When examining fluid systems, both the control valve and the check valve are fundamental components, yet they serve entirely distinct and non-interchangeable functions. The difference lies in their purpose: one actively manages fluid conditions, while the other passively prevents reverse flow. Understanding the core contrast between a control valve vs. check valve is essential for proper system design, ensuring both efficiency and safety.

Table of Contents

Toggle🎯 Control Valve: The Active Manager of Flow

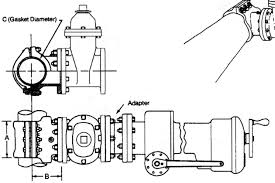

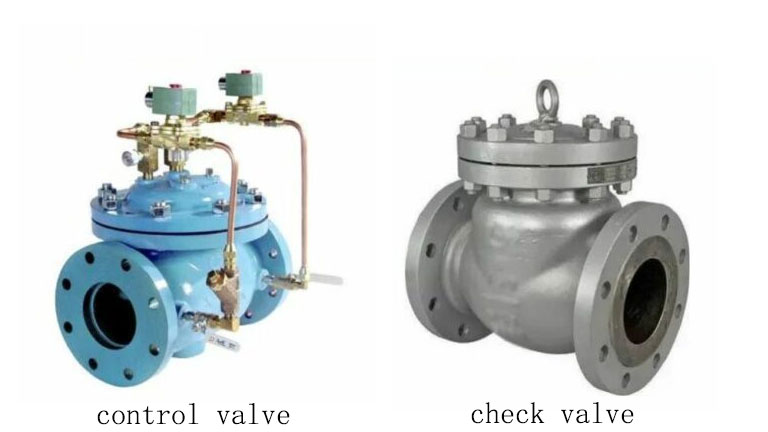

A control valve is a sophisticated device designed to actively regulate a fluid’s condition—most often flow rate, but also pressure, temperature, or liquid level. It works in conjunction with a control loop: a sensor measures the process variable (e.g., pressure), a controller calculates the required adjustment, and the control valve acts as the “final control element” to execute that change.

Key Characteristics of a Control Valve:

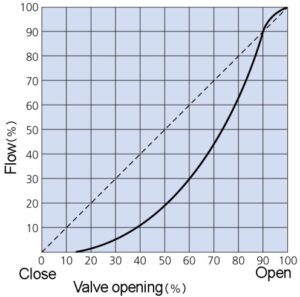

Primary Function: Modulation and Regulation. It is designed to operate in a partially open position (throttling) to manage the amount of fluid passing through.

Operation: Active. Requires an external power source (pneumatic air, electric actuator, or hydraulic fluid) and a sophisticated control signal (often 4-20 mA or digital).

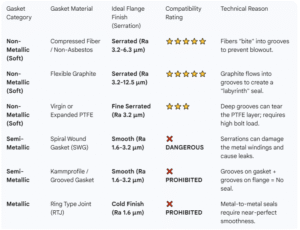

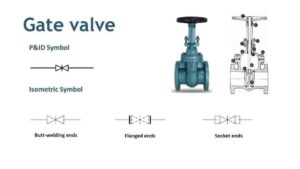

Structure: Typically a globe or specialized angle pattern valve, designed with specific trim shapes to provide a predictable and repeatable flow characteristic.

Application: Essential for process stability and quality. Examples include maintaining the level in a tank, controlling the temperature of steam, or regulating pressure reduction across a line.

Expert Note: Control valves must handle repeated movement and precise positioning. Their internal components (trim and seats) are engineered to withstand the erosive forces of continuous throttling.

↩️ Check Valve: The Passive Protector Against Backflow

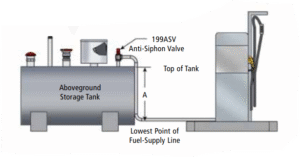

A check valve (also known as a non-return valve, foot valve, or one-way valve) is a simple, mechanical device whose purpose is to passively prevent fluid from reversing its direction of flow. It operates entirely on the differential pressure of the fluid system itself and requires no external power or control.

Key Characteristics of a Check Valve:

Primary Function: Prevention of Backflow (Anti-Siphon). It ensures flow moves only in the desired direction.

Operation: Passive. It opens when the upstream pressure is greater than the downstream pressure (plus the force needed to open the internal mechanism), and it automatically closes when the upstream pressure drops below the downstream pressure.

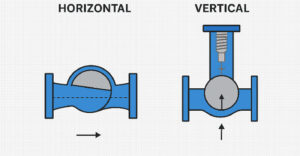

Structure: Common types include swing checks (a hinged disc), lift checks (a guided piston), and ball checks.

Application: Critical for protecting equipment. Used on the discharge side of pumps to prevent water hammer and reverse rotation, and in multi-process lines to prevent contamination or mixing.

📊 Control Valve vs. Check Valve: The Core Differences

The fundamental difference lies in their interaction with the process: the control valve imposes change, while the check valve reacts to change.

| Feature | Control Valve | Check Valve |

| Principle | Active Regulation | Passive Backflow Prevention |

| Power Required | Yes (Actuator & Control Signal) | No (Operates via Differential Pressure) |

| Flow Direction | Bi-directional (Doesn’t inherently prevent reverse flow) | Uni-directional (Only permits flow in one direction) |

| Position | Modulating (Partial Open) | Fully Open or Fully Closed (On/Off) |

| Control | External (Control System dictates position) | Internal (Fluid dynamics dictate position) |

| Cost & Complexity | High (Requires actuator, positioner, and controller) | Low (Simple mechanical component) |

🏭 Applications Where the Distinction is Vital

In Pump Systems

A Check Valve is always installed immediately downstream of a centrifugal pump to prevent the high-pressure fluid from flowing back when the pump shuts down, protecting the pump impeller and preventing water hammer.

A Control Valve might be installed further downstream in the pipeline to regulate the flow rate coming from that pump station, ensuring the destination vessel receives the exact amount of fluid required.

In Pressure Systems

A Control Valve actively reduces or holds a specific pressure level by adjusting its opening.

A Check Valve does nothing to regulate pressure; it simply prevents pressure from an area of higher pressure (downstream) from moving into an area of lower pressure (upstream).

The control valve is the ‘brain’ that manages the process variables, offering adaptability and precision. The check valve is the ‘guard’ that provides reliable, automatic, mechanical safety against catastrophic reverse flow events. Both are indispensable, but their distinct roles must be respected in any successful fluid handling system.