Table of Contents

ToggleAbstract: The Distinct Roles of Two Essential Valves

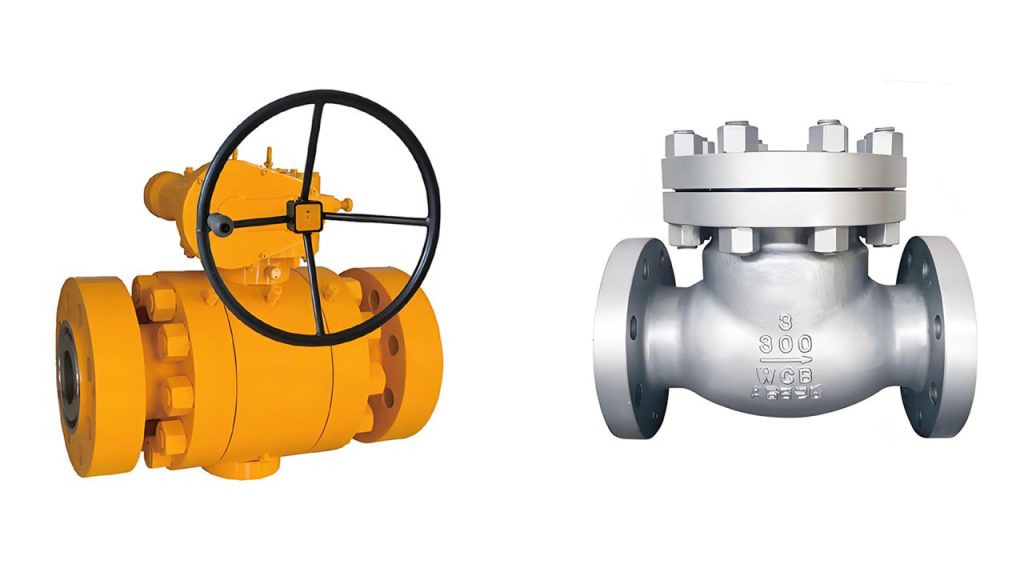

In any fluid control system, the Ball Valve and the Check Valve are among the most common and indispensable components. While the search volume for their combined terms is high, their functional roles are strictly different:

Ball Valve: Responsible for active isolation and shut-off of fluid flow (On/Off function).

Check Valve: Responsible for passive protection and unidirectional control (preventing backflow).

Understanding their individual principles and complementary relationship is key to ensuring a safe and efficient piping system.

Part I: The Ball Valve – The Powerhouse of Isolation and Shut-off

A Ball Valve utilizes a ball with a bore (port) as the closing element, which is rotated 90° by a stem within the valve seats to either open or close the flow path.

1. Structure and Working Principle

Core Component: A sphere with a hole through the center.

Operation: A quarter turn (90°) aligns the hole with the pipeline (fully open) or is perpendicular to the pipeline (fully closed).

Characteristics: Quick actuation, excellent sealing capability.

Types: Floating Ball, Trunnion, Full Port, Reduced Port, Segmented V-Notch (for limited control).

2. Advantages and Limitations

| Advantages (Pros) | Limitations (Cons) |

| Quick Operation: Fast opening and closing, suitable for emergency shut-off. | Poor Throttling Control: High wear on seats in partially open positions, risking seat damage. |

| Low Flow Resistance: Minimal pressure drop when fully open (straight-through flow path). | Fluid Retention: The ball cavity can trap media, making it unsuitable for certain high-purity or crystallizing fluids. |

| Compact Design: Relatively small size, easy to install and maintain. | Actuation Required: Cannot operate automatically without an actuator. |

3. Typical Application Positioning

Ball valves are primarily used as Isolation Valves, On/Off Valves, and emergency shut-off valves. They are utilized in scenarios requiring a fast and reliable cut-off of fluid supply.

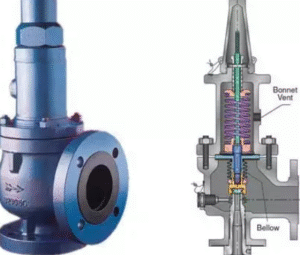

Part II: The Check Valve – The Sentinel of Passive Protection

A Check Valve, also known as a non-return valve or reflux valve, is designed to prevent backflow of medium in a pipeline. It operates without external assistance (manual or actuated), relying entirely on the fluid’s own flow dynamics.

1. Structure and Working Principle

Core Components: Disc, body, and seat.

Operation: Driven by the pressure differential of the medium:

Forward Flow: Medium pressure pushes the disc open, allowing flow.

Reverse Flow: Backflow pressure automatically forces the disc against the seat, closing the valve.

Characteristics: Passive operation, crucial for equipment safety.

Types: Swing Check, Lift Check, Ball Check, Wafer Check, Tilting Disc.

2. Typical Application Positioning

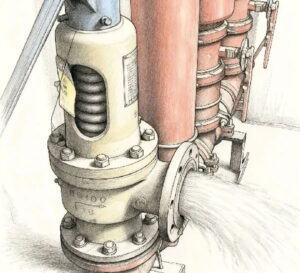

Check valves are primarily employed for equipment protection and system integrity. They are typically installed at:

Pump or Compressor Discharge: To prevent high-pressure fluid from flowing back and damaging the equipment upon shutdown.

Parallel Systems: To prevent media from a high-pressure line from migrating into a low-pressure line.

Part III: Comprehensive Comparison Table: Ball Valve vs Check Valve

| Characteristic | Ball Valve | Check Valve |

| Primary Function | Active Isolation, Shut-off (On/Off control) | Passive Protection, Prevents backflow (Unidirectional control) |

| Control Method | Active Control (Manual, Electric, or Pneumatic Actuator) | Passive Control (Automatic operation based on fluid pressure) |

| Operation | Requires external input (e.g., 90° turn) | Fully automatic, no external input required |

| Throttling Ability | Poor (Causes wear and damage) | None (Purely ON/OFF based on flow direction) |

| Flow Direction | Bi-directional (Flows in either direction when open) | Uni-directional (Prevents reverse flow) |

| Typical Materials | Stainless Steel, Carbon Steel, Brass, PVC, PFA-lined | Stainless Steel, Carbon Steel, Bronze, Composites |

| Common Media Use | Gases, Clean Liquids, High-pressure service. | Liquids, Gases, Vapors (Used to prevent column separation) |

| Application Role | Isolation Valve, Process Control Valve | Protection Valve, Non-return Valve |

Part IV: Advanced Comparison: Swing Check Valve vs. Ball Check Valve (Long-Tail Focus)

Within the family of check valves, the selection between the main types depends on the specific flow conditions and cleanliness of the medium.

| Feature | Swing Check Valve | Ball Check Valve |

| Closing Mechanism | A hinged disc swings onto the seat. | A ball (free-floating or spring-loaded) rests on the seat ring. |

| Flow Resistance | Very Low (Full, unobstructed flow path when open). | Moderate (Ball slightly obstructs the flow path). |

| Best For | Systems with Gate Valves, low-pressure drop systems, and large diameters. | Viscous fluids, lines with residue, vertical flow installations. |

| Limitation | Cannot be used in pulsing flow systems; constant flapping can cause damage. | The ball may vibrate at high flow rates if not spring-loaded. |

Part V: System Integration and Synergy – Using Them Together

Ball valves and check valves are complementary and mutually indispensable in fluid systems. They work together to ensure both operational flexibility and safety.

The Classic Setup: Pump Discharge Piping Diagram

In any pumping system, the correct placement of these two valves is critical:

The Check Valve (Adjacent to the Pump): Its role is to protect the pump. It prevents instantaneous backflow from the discharge line, which could damage the impeller or cause water hammer upon shutdown.

The Ball Valve (Downstream of the Check Valve): Its role is isolation for maintenance. When the pump or check valve requires service, the ball valve can be manually closed to isolate the system fluid, preventing leakage.

Critical Understanding: A Ball Valve can never replace a Check Valve. A ball valve is actively operated and cannot automatically respond to sudden or unexpected changes in fluid pressure.

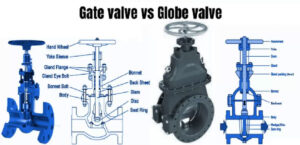

Part VI: The Engineer’s Guide: How and When to Choose

One must first determine the valve’s purpose before selection: Is it for active control or passive safety?

| System Requirement/Scenario | The Right Choice | Primary Reason |

| Emergency Shut-off | Ball Valve | Fast 90° actuation and superior sealing. |

| Preventing System Backflow | Check Valve | Automatic, pressure-differential operation provides safety barrier. |

| High-Volume Isolation (ON/OFF) | Ball Valve | Low pressure drop when open and quick operation. |

| Handling Slurry/Residue | Ball Check Valve | The continuous motion of the ball helps keep the seat clean. |

| Need for Flow Control/Throttling | Neither | Use a Globe Valve instead. Ball and Check Valves are for ON/OFF service. |

Selection and Maintenance Focus

Ball Valve Focus: Ensure the seal material (e.g., PTFE) is compatible with media temperature and chemical properties.

Check Valve Focus: Select the correct type to minimize headloss and water hammer risk. Always follow the flow direction arrow marked on the body.

Conclusion

Ball valves and check valves are the “right and left hands” of a fluid control system: The ball valve provides operational flexibility, and the check valve ensures running safety. By understanding their distinct mechanisms and applying the correct valve for the job, you ensure the longevity and efficiency of your piping network.

Contact a reliable valve supplier to acquire the right valves for your business necessities.