The ball valve is one of the most widely used valve types in industrial piping systems, valued for its simple operation, reliable sealing, and broad application range. Due to diverse structural characteristics and application demands, ball valves have evolved into numerous configurations. Understanding these structural forms is crucial for correct selection and optimal system performance.

This comprehensive guide analyzes the various structural forms of ball valves, providing essential knowledge for industrial professionals.

Table of Contents

Toggle1. Ball Valve Structure Classification Overview

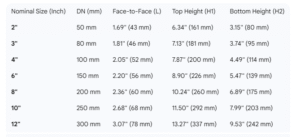

| Classification Type | Key Structures |

| By Ball Support | Floating Ball Valve, Trunnion Mounted Ball Valve, Elastic Ball Valve |

| By Body Structure | One-Piece Body, Two-Piece Body, Three-Piece Body, Top-Entry Ball Valve |

| By Bore Type | Full Bore (Full Port), Reduced Bore (Reduced Port), V-Port Ball Valve, Multi-Port Ball Valve |

| By Connection Type | Flanged, Threaded (Screwed), Wafer/Lug, Welded (BW/SW) |

| By Functional Feature | Fire Safe, Anti-Static, Jacketed (Insulated), Cryogenic |

2. Classification by Ball Support Mechanism

2.1 Floating Ball Valve (Most Common)

Structure: The ball is “floating” within the valve cavity and is connected only to the stem, lacking a fixed support trunnion.

Working Principle: Process pressure pushes the ball against the downstream seat ring, creating contact stress for sealing.

Pros & Cons: Simple structure, lower cost, compact size. However, the operating torque is higher, limiting its use in large diameters and high-pressure service.

Application: General industrial use (water, air, oil), civil engineering, and small to medium bore sizes (DN15–DN200).

2.2 Trunnion Mounted Ball Valve (Fixed Ball Valve)

Structure: The ball is supported by upper and lower trunnions (fixed shafts) within the valve body. The ball can only rotate, not move laterally.

Working Principle: Sealing relies on springs or process pressure pushing the valve seats toward the fixed ball. Allows for double block and bleed (DBB) capabilities.

Pros & Cons: Low operating torque (less friction), ideal for large diameter and high pressure, reliable bi-directional sealing. More complex and costly structure.

Application: Petrochemical industry, high-pressure and high-temperature service, long-distance pipelines, and large bore sizes (DN200+).

3. Classification by Body Structure

3.1 Three-Piece Body Ball Valve (Common for Maintenance)

Structure: The valve body consists of three parts: two end connectors and a central body section, held together by bolts.

Advantage: Extremely easy to service—the central body can be removed for maintenance (e.g., seal replacement) without fully removing the end connections from the pipeline (in-line repair).

Application: Services requiring frequent maintenance, cleaning, or sterilization (e.g., food, pharmaceutical industries).

3.2 Top-Entry Ball Valve

Structure: The ball and all internal components are installed and secured from the top of the valve body via a bolted cover (bonnet).

Advantage: True in-line repair capabilities without breaking the main flange connections.

Application: Underground pipelines, space-constrained areas where removal is impractical, and critical services.

4. Classification by Bore and Flow Path

4.1 Full Bore Ball Valve (Full Port)

Structure: The ball bore diameter is equal to the pipeline’s inner diameter.

Advantage: Minimal fluid resistance (low pressure drop), non-restrictive flow.

Application: Pigging operations (cleaning pipelines), slurry media, and systems where minimizing pressure loss is critical.

4.2 Reduced Bore Ball Valve (Reduced Port)

Structure: The ball bore diameter is smaller than the pipeline’s inner diameter.

Advantage: More compact structure, lower cost, and reduced torque.

Application: General media where flow capacity is not the absolute priority, cost-sensitive applications, and space-limited installations.

4.3 V-Port Ball Valve

Structure: The ball or seat has a V-shaped notch or opening.

Advantage: Provides inherent throttling or modulating capability, allowing for precise flow regulation. The sharp edge helps shear through fibers or semi-solids.

Application: Flow control circuits, throttling service, and handling fibrous or high-viscosity media.

5. Classification by Connection and Function

5.1 By Connection Type

| Connection Type | Application | Key Characteristic |

| Flanged | Most common for industrial, high-pressure, large-bore piping. | Secure, bolted connection to mating pipe flanges. |

| Welded (BW/SW) | Critical service (hazardous media), zero-leakage required, high pressure/temperature. | Permanent, leak-proof connection to the pipe. |

| Wafer/Lug | Space-constrained installations, lightweight assemblies. | Clamped between two pipe flanges using through-bolts. |

5.2 By Functional Feature

Fire Safe Ball Valve: Designed with secondary metal-to-metal seating that seals if the primary soft seats are burned away in a fire, maintaining isolation. Essential for flammable fluid services (API 607/API 6FA standards).

Anti-Static Ball Valve: Includes a spring-loaded path to electrically bond the ball, stem, and body, preventing the build-up of static electricity that could ignite flammable media.

Cryogenic Ball Valve: Features extended bonnets to keep the stem packing away from the cryogenic temperatures (e.g., -196°C for LN2), preventing seal freeze-up and ensuring operability.

6. Ball Valve Selection Guide

The correct selection always hinges on a balance of technical requirements and cost.

| Factor | Condition | Recommended Structure | Rationale |

| Pressure/Diameter | High Pressure (PN100+), Large Bore (DN200+) | Trunnion Mounted | Lower torque, higher sealing force stability. |

| Flow Control | Throttling or Regulating Flow Rate | V-Port Ball Valve | Provides precise, repeatable control characteristics. |

| Maintenance | Frequent Repair or In-Line Service Required | Three-Piece Body or Top-Entry | Allows quick access to internals without line breakdown. |

| Safety | Flammable or Explosive Medium | Fire Safe & Anti-Static | Essential regulatory compliance for safety and static discharge. |

| Resistance | Minimize Pressure Drop | Full Bore Ball Valve | Eliminates flow restriction and energy loss. |

As a piping and instrumentation professional, mastering these structural forms is fundamental to making informed, reliable, and cost-effective valve selection decisions for critical industrial systems.