In critical industrial environments—particularly oil and gas, petrochemicals, and power generation—safety and zero-leakage isolation are paramount. The answer to “What is a Block and Bleed (B&B) Valve?” defines a vital safety protocol, not just a single component. A B&B system is an arrangement of valves that provides a guaranteed method of isolating pressure from a system or piece of equipment, allowing for safe access, repair, or monitoring.

A block and bleed valve is a safety device in fluid systems that combines isolation (block) and pressure relief (bleed) functions, allowing you to safely shut off fluid flow and vent trapped pressure for maintenance, calibration, or equipment isolation. It typically features one or more main “block” valves to stop flow and a smaller “bleed” valve between them to release residual fluid or gas, preventing hazards during servicing.

The core principle involves creating a verifiable double barrier against fluid flow, making B&B technology an essential best practice for hazardous and high-pressure service.

Table of Contents

Toggle🛡️ The Mechanism: How Block and Bleed Works

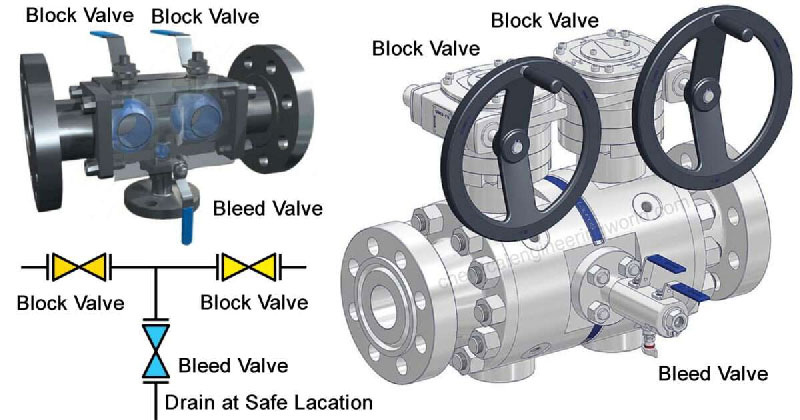

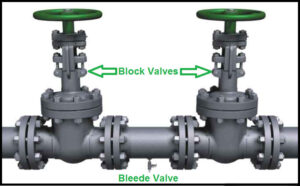

A Block and Bleed system uses three valves arranged in sequence:

Block Valve (Upstream): The first valve in the system, installed closest to the fluid source. Its job is to block the flow.

Bleed Valve (Center): A smaller valve located in the space between the two block valves. Its purpose is to drain or vent any trapped fluid.

Block Valve (Downstream): The second valve, providing a redundant barrier to ensure zero leakage downstream.

The Isolation Procedure:

Step 1: Block: The upstream and downstream block valves are closed. This traps any residual fluid or pressure in the short section of pipe between them.

Step 2: Bleed: The central bleed valve is opened. This vents the trapped pressure or drains the fluid from the cavity to a safe location (e.g., a flare, a drain, or the atmosphere).

Step 3: Verification: By successfully venting the pressure to zero, the operator receives verifiable assurance that the isolation is absolute—there is no pressure reaching the downstream side of the equipment.

🔑 Why B&B is Essential: The Principle of Double Isolation

The primary reason to use a Block and Bleed Valve configuration is to achieve Double Isolation, which is mandatory under many safety regulations.

Redundancy and Safety

If a single valve is used for isolation, and its seal fails (due to seat wear, dirt, or thermal changes), the high-pressure fluid can leak through the barrier. This leakage poses a severe safety hazard to technicians working downstream.

By contrast, with two block valves, the failure of the first seal is safely contained by the second seal. The central bleed valve then confirms that the entire system is depressurized, making the area downstream safe to open for maintenance (known as achieving a “zero-energy state”).

Monitoring and Calibration

The B&B system is also critical for accurately isolating instruments like pressure gauges or transmitters. The bleed valve allows operators to vent the pressure to atmospheric conditions, which is essential for calibration checks and ensuring the instrument is reading correctly.

🚨 When is Double Block and Bleed Required? (DBB Requirements)

Understanding when is Double Block and Bleed required is a core aspect of process safety engineering. The requirement is not arbitrary; it is driven by regulatory mandates and strict risk assessment criteria.

1. Handling Hazardous and Flammable Media

Any line containing fluids that are toxic, flammable, or explosive demands DBB. If a leak occurs, the consequences are severe (fire, explosion, or environmental damage). The double seal is required to protect personnel and the facility from these catastrophic failures during line breaking or maintenance.

2. High-Pressure or High-Temperature Service

Systems operating at extreme pressures or temperatures are inherently higher risk. The stress on valve seals is greater, and the energy released from a leak is more damaging. DBB provides the necessary redundancy to manage this heightened risk profile.

3. Isolation Before “Breaking Containment”

DBB is typically required before any procedure that involves breaking containment—that is, opening a pipe or vessel to the atmosphere (e.g., replacing a flange gasket, removing a pump, or entering a vessel). This guarantees the section of the pipeline being opened is fully depressurized and isolated.

4. Code and Standard Compliance

Major industrial codes and standards, such as those published by API (American Petroleum Institute) and ASME (American Society of Mechanical Engineers), specifically mandate DBB for certain services, including:

Isolation of transfer pumps and compressors handling hydrocarbons.

Isolation of safety relief valves (PSVs) that must be removed for testing.

Isolation points where one process unit interfaces with another (battery limit isolation).

In essence, if the fluid or the operating conditions present a significant danger to human life or the environment upon leakage, the DBB configuration is the mandated standard for isolation.

🎯 Valve Configurations: Integral vs. Traditional

The concept of a B&B system can be implemented using two main physical configurations:

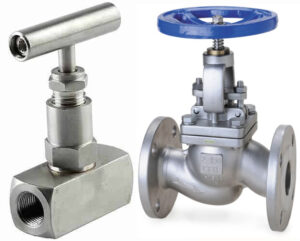

1. Traditional B&B (Three Separate Valves)

This involves installing three separate valves (two larger block valves, one smaller needle or ball bleed valve) and connecting them with pipe spools and fittings.

Pros: Highly flexible, allows selection of different valve types for different duties.

Cons: Higher number of flange connections and threaded joints, which increases potential leak points, requires a larger installation footprint, and is time-consuming to install.

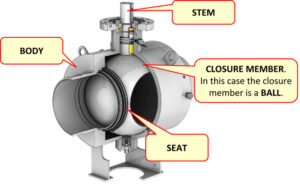

2. Integral B&B Valve (Single Unit)

This is a more modern, compact solution. A single valve body (like the Double Block and Bleed Ball Valve discussed previously) houses all three valves (two block elements and the central bleed port) within one piece of metal.

Pros: Dramatically reduces the number of leak paths, is easier and faster to install, and minimizes the physical footprint. This is the preferred solution for modern high-pressure isolation and instrument hook-ups.

Cons: Higher initial unit cost compared to buying three separate commodity valves.

🏭 Expert Summary: Where B&B Makes a Difference

Any application handling toxic, flammable, high-pressure, or high-temperature media should mandate a Block and Bleed valve arrangement. It transforms a simple shut-off operation into a guaranteed, verifiable safety protocol.

Whether utilizing the traditional three-valve manifold or the modern, compact integral valve, the Block and Bleed philosophy is the gold standard for achieving positive, safe, and absolute isolation in critical industrial pipelines.