Safety valves—also known as pressure relief valves (PRVs)—are the most critical protection devices in any pressurized process system. When system pressure rises beyond equipment limits due to fire, process upsets, control failure, or thermal expansion, a properly sized safety valve prevents catastrophic failure.

This comprehensive guide explains everything engineers must know about safety valve selection, sizing, installation, and overpressure analysis. It is optimized for search engines and written to help process, mechanical, and piping engineers make correct design decisions in accordance with API 520, API 521, GB150, and HG/T 20570.

Table of Contents

Toggle1. What Is a Safety Valve?

A safety valve is an automatic pressure-relief device designed to open rapidly when system pressure reaches its set point, release enough fluid to keep pressure within safe limits, and then close automatically when pressure returns to normal.

Safety valves are used in:

chemical plants

refineries

boilers and pressure vessels

piping systems

storage tanks

heat exchangers

A safety valve must be correctly selected, installed, and sized to ensure the equipment is protected under all credible overpressure scenarios.

2. Key Safety Valve Terminology

| Term | Meaning |

|---|---|

| Set Pressure | Pressure at which the valve begins to open. |

| Overpressure | Pressure increase above set pressure during relief (%). |

| Relieving Pressure | Set pressure + overpressure. |

| Blowdown | Pressure at which the valve reseats. |

| Actual Orifice Area | The smallest internal flow area of the valve. |

| Effective Discharge Area | The minimum calculated flow area needed for relief. |

| Built-Up Backpressure | Backpressure from fluid flow in the discharge pipe. |

| Maximum Allowable Working Pressure (MAWP) | Maximum vessel pressure allowed by code. |

These terms are essential for calculations under API 520 and GB150.

3.Safety Valve Pressure Requirements

Reference Basis: Design Pressure

| Pressure Percentage | Safety Valve Condition / Meaning |

|---|---|

| 121% of Design Pressure | Maximum relieving pressure for fire-case safety valves |

| 116% of Design Pressure | Maximum relieving pressure for non-fire auxiliary safety valves |

| 110% of Design Pressure | – Maximum relieving pressure for non-fire primary (main) safety valves – Maximum set pressure for fire-case auxiliary safety valves |

| 105% of Design Pressure | Maximum set pressure for non-fire auxiliary safety valves |

| 100% of Design Pressure | Maximum set pressure for the primary (main) safety valve |

| 93% – 97% of Design Pressure | Reseating pressure (blowdown range) of safety valves |

4. Types of Safety Valves

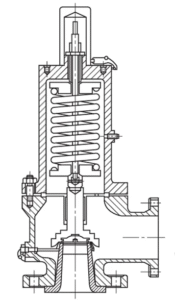

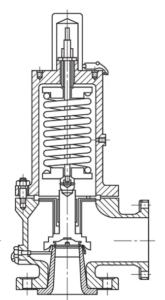

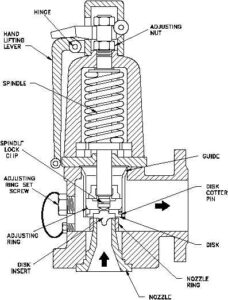

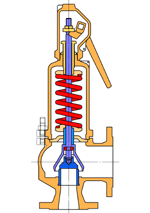

4.1 Conventional Spring-Loaded Safety Valve

Uses spring force to hold the disc closed

Sensitive to backpressure

Widely used for air, steam, and process gases

4.2 Balanced Bellows Safety Valve

Bellows isolates the spring from backpressure

Suitable for systems with variable backpressure

Recommended for toxic or corrosive fluids

4.3 Pilot-Operated Safety Valve (POSV)

Uses pilot valve for precise control

Suitable for high set pressure, tight blowdown, and high backpressure

Ideal for gas-heavy systems

4.4 Modulating (Proportional) Safety Valve

Opens proportionally to overpressure

Best for liquid relief applications

4.5 Full-Lift (Pop-Action) Safety Valve

Opens fully and instantly at set pressure

Optimal for compressible fluids (steam/gas)

5. Safety Valve Selection Guide

| Application Scenario | Recommended Valve Type |

|---|---|

| Gas / steam relief | Full-lift / spring-loaded |

| Liquid relief | Modulating or full-lift |

| Toxic / corrosive media | Balanced bellows |

| High backpressure | Balanced bellows or pilot-operated |

| High temperature (>235°C) | Finned safety valve |

| Critical equipment | Dual safety valves with interlock |

| Dirty or polymerizing fluids | Use rupture disc, not safety valve |

6. Installation Requirements (API + GB150)

Safety valves must be installed where:

Pressure energy sources exist (compressors, pumps, heaters)

Upstream pressure can exceed downstream design limits

Thermal expansion can trap liquid

Positive displacement pumps cannot be dead-headed

Fire exposure is possible

Heat exchanger tube rupture is a credible scenario

If fluid can solidify, polymerize, or crystallize, a rupture disc is mandatory.

7. Causes of Overpressure & Relief Load Calculation

7.1 Common Overpressure Scenarios

| Scenario | Relief Load Basis |

|---|---|

| Outlet valve closed | Maximum normal flow |

| Pump dead-headed | Pump curve shutoff pressure |

| Cooling water failure | Max vapor load to condenser |

| Heater control valve failed open | Total heat input |

| Control valve failure | Depends on fail-open or fail-close position |

| Tube rupture in heat exchanger | Flow from high-pressure side |

| Fire exposure | API 521 fire case formula |

8. Safety Valve Sizing Formulas (API 520 / GB150)

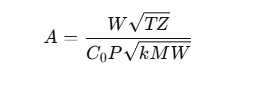

8.1 Gas and Vapor Sizing Formula

Where:

WWW = mass flowrate

ZZZ = compressibility

kkk = heat capacity ratio

MWMWMW = molecular weight

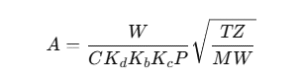

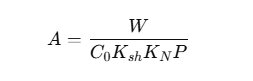

8.2 API 520 Gas Sizing (with correction factors)

| Factor | Meaning |

|---|---|

| Kd | discharge coefficient |

| Kb | backpressure factor |

| Kc | combination factor (with rupture disc) |

8.3 Steam (Napier Formula)

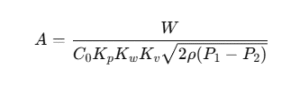

8.4 Liquid Sizing

Factors included:

liquid viscosity factor Kv

backpressure factor Kw

8.5 Two-Phase Flow Sizing

Procedure:

Determine flash fraction

Calculate vapor-phase area

Calculate liquid-phase area

Total area = A_v + A_l

This is heavily used for LPG, refrigerants, and hydrocarbon mixtures.

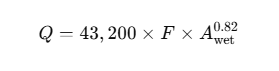

9. Fire Case Sizing (API 521)

9.1 Heat Input Formula

Where:

Awet = wetted surface area

F = fire exposure factor

9.2 Fire Factor Table

| Condition | F |

|---|---|

| Bare vessel | 1.0 |

| Water deluge | 0.6 |

| Sand-covered | 0.3 |

| Insulated | Refer to API formula |

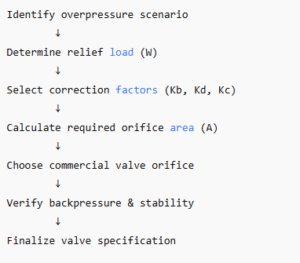

10. Engineering Infographic Blocks

10.1 Safety Valve Sizing Workflow

10.2 Safety Valve Selection Checklist

Fluid: gas / liquid / steam / two-phase

Set pressure = MAWP

Overpressure limit: 10%, 16%, or 21%

Built-up backpressure

Toxic/corrosive? Use bellows

Clean or dirty service?

Required capacity under fire case

11. Frequently Asked Questions

Q1: How do I choose between a safety valve and a rupture disc?

Use rupture discs when the fluid can polymerize, crystallize, or foul the valve.

Q2: How many safety valves are required?

At least one; critical equipment often uses two with isolation interlocks.

Q3: Can backpressure affect valve operation?

Yes. Balanced bellows or pilot-operated designs may be required.