In massive industrial operations, urban development projects, and essential water management systems, the flow of fluids—whether liquid, gas, or slurry—is the lifeblood. The reliability of this system rests on four pillars: Valves, Pumps, Piping, and Fittings.

A simple misunderstanding of technical terms can lead to serious mistakes, ranging from selecting an inefficient pump to catastrophic safety incidents. This guide is crafted by experienced engineering professionals to provide a clear, practical, and authoritative breakdown of the core terminology you must know.

Table of Contents

ToggleI. Essential Terminology for Valves: The Flow Controllers

Valves are more than just “on/off” switches; they are the precision instruments that manage, protect, and regulate fluid media.

(A) Valve Fundamentals: Understanding the Numbers

| Term | Simple Definition | Why it Matters (Practical Value) |

| Nominal Diameter (DN) | The standard size for connecting the valve to the pipe (e.g., DN100). | Standardization. Ensures you buy the correct pipe fittings and flanges. (Note: This is a reference number, not the exact inner diameter.) |

| Nominal Pressure (PN) | The maximum rated pressure the valve can safely handle at a reference temperature. | Safety First. Must match the pressure of your piping system (e.g., PN40 is rated for 40 bar or approx. 4 MPa). |

| Operating Temperature | The temperature range where the valve materials (especially seats and seals) remain functional. | Material Selection. Plastics (PTFE) fail at high heat; stainless steel is required for steam/extreme cold. |

| Leakage Class | Measures how tightly a valve seals when closed (e.g., Class IV to Class VI). | Process Integrity. Class VI is essential for toxic, expensive, or zero-leak services. (Referenced by ANSI/FCI 70-2 standards). |

| Flow Coefficient (Cv/Kv) | A measure of the valve’s capacity to pass fluid. Higher numbers mean less flow resistance. | Sizing Accuracy. Crucial for control valves; used by engineers to ensure the valve can handle the required flow rate range. ( Cv is GPM at 1 psi drop; Kv is m³/h at 1 bar drop). |

(B) Valve Types: A Practical Overview

Understanding valve function prevents disastrous selection errors:

| Valve Type | Primary Function | Ideal Use Case | Avoid Use Case |

| Gate Valve | Isolation (On/Off). Provides a clear, unobstructed path. | Main pipeline shut-off in large diameter, low-cycling lines. | Never for throttling (partially open flow). Causes rapid damage. |

| Ball Valve | Isolation (Quick On/Off). Uses a 90° rotating ball. | Systems requiring fast operation, tight shut-off, and low flow resistance. | High-pressure steam or highly abrasive slurries (can erode the seal). |

| Globe Valve | Regulation/Throttling. Uses a disc that moves along the flow line. | Precision flow control in steam and high-pressure lines. | Where minimal pressure drop is required (it causes significant resistance). |

| Butterfly Valve | Isolation/Semi-Throttling. Uses a rotating disc (plate). | Large diameter, low-to-medium pressure systems (e.g., water, air, HVAC). | High-pressure, high-temperature service where bubble-tight shut-off is critical. |

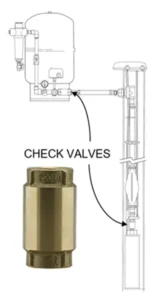

| Check Valve | Safety/Backflow Prevention. Automatic, passive protection. | Downstream of pumps/compressors to prevent fluid reversal and water hammer. | Never rely on it for isolation (it may leak slowly). |

(C) The Actuation Method: Who’s in Control?

Manual Valve: Hand-operated (handwheel, lever). Practical Use: Low-frequency operation, small sizes, or local emergency shut-off points.

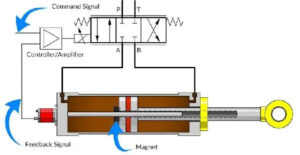

Electric Valve: Uses an electric motor/actuator. Practical Use: Remote control, slow precise regulation, and integration into automated systems.

Pneumatic Valve: Uses compressed air. Practical Use: Fast-acting isolation and areas requiring explosion-proof safety (common in Chemical/Oil & Gas).

II. Essential Terminology for Pumps: The System Heart

Pumps convert mechanical energy into fluid energy. Correct sizing is paramount to system efficiency and avoiding equipment failure.

(A) Pump Fundamentals: Getting the Flow Right

Flow Rate (Q): How much liquid the pump moves per unit time (m³/h or L/s). Practical Use: Must match the demand of the system.

Head (H): The vertical distance (in meters) or equivalent pressure the pump can lift the fluid. Practical Use: The most critical selection parameter. It defines the pump’s pressure capacity against all system resistances (friction, elevation).

Net Positive Suction Head (NPSH): The pressure required at the pump inlet to prevent Cavitation (destructive formation and collapse of vapor bubbles).

NPSHr (Required): The pressure the pump needs.

NPSHa (Available): The pressure the system provides.

Quick Engineering Tip: Always ensure NPSHa is greater than NPSHr by a safety margin (+0.5m minimum) to protect your impeller.

Efficiency (eta): The ratio of fluid power output to shaft power input. Practical Use: Directly impacts operating costs. A pump running at 60\% efficiency wastes 40\% of the energy it consumes.

(B) Pump Types: Selecting the Right Mechanism

| Pump Type | Working Principle | Best For | Application Risk |

| Centrifugal Pump | Uses centrifugal force from impeller rotation. | High flow rate, low viscosity (e.g., water, light oil). Most common type. | Must prevent Cavitation and Dry Running. |

| Positive Displacement (PD) Pump | Traps a fixed volume of fluid and physically forces it through. | High head, low flow rate, high viscosity (e.g., thick oil, sludge, metering chemicals). | Must never be run against a closed discharge valve (causes pressure spike/burst). |

| Axial/Mixed Flow Pump | Uses propeller-like action (axial) or combined flow (mixed). | Very high flow rate, very low head (e.g., flood control, irrigation). | High risk of energy waste if system conditions vary widely. |

III. Essential Terminology for Piping Systems: The Transport Backbone

Piping connects everything, but its terminology focuses on size and pressure rating, which are crucial for material strength.

(A) Piping Fundamentals: Size and Strength

Nominal Diameter (DN): Same as the valve: the standard reference size.

Outer Diameter (OD) & Inner Diameter (ID): Practical Use: You need OD for selecting clamps and hangers, and ID for fluid velocity calculations.

Wall Thickness (WT): The thickness of the pipe material. Practical Use: Directly determines the pipe’s pressure rating and resistance to corrosion/abrasion.

Design Pressure: The maximum pressure the pipe is engineered to withstand (typically higher than the normal Working Pressure). Quick Engineering Tip: Always design systems using the Design Pressure to account for surges and abnormal conditions.

(B) Piping Materials: Choosing Your Transport

| Material Type | Key Advantage | Typical Application |

| Steel Pipe (Carbon/Stainless) | High strength, high-pressure, high-temperature tolerance. | Oil & Gas, high-pressure steam, industrial process lines. |

| Ductile Iron Pipe | High durability, good corrosion resistance, low cost. | Urban water supply, sewage, underground service lines. |

| Plastic Pipe (PE, PVC, PPR) | Excellent corrosion resistance, lightweight, low cost, easy install. | Residential plumbing, chemical drainage, non-pressure applications. |

IV. Core Terminology for Pipe Fittings: The Connectors

Fittings are the components that join pipes, change direction, or provide service access.

| Fitting Term | Function | Connection Type | Practical Insight |

| Elbow (90°, 445°) | Changes pipe direction. | Welded, Threaded, Flanged. | Long Radius Elbows (R=1.5 DN) reduce friction loss more than short radius ones (R=1.0 DN). |

| Tee/Cross | Creates branches (3-way or 4-way split). | Welded, Threaded, Flanged. | Use Reducing Tees to match the branch pipe diameter to the required flow. |

| Reducer | Connects pipes of different diameters. | Welded, Flanged. | Eccentric Reducers are used on the bottom of a horizontal pipe to avoid pockets of trapped air or liquid. |

| Flange | A detachable connection that bolts pipes, valves, and equipment together. | Bolted connection (requires Gasket). | Essential for maintenance access. Use Weld Neck Flanges for high pressure/temperature service. |

| Union | A small, threaded fitting that allows easy manual separation of pipes. | Threaded. | Use on utility lines before valves that may need regular removal/repair. |

| Expansion Joint | Absorbs movement (thermal expansion/contraction) in the pipe run. | Welded, Flanged. | Crucial in long, hot pipelines to prevent excessive stress and pipe failure. |

V. Critical Industry Terms for System Safety and Longevity

These terms define the challenges and solutions in fluid handling:

Flow Resistance: The overall opposition to flow in the system. Goal: Minimize this by using larger pipes and low-resistance valves (like Ball/Gate).

Cavitation: The destructive process of vapor bubbles collapsing near metal surfaces (pumps/valves) due to low pressure. Practical Risk: Can destroy an impeller in months.

Corrosion: Chemical or electrochemical attack on materials (e.g., rusting). Mitigation: Use stainless steel, FRP (Fiberglass), or protective linings based on the fluid’s $\text{pH}$.

Wear (Abrasion): Physical damage caused by solid particles (sand, slurry) in the fluid. Mitigation: Select valves and pumps with specialized hardened trim or ceramic coatings.

Leakage (Internal/External): Loss of media. Practical Risk: Internal leakage (across a closed valve seat) wastes energy and risks contamination. External leakage is a safety/environmental hazard.

Selection (Sizing): The process of matching the correct valve, pump, and pipe size to the specific operational requirements (pressure, flow, media). Expert Insight: Oversizing is as bad as undersizing—it wastes capital and reduces efficiency.

Applied Terminology: Real-World Systems

Urban Water Supply: Relies on high-efficiency Centrifugal Pumps, large-diameter Ductile Iron Pipes, and simple Gate/Butterfly Valves.

Oil & Gas Transmission: Characterized by extremely high Design Pressure, Welded Fittings, and Stainless Steel/Alloy Steel pipe and valves to handle corrosive hydrocarbons.

HVAC Systems: Focuses on energy efficiency and low noise, often utilizing Copper Pipe, PPR, and small, automated Control Valves.

Fire Protection System: Requires Grooved/Clamp Fittings (for seismic stability) and highly reliable, code-compliant Fire Pumps and Check Valves.