The choice between a Basket Strainer and a Y-Strainer is critical for protecting downstream equipment (pumps, meters, valves) from solid contaminants in a pipeline. While both perform the essential function of filtration, their design, capacity, and suitability for different applications vary significantly.

This article compares the fundamental differences between these two common industrial filter types, helping you decide which is best for your specific needs.

Table of Contents

Toggle1. Y-Strainer (Wye Strainer)

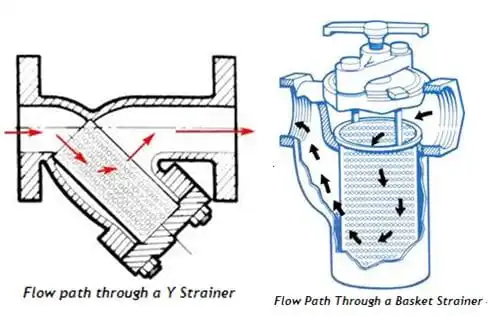

The Y-Strainer gets its name from its characteristic “Y” shape, with the filtration element (screen or mesh) angled off the main flow path.

Design and Flow

Structure: Compact, with the filter element housed in a leg angled typically 45° to 60° from the main pipeline.

Filtration: The flow must change direction to pass through the screen.

Installation: Can be installed horizontally or vertically (with the leg pointing downward). The downward angle allows solids to collect at the bottom away from the main flow.

Suitability and Maintenance

Capacity: Designed for low debris loading and continuous service. The screen volume is relatively small.

Cleaning: Requires system shutdown to access the screen (by removing the blow-off plug or cover), making cleaning less convenient.

Pressure Drop: Offers a slightly higher pressure drop compared to a clean basket strainer due to the flow change.

Cost: Generally less expensive due to its simpler design.

Best For: Steam, gases, and clean liquid lines where solid debris is minimal and infrequent.

2. Basket Strainer

The Basket Strainer is named for its vertical, bucket-shaped screen, which is easily accessible from the top.

Design and Flow

Structure: Features a larger body where the flow passes down through the basket.

Filtration: Offers a straight-line flow path, minimizing the change in direction and reducing pressure loss.

Installation: Must be installed horizontally to ensure the debris collects uniformly in the basket and to allow access for removal.

Suitability and Maintenance

Capacity: Designed for high debris loading or services where solids are expected to accumulate quickly. The large screen volume allows for longer intervals between cleaning.

Cleaning: Extremely convenient. The cover is removed, and the basket is lifted out quickly for cleaning without disconnecting the main plumbing. This is often achievable with no system shutdown (in duplex basket strainers, see below).

Pressure Drop: Offers a very low pressure drop when clean due to the large filtration area and straight flow path.

Cost: Generally more expensive than Y-strainers due to the more complex body casting and larger volume.

Best For: Water, cooling towers, industrial liquids, and applications requiring easy maintenance, especially systems with medium to high levels of suspended solids.

3. Direct Comparison

| Feature | Y-Strainer | Basket Strainer |

| Maintenance | Inconvenient (requires tools and shutdown) | Very convenient (basket lifts out) |

| Debris Capacity | Low (small screen volume) | High (large screen volume) |

| Pressure Drop | Moderate (flow path changes) | Low (straight-line flow) |

| Installation | Horizontal or Vertical (leg down) | Must be Horizontal |

| Cost | Lower | Higher |

| Best Application | Steam, Gases, Low Solid Content Liquids | Water, High Solid Content Liquids, Continuous Operation |

4. Special Application: Duplex Basket Strainers

A significant advantage of the basket strainer design is the feasibility of the Duplex (or double) arrangement.

A Duplex Basket Strainer consists of two parallel basket strainer bodies with valves (typically butterfly or ball valves) located between them. This setup allows the operator to:

Switch the flow from the fouled basket to the clean basket without shutting down the system.

Clean the fouled basket while the system remains operational.

Duplex Basket Strainers are the ideal choice for critical, continuous-operation processes (e.g., cooling lines, main water supply to a plant) where downtime for cleaning is unacceptable.