The Multiport Valve MPV) is built for durability, but its internal gaskets and seals are subject to constant water flow, pressure, and chemical exposure. A malfunctioning valve can lead to poor filtration, wasted water, and even pump damage.

This article guides you through diagnosing common MPV failures and provides step-by-step instructions on how to perform simple repairs or a full pool multiport valve replacement.

Table of Contents

ToggleI. Common Multiport Valve Failures and Diagnosis

| Symptom | Location | Likely Cause | Solution |

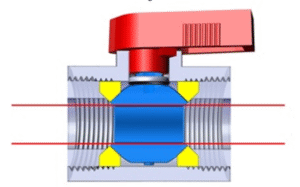

| 1. Continuous Leak from the Waste Port | Waste/Backwash Line | Worn/Damaged Spider Gasket (the internal seal). The gasket is failing to seal the Waste port when in the Filter position. | Replace the internal Spider Gasket (O-ring seal). |

| 2. Water Leaking from the Handle/Bonnet | Top of the valve/Stem | Worn Stem O-rings or loose assembly. | Replace the O-rings around the stem. |

| 3. Cloudy Water After Backwash | Pool Return Line | Spider Gasket Leak mixing dirty backwash water into the return line. | Replace the Spider Gasket and repeat the Rinse cycle. |

| 4. Difficulty Moving the Handle | Handle/Lever | Mineral/Chemical Build-up on the stem or internal seal, causing stiffness. | Use a non-petroleum based lubricant on the handle/stem. |

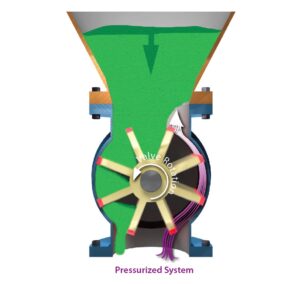

| 5. Low Flow/High Pressure | Filter/System | Internal Flow Restriction caused by a jammed or improperly seated diffuser. | Disassemble the top and check the internal piston/seal assembly. |

II. Step-by-Step DIY Multiport Valve Replacement

When the main valve body is cracked, severely corroded, or if gasket replacement fails to fix the leak, a full multiport valve replacement is necessary.

1. Preparation and Safety

Crucial Safety Step: Turn OFF all power to the pool pump at the breaker.

Drain Pressure: Relieve any pressure in the system by opening the air bleeder valve on the filter tank.

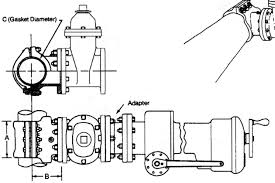

Required Parts: Ensure you have the correct new valve. Match the Make, Model, and Port Size (1.5” or 2.0”) of your existing filter.

Tools: PVC cutter or hacksaw, wrench, screwdriver, PVC primer, PVC cement (if using slip connections), and Teflon tape (if using threaded connections).

2. Disconnecting the Old Valve

Plumbing Disconnect: Depending on your setup:

Threaded Connections: Use a wrench to carefully unscrew the unions or threaded fittings on the return and waste lines.

Glued (PVC) Connections: Use the PVC cutter to cut the pipe sections connecting the valve, leaving enough pipe length on the existing runs for the new couplings.

Filter Disconnect:

Top-Mount Valve: Remove the flange clamp band connecting the valve to the filter tank.

Side-Mount Valve: Unscrew the threaded bulkhead fitting or union connecting the valve to the filter tank.

3. Installing the New Valve

Preparation: Clean the exposed pipe ends thoroughly. Apply PVC primer to both the pipe ends and the inside of the new couplings/valve ports.

Mounting: Seat the new MPV onto the filter tank. Ensure the main internal standpipe is aligned with the diffuser tube inside the tank. Secure the flange clamp band or threaded fitting.

Plumbing Connection: Apply PVC cement to the primed surfaces and quickly join the pipes to the new valve ports. Hold the pipes firmly for 30 seconds to set the cement.

Cure Time: Allow the PVC cement to cure according to the manufacturer’s instructions (usually 2 to 24 hours) before pressurizing the system.

4. Post-Replacement Startup

Set the new MPV handle to BACKWASH.

Turn the pump ON (briefly, for 30 seconds) to remove any debris or air. Turn the pump OFF.

Set the valve to RINSE and run the pump for 30 seconds. Turn the pump OFF.

Set the valve to FILTER and resume normal operation. Crucially, check all new connections for leaks.

By following these guidelines, you can ensure a reliable sand filter valve replacement and restore your pool system to optimal performance.