A control valve leak is more than just a nuisance; it’s a direct indicator of system inefficiency, product loss, and potential safety hazard. Whether the leak is escaping the valve body externally or bypassing the seat internally, it signifies a failure in containment that demands immediate valve maintenance. Ignoring a leak compromises the valve’s ability to accurately control the process, leading to instability and increased operational costs.

This guide details all common types of control valve leaks, provides quick diagnostic tests, and outlines professional steps for effective control valve repair service.

Table of Contents

Toggle1. All Types of Control Valve Leaks (Internal vs. External)

Control valve leaks fall into two main categories, each requiring a distinct repair approach:

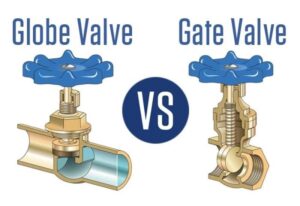

A. Internal Leak (Seat Leakage / Through Leakage)

What It Is: Process fluid bypasses the closed plug and seat assembly and continues to flow downstream.

Consequence: The valve fails to achieve positive isolation, leading to product waste, overheating in heat exchangers, and inability to safely maintain equipment downstream. Internal leakage necessitates valve refurbishment of the trim.

Diagnosis: Monitoring downstream pressure or temperature when the valve is commanded fully closed. A rise in these variables confirms internal leakage.

B. External Leak (Containment Leakage)

What It Is: Process fluid escapes the valve body and enters the surrounding environment.

Consequence: Safety hazards (if the fluid is flammable or toxic), environmental non-compliance, and degradation of equipment components surrounding the valve.

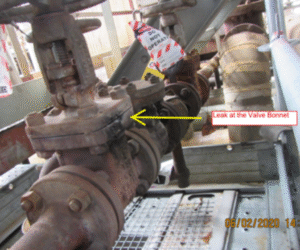

Diagnosis: Visible moisture, staining, or crystallization around the bonnet, packing, or body flange.

2. Quick Tests to Identify the Leak Source

Before disassembling the valve, use non-invasive tests to pinpoint the failure area.

| Leak Location | Quick Test / Symptom | Likely Cause |

| Internal (Seat) | Check downstream pressure/flow with the valve commanded to 0%. | Worn trim components (plug/seat), debris stuck on the seat, or incorrect actuator seating force. |

| Stem/Packing | Visible drip or seepage along the valve stem while the valve is cycling. | Degraded stem packing (hardened, cracked), loose packing flange bolts, or damaged stem surface. |

| Bonnet Gasket | Leakage visible between the bonnet (top housing) and the main body of the valve. | Failed bonnet gasket, or bonnet bolts incorrectly torqued (unevenly or loosely). |

| Body/Flange | Leakage at the pipeline connection (flanges). | Failed flange gasket, corrosion on the flange face, or improper bolt torque. |

3. How to Stop the Leak: Fixes for Common Locations

Safety Protocol: Always isolate, depressurize, and drain the line before performing any control valve repair service.

A. Fixes for Stem/Packing Leaks (Most Common External Leak)

Tighten Packing: If the leak is minor, try slightly increasing the torque on the packing flange nuts. Caution: Overtightening increases stem friction, causing stickiness and poor control.

Replace Packing Set: If tightening fails, the packing material is usually worn or hardened. The valve must be isolated, and the old packing set must be fully replaced using the correct valve maintenance kit. Ensure new packing is installed according to the manufacturer’s specified procedure and torque.

B. Fixes for Bonnet and Gasket Leaks

Tighten Bolts: Check and ensure the bonnet bolts are torqued evenly across the bonnet flange to the manufacturer’s specification.

Replace Gasket: If the leak persists, the gasket is cracked or deformed. The valve must be isolated, the bonnet removed, and the bonnet gasket replaced. Always use new, manufacturer-specified gaskets.

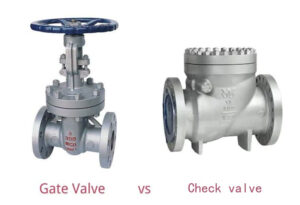

C. Fixes for Internal (Seat) Leaks

Flush Debris: Briefly cycle the valve fully open and closed several times (if process conditions allow) to attempt to dislodge any debris stuck between the plug and seat.

Full Trim Replacement: If cycling fails, the plug and/or seat is damaged by erosion, cavitation, or wear. This requires full isolation and disassembly of the valve body to install a new, matched trim set (seat ring, plug, and possibly the cage). This often falls under extensive valve refurbishment.

4. When Leaks Require Full Refurbishment

A simple seal replacement is minor valve maintenance, but structural issues and severe trim damage necessitate professional refurbishment.

Deep Corrosion: If the leak is caused by corrosion or wall thinning on the main valve body casting itself, the structural integrity is compromised. This requires sending the valve to a certified valve repair service for welding repair and hydrostatic testing.

Trim Erosion: Severe internal leaks often mean the fluid has deeply eroded the seat and plug material. A professional shop can accurately machine or lap the seating surfaces to restore Class IV or better shutoff, or install a complete new trim kit.

Safety Criticality: For valves in hazardous service (high pressure, toxic, or flammable media), any internal or external leak mandates immediate removal and professional overhaul, including certified seat leak testing to verify Class VI or V shutoff before returning to service.

Regular valve maintenance and prompt action on the first sign of a control valve leak are the most effective ways to prevent minor issues from escalating into expensive, safety-critical failures.