Ball valve torque is the amount of rotational force needed to operate (open or close) a ball valve. Selecting the correct torque is critical for:

Choosing the right actuator

Ensuring smooth operation

Preventing stem failure

Avoiding under-powered or oversized actuators

This guide provides ball valve torque charts, explains factors that change operating torque, and gives simple rules of thumb for actuator sizing.

Table of Contents

ToggleWhat Is Ball Valve Torque?

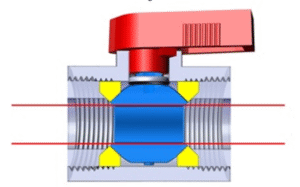

Ball valve torque = force required to rotate the ball from fully open to fully closed.

Units:

in-lb, ft-lb, or Nm

Two common torque values:

Breakaway torque (highest) – needed at initial movement

Running torque – lower, required during rotation

Seating torque – final torque to fully close and seal

Actuator sizing is always based on breakaway torque.

Ball Valve Torque Chart (General Reference)

⚠️ Actual torque varies by brand, seat material, pressure rating, and media. This chart shows typical ranges for standard industrial ball valves.

1. Quarter-Turn Ball Valve Torque Chart (Clean Water Service)

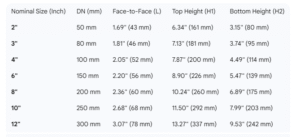

(Typical PTFE seats, stainless or brass, ≤ 150 psi)

| Valve Size | Typical Breakaway Torque (in-lb) | Typical Torque (Nm) |

|---|---|---|

| 1/4″ | 20–30 in-lb | 2–3 Nm |

| 3/8″ | 25–35 in-lb | 3–4 Nm |

| 1/2″ | 40–60 in-lb | 5–7 Nm |

| 3/4″ | 60–100 in-lb | 7–11 Nm |

| 1″ | 100–150 in-lb | 11–17 Nm |

| 1-1/4″ | 150–220 in-lb | 17–25 Nm |

| 1-1/2″ | 200–300 in-lb | 23–34 Nm |

| 2″ | 300–450 in-lb | 34–50 Nm |

| 2-1/2″ | 600–900 in-lb | 68–102 Nm |

| 3″ | 900–1500 in-lb | 102–170 Nm |

| 4″ | 1500–3000 in-lb | 170–340 Nm |

| 6″ | 4000–8000 in-lb | 450–900 Nm |

2. High-Pressure Ball Valve Torque Chart (1000–3000 psi)

(Metal seats, high-pressure service)

| Size | Breakaway Torque (in-lb) | Notes |

|---|---|---|

| 1/4″ | 70–120 | Much higher due to seat loading |

| 3/8″ | 80–130 | — |

| 1/2″ | 120–200 | — |

| 3/4″ | 200–350 | — |

| 1″ | 350–550 | — |

| 1-1/2″ | 700–1200 | — |

| 2″ | 1200–2000 | — |

High pressure + metal seats = much higher torque.

3. Pneumatic Actuator Sizing Rule of Thumb

📌 Actuator Torque ≥ 1.3 × Valve Breakaway Torque

(30% safety factor)

For sticky media (slurry, oil, chemicals):

Use 1.5–2.0× safety factor

What Increases Ball Valve Torque?

Torque increases when:

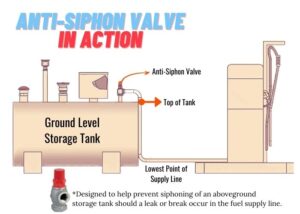

✔️ High differential pressure

✔️ Thick or viscous media (oil, glycol, slurry)

✔️ High seat load (metal or reinforced seats)

✔️ Long periods without operation

✔️ Scale, deposits, corrosion

✔️ High temperature service

✔️ Dry media (steam, gas)

If anything in your system matches these, apply a larger safety margin.

Ball Valve Torque Calculation Formula

For liquid service (simplified industry version):

T = T₀ + (ΔP × K × A)

Where:

T = operating torque

T₀ = base torque (seats + friction)

ΔP = differential pressure across valve

A = ball port area

K = seat friction coefficient (depends on material)

Manufacturers usually provide T₀ and K, so engineers plug in system pressure.

How to Select an Actuator Using the Torque Chart

Step 1: Find breakaway torque from chart

e.g., a 2″ ball valve at 150 psi → 400–450 in-lb

Step 2: Apply safety factor

400 in-lb × 1.3 = 520 in-lb required

Step 3: Choose actuator size

Pick the next highest actuator rating.

Ball Valve Torque Chart (Quick PDF-Style Summary)

| Size | Torque | Good for |

|---|---|---|

| 1/4″–1/2″ | 20–60 in-lb | Small automation, HVAC |

| 3/4″–1″ | 60–150 in-lb | Water service |

| 1-1/4″–2″ | 150–450 in-lb | Industrial service |

| 2-1/2″–4″ | 900–3000 in-lb | Processing industry |

| 6″+ | 4000–8000 in-lb | Heavy industrial |