If you’re facing a sprinkler zone that won’t shut off or a valve that constantly leaks from the top, you likely need a full valve replacement. Searching for “How do I replace a sprinkler valve?” means you’re ready to tackle this essential irrigation repair yourself. Replacing a faulty valve is a critical maintenance task that restores water efficiency and prevents landscaping damage.

This comprehensive, step-by-step guide will walk you through the process, focusing on the techniques needed to successfully remove the old unit and install the new one, ensuring a professional, leak-free repair.

Table of Contents

Toggle🛠️ Step 1: Preparation, Safety, and Diagnosis

Before starting any cutting or wiring, proper preparation is non-negotiable.

A. Gather Your Materials

Ensure you have the correct new sprinkler valve (matching the pipe size, typically $3/4$ inch or 1 inch, and connection type—threaded or PVC glue). You will also need:

Shovel/Trowel, towels, wire cutters/strippers.

Pipe cutter or hacksaw.

For Threaded Valves: Teflon Tape (PTFE Tape).

For Glued PVC Valves: PVC Primer and Cement (ensure they match your pipe type).

Waterproof wire connectors (e.g., grease-filled wire nuts).

B. Shut Down the System

Safety First: Locate the main water source isolation point for your irrigation system and turn the water OFF completely.

Depressurize: Briefly run a zone on your controller or use the manual bleed screw on the faulty valve to release residual pressure.

Excavate: Remove the valve box lid and carefully dig away the soil around the faulty valve, exposing all pipe connections and wires.

⚡ Step 2: Electrical Disconnection

You must safely detach the valve’s power source before removal.

Identify Wires: Note the two wires coming from the solenoid (the small cylinder): the shared Common Wire (usually white) and the specific Hot/Zone Wire (usually a different color).

Cut the Connections: Use wire cutters to sever the connection to the faulty valve, leaving sufficient slack on the main wiring bundle for reconnection later.

Insulate and Secure: Ensure the main wires are safely separated and tucked away from the damp work area.

🔪 Step 3: Removing the Old Sprinkler Valve

The removal method hinges entirely on the connection type.

A. For Threaded Valves (Easier to Replace)

Unscrew: Hold the pipe connections firmly and carefully unscrew the couplings or fittings attached to the old valve body.

Expert Tip: Use a pipe wrench gently. If the valve is old and brittle, excessive force can break the adjacent pipework.

B. For Glued PVC Valves (Requires Cutting)

Measure Twice, Cut Once: This is critical. Use a tape measure to determine the length of the new valve body.

Cut Cleanly: Use a hacksaw or pipe cutter to make straight, perpendicular cuts on the PVC pipes on both the inlet and outlet sides of the old valve. Ensure you leave enough clean, undamaged pipe stub for the new valve or repair couplings to slide onto.

Remove Debris: Clean up any plastic shavings from the cut ends.

🔩 Step 4: Installing the New Sprinkler Valve

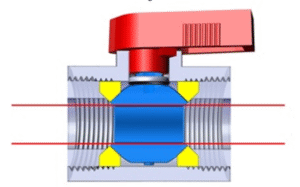

Proper installation ensures a reliable, leak-free connection. Always check the flow arrow on the new valve body and ensure it points in the direction of the water flow (away from the main line).

A. Installing Threaded Valves

Apply Sealing Agent: Wrap the male threads of the pipe fittings with Teflon Tape (PTFE Tape), wrapping clockwise (in the direction you will tighten). This creates a watertight seal.

Connect: Screw the new valve securely onto the pipe connections.

B. Installing Glued PVC Valves

Dry Fit: Assemble the new valve and any necessary couplings to confirm the overall length matches the removed section.

Prime: Apply PVC primer generously to the outside of the pipe ends and the inside of the new valve’s sockets.

Cement: Apply PVC cement to the primed areas, quickly push the pipe and valve firmly together, ensuring the valve is oriented correctly. Hold the connection for about 30 seconds to allow the cement to bond. Allow the cement to cure before proceeding to the next step.

🔌 Step 5: Electrical Reconnection and Testing

This step revitalizes your zone.

Strip and Twist: Strip a small section of insulation from the new solenoid wires and the matching common and zone wires. Twist the corresponding pairs together firmly.

Waterproof Connection: Screw on new, grease-filled, waterproof wire nuts. Twist the nut until you see the wires begin to twist inside the plastic; this confirms a solid electrical connection.

Initial Leak Check: Slowly turn the main water supply back ON. Check the new connections for any leaks. Tighten threaded connections slightly if necessary.

Functional Test: Use your sprinkler controller to run a manual cycle for the newly repaired zone. Verify that the sprinklers operate correctly and, most importantly, that the valve shuts OFF completely when the cycle ends.

Once the operation is confirmed leak-free and functional, gently backfill the area with soil and replace the valve box lid. By following these steps, you have successfully mastered how to replace a sprinkler valve, restoring reliability to your system.