

- P₁ = Inlet absolute pressure in psia

- ΔP = Pressure drop in psi

For saturated steam, you can also use:

Cv = W / (3 × P₁) (approximate formula when ΔP is small)

How to Calculate Valve Cv: Step-by-Step Examples

Example 1: Water Application (Basic Calculation)

Given data:

- Flow rate: 100 GPM

- Fluid: Water (SG = 1.0)

- Allowable pressure drop: 10 psi

Calculation:

Cv = Q × √(SG / ΔP)

Cv = 100 × √(1.0 / 10)

Cv = 100 × √0.1

Cv = 100 × 0.316

Cv = 31.6

Result: Select a valve with Cv ≥ 32

Example 2: Chemical Application

Given data:

- Flow rate: 75 GPM

- Fluid: Sulfuric acid solution (SG = 1.4)

- Allowable pressure drop: 8 psi

Calculation:

Cv = 75 × √(1.4 / 8)

Cv = 75 × √0.175

Cv = 75 × 0.418

Cv = 31.35

Result: Select a valve with Cv ≥ 32

Example 3: Viscous Fluid Calculation

Given data:

- Flow rate: 50 GPM

- Fluid: Hydraulic oil (SG = 0.9, viscosity = 150 cSt)

- Allowable pressure drop: 15 psi

Step 1 – Calculate base Cv:

Cv_base = 50 × √(0.9 / 15)

Cv_base = 50 × 0.245

Cv_base = 12.25

Step 2 – Apply viscosity correction (assume factor = 1.8 for this viscosity):

Cv_actual = 12.25 × 1.8

Cv_actual = 22.05

Result: Select a valve with Cv ≥ 22

Example 4: Gas Flow Calculation

Given data:

- Flow rate: 5000 SCFH of natural gas

- Gas specific gravity: 0.6

- Inlet pressure: 100 psia

- Temperature: 70°F (530°R)

- Pressure drop: 5 psi

Calculation:

Cv = Q × √((SG × T) / (1360 × ΔP × P₁))

Cv = 5000 × √((0.6 × 530) / (1360 × 5 × 100))

Cv = 5000 × √(318 / 680000)

Cv = 5000 × √0.000468

Cv = 5000 × 0.0216

Cv = 108

Result: Select a valve with Cv ≥ 110

Complete Valve Flow Coefficient Formula Reference Table

| Application | Formula | Units |

|---|---|---|

| Liquid Flow | Cv = Q × √(SG / ΔP) | Q in GPM |

| Gas Flow | Cv = Q × √((SG × T) / (1360 × ΔP × P₁)) | Q in SCFH |

| Steam Flow | Cv = W / (2.1 × P₁ × √(1 + ΔP/P₁)) | W in lb/hr |

| Find Flow Rate | Q = Cv × √(ΔP / SG) | Returns GPM |

| Find Pressure Drop | ΔP = (Q / Cv)² × SG | Returns psi |

| Cv to Kv Conversion | Kv = 0.865 × Cv | Metric units |

| Kv to Cv Conversion | Cv = 1.156 × Kv | Imperial units |

Critical Factors Affecting Cv Calculations

1. Specific Gravity Considerations

Specific gravity directly affects the valve flow coefficient calculation. Common fluids:

- Water: SG = 1.0

- Gasoline: SG = 0.72

- Diesel fuel: SG = 0.85

- Glycerin: SG = 1.26

- Sulfuric acid (98%): SG = 1.84

- Seawater: SG = 1.025

Always verify the specific gravity at operating temperature, as it changes with temperature.

2. Viscosity Impact

The standard valve flow coefficient formula assumes water-like viscosity (around 1 centipoises). For fluids with viscosity above 20 centipoises, you must apply a viscosity correction factor:

- 20-100 cSt: Multiply Cv by 1.2-1.5

- 100-500 cSt: Multiply Cv by 1.5-2.5

- 500+ cSt: Multiply Cv by 2.5-4.0 or more

Consult manufacturer viscosity correction charts for precise factors based on Reynolds number.

3. Choked Flow Conditions

When pressure drop becomes too large, flow reaches a maximum velocity and becomes “choked.” For liquids, choked flow occurs when:

ΔP > 0.5 × (P₁ – Pv)

Where Pv is the vapor pressure. When choked flow exists, use modified formulas provided by valve manufacturers, as the standard Cv formula no longer applies.

4. Temperature Effects

Temperature affects fluid properties:

- Density: Higher temperature = lower density = lower specific gravity

- Viscosity: Higher temperature = lower viscosity (for most liquids)

- Vapor pressure: Higher temperature = higher vapor pressure = greater cavitation risk

Always calculate Cv at actual operating temperatures, not ambient conditions.

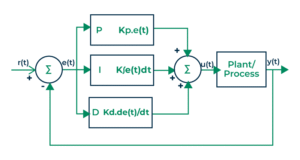

How to Calculate Cv for Control Valves

Control valves require additional considerations beyond the basic flow coefficient formula:

Sizing for Rangeability

A control valve should operate in its effective control range (typically 20-80% open):

Step 1 – Calculate Cv at maximum flow:

Cv_max = Q_max × √(SG / ΔP_max)

Step 2 – Calculate Cv at minimum controllable flow:

Cv_min = Q_min × √(SG / ΔP_min)

Step 3 – Check rangeability:

Rangeability = Cv_max / Cv_min

Select a valve where both Cv values fall within the valve’s characteristic curve.

Installed Flow Characteristic

The valve flow coefficient varies with valve opening. Common characteristics:

- Linear: Cv increases proportionally with opening

- Equal percentage: Cv increases exponentially with opening

- Quick opening: Cv increases rapidly at low openings

Choose the characteristic based on your control requirements.

Common Mistakes When Calculating Valve Cv

Mistake 1: Using Wrong Pressure Units

Wrong: Mixing gauge and absolute pressure

- Gauge pressure: psig (pressure above atmospheric)

- Absolute pressure: psia (pressure above absolute zero)

Correct: For most liquid calculations, use psig for ΔP. For gas calculations, always use psia for inlet pressure P₁.

Mistake 2: Ignoring System Effects

The valve flow coefficient formula gives the Cv for the valve only. Real systems have additional losses:

- Pipe friction losses

- Fitting losses (elbows, tees, reducers)

- Inlet and outlet velocity effects

Solution: Add 15-25% safety margin to calculated Cv to account for piping effects.

Mistake 3: Oversizing Valves

Problem: “Bigger is safer” thinking leads to selecting Cv values 2-3 times larger than needed.

Consequences:

- Control valves operate near closed position (poor control)

- On-off valves experience cavitation and noise

- Higher cost

- Reduced valve life

Solution: Keep the valve Cv within 80-120% of calculated value.

Mistake 4: Neglecting Viscosity

Water-based calculations for viscous fluids lead to undersized valves.

Example error:

- Calculated Cv for oil using water formula: 25

- Actual required Cv with viscosity correction: 45

- Result: 80% undersized valve

Mistake 5: Wrong Flow Rate Units

The valve flow coefficient formula requires specific units:

- Liquids: Q must be in GPM (not m³/hr, L/min, etc.)

- Gases: Q must be in SCFH (not ACFM, Nm³/hr, etc.)

- Steam: W must be in lb/hr (not kg/hr, tons/hr, etc.)

Always convert to the correct units before calculating.

Cv vs Kv: Understanding Both Systems

North America uses Cv, while most other countries use Kv (metric flow coefficient).

Conversion Formulas

Cv to Kv: Kv = 0.865 × Cv

Kv to Cv: Cv = 1.156 × Kv

Definition Differences

- Cv: Flow in GPM of 60°F water with 1 psi drop

- Kv: Flow in m³/hr of 15°C water with 1 bar drop

Using Kv Formulas

For liquids with Kv:

Kv = Q × √(SG / ΔP)

Where:

- Q = Flow rate in m³/hr

- ΔP = Pressure drop in bar

Advanced Cv Calculation Considerations

Multi-Phase Flow

When handling mixed phases (liquid with gas bubbles, flashing liquids, condensing vapors), the standard valve flow coefficient formula doesn’t apply. These situations require:

- Specialized calculation methods

- Manufacturer technical support

- CFD analysis for critical applications

- Consideration of phase separation effects

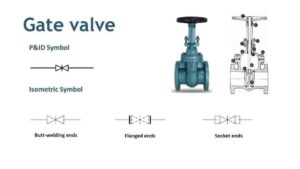

High-Recovery vs Low-Recovery Valves

Different valve designs have different pressure recovery characteristics:

Low-Recovery Valves (Globe, Angle):

- Less pressure recovery downstream

- Lower cavitation risk

- Use recovery factor FL = 0.85-0.95

High-Recovery Valves (Ball, Butterfly):

- More pressure recovery downstream

- Higher cavitation risk

- Use recovery factor FL = 0.55-0.75

For cavitating service, adjust the Cv calculation using the FL factor provided by the manufacturer.

Piping Geometry Effects

Valve installation configuration affects performance:

Reducer at inlet: Increases velocity → increases effective ΔP Expander at outlet: Decreases pressure recovery Short inlet piping: Creates turbulent flow distribution Elbows near valve: Cause asymmetric flow patterns

Use manufacturer piping factor (Fp) to correct Cv when installation isn’t ideal.

Practical Tips for Valve Cv Calculations

Quick Estimation Method

For water at typical pressure drops (5-15 psi), use this rule of thumb:

Cv ≈ Q / 3

Example: For 90 GPM water → Cv ≈ 30

This gives you a ballpark figure for initial sizing. Always perform the full calculation for final selection.

Verification Checklist

Before finalizing your Cv calculation, verify:

- ✓ Flow rate is at maximum expected condition

- ✓ Specific gravity is at operating temperature

- ✓ Pressure drop is allowable for system design

- ✓ Viscosity correction applied if needed

- ✓ Safety margin added (10-25%)

- ✓ Selected valve Cv is within available sizes

- ✓ Control valve will operate in 20-80% range

- ✓ Units are correct throughout calculation

Using Manufacturer Resources

Most valve manufacturers provide:

- Cv tables: Showing Cv at various valve positions

- Sizing software: Automated calculators with built-in corrections

- Technical support: Engineers to help with complex applications

- Cv curves: Graphical representation of Cv vs opening

Always verify your hand calculations against manufacturer data.

Documentation Best Practices

For every Cv calculation, document:

- All input parameters and their sources

- Assumptions made (temperature, viscosity, etc.)

- Formula used and calculation steps

- Safety factors applied

- Final valve selection with manufacturer and model

This documentation is invaluable for future troubleshooting or system modifications.

When to Use Different Calculation Methods

Simple Hand Calculation

Use when:

- Standard liquid at normal conditions

- Non-critical application

- Quick feasibility study

- Replacement of existing valve

Limitation: Doesn’t account for all system effects

Manufacturer Software

Use when:

- Complex fluid properties (high viscosity, two-phase)

- Critical application requiring accuracy

- Control valve with specific characteristic needed

- Multiple operating conditions to evaluate

Advantage: Includes proprietary correction factors

Professional Engineering Analysis

Use when:

- Severe service (cavitation, flashing, high velocity)

- Custom valve design needed

- System optimization required

- Regulatory compliance documentation needed

Benefit: Comprehensive analysis including CFD if necessary

Troubleshooting Cv Calculation Problems

Problem: Calculated Cv doesn’t match available valve sizes

Solution 1: Reconsider allowable pressure drop

- Increase ΔP to reduce required Cv

- Check if system can handle higher pressure drop

Solution 2: Consider different valve type

- Some designs offer wider Cv ranges

- May need larger line size with reducer

Problem: Cv seems unreasonably high or low

Check:

- Unit conversions (most common error)

- Specific gravity value (verify at operating temp)

- Pressure drop is differential, not absolute

- Flow rate represents maximum condition

Problem: Control valve operates outside desired range

Solution:

- Recalculate Cv for actual operating range

- Consider valve with different trim

- May need different control characteristic

- Check for system head curve changes

Conclusion: Mastering the Valve Flow Coefficient Formula

Calculating valve Cv accurately is fundamental to successful valve selection and system design. The valve flow coefficient formula provides the mathematical foundation, but proper application requires understanding of:

- Fluid properties and their variations with temperature

- System operating conditions and pressure drop allocation

- Valve characteristics and recovery factors

- Safety margins and installation effects

Start with the basic liquid formula, master the calculations through practice, and progressively handle more complex applications. Always verify your calculations, use appropriate safety margins, and don’t hesitate to consult with valve manufacturers for challenging applications.

With the formulas, examples, and practical guidance provided in this guide, you now have the tools to confidently calculate valve Cv for your applications and avoid the common pitfalls that lead to incorrect valve sizing.

Quick Reference: Essential Formulas

Liquids: Cv = Q × √(SG / ΔP)

Q in GPM, ΔP in psi

Gases: Cv = Q × √((SG × T) / (1360 × ΔP × P₁))

Q in SCFH, T in °R, P₁ in psia

Steam: Cv = W / (2.1 × P₁ × √(1 + ΔP/P₁))

W in lb/hr, P₁ in psia

Flow Rate: Q = Cv × √(ΔP / SG)

Pressure Drop: ΔP = (Q / Cv)² × SG

Cv to Kv: Kv = 0.865 × Cv

Safety Margin: Cv_final = Cv_calculated × 1.15

Quick Estimate (water): Cv ≈ Q / 3