A flow control valve is one of the most critical components in any fluid power or process system. Unlike simple on/off valves, these devices are specifically designed to regulate the rate of fluid movement, which in turn controls the speed and performance of the entire system.

Understanding the definition, function, and mechanics of these valves is fundamental to successful system design and maintenance.

Table of Contents

Toggle1. Defining the Flow Control Valve

1.1 What is a Flow Control Valve?

A flow control valve is a mechanical device used to regulate the flow rate of a liquid or gas through a piping system or fluid power circuit. By creating a variable restriction in the fluid path, it manages the volume of fluid passing through a given point per unit of time (e.g., liters per minute or gallons per minute).

Flow Control Valve Definition: A valve whose primary function is to maintain or adjust the rate of fluid flow, often to control the speed of an actuator (cylinder or motor) or to balance a process line.

1.2 What Does a Flow Control Valve Do?

The core purpose of a flow control valve is to modulate system output. In industrial machinery, this translates directly to:

Speed Control: In hydraulic and pneumatic systems, the flow rate controls the speed at which a cylinder extends or a motor rotates.

Balancing: In large piping networks (like HVAC or water distribution), flow control valves ensure that each branch receives the correct, non-excessive volume of fluid.

Sequencing: Controlling the flow can be used to manage the timing and order of operations within an automated cycle.

2. The Core Working Principle: Variable Restriction

How Does a Flow Control Valve Work?

All flow control valves function based on the principle of creating a pressure drop across a controlled orifice.

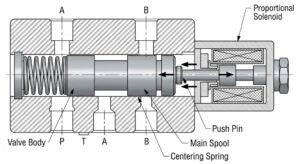

Restriction: The valve contains a mechanism (like a needle, spool, or gate) that can be adjusted to narrow the internal flow path.

Pressure Drop: According to Bernoulli’s principle, when the fluid passes through this restricted area (orifice), its velocity increases, and its pressure drops.

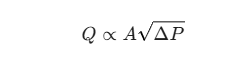

Flow Regulation: Since the flow rate (Q) is proportional to the size of the orifice and the square root of the pressure drop (∆P), adjusting the orifice size directly controls $Q$.

3. Key Types of Flow Control Valves

Flow control valves are primarily categorized by the mechanism they use to achieve restriction and whether they compensate for changes in system pressure.

3.1 Non-Compensated (Fixed) Flow Control Valves

These are the simplest types. They set a fixed flow area, but their actual flow rate will change if the system pressure or load changes.

Needle Valve: Uses a finely tapered stem (needle) that enters a matching orifice. Turning the handle allows for highly precise, gradual adjustment of the flow area. They are excellent for fine metering.

Gate and Globe Valves: While primarily used for isolation, Globe valves can be used for rough flow regulation because their stem movement is proportional to the opening area.

3.2 Compensated Flow Control Valves (The Standard for Hydraulics)

These valves are essential in hydraulic systems where load changes are common (e.g., a cylinder lifting a heavy load, then a light load).

Pressure-Compensated Flow Control Valve: This valve includes an automatic compensator (usually a spring-loaded spool) that maintains a constant pressure drop ($\Delta P$) across the main adjustable orifice, regardless of upstream or downstream pressure fluctuations.

Result: The flow rate ($Q$) remains nearly constant, ensuring consistent speed even if the load on the actuator changes. This is the definition of reliable hydraulic speed control.

Temperature-Compensated Flow Control Valve: These include an element that adjusts the orifice size to counteract changes in fluid viscosity caused by temperature variations, maintaining a more accurate flow rate.

4. Flow Control in Fluid Power: Hydraulic Fundamentals

The term flow control valve hydraulic refers specifically to the use of these devices to manage speed in a hydraulic circuit.

Hydraulic Speed Control

In hydraulics, flow control valves are often classified by where they are placed relative to the actuator:

Meter-In Circuit: The valve controls the flow into the actuator.

Meter-Out Circuit: The valve controls the flow exiting the actuator (best for controlling compressive or opposing loads).

Bleed-Off Circuit: The valve diverts excess flow directly back to the tank, regulating the flow that remains to power the actuator.

Schematic Symbols

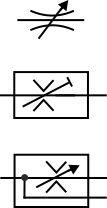

In engineering drawings, flow control valves are represented by standard symbols:

Basic Flow Control: A square with a horizontal line and an oblique arrow passing through the line (indicating variable restriction).

Pressure Compensated: Includes an internal compensating spool symbol, often denoted by a horizontal line with a diagonal arrow above a small block, indicating the constant pressure drop function.

For more detailed applications, including specific designs for water systems and a deep dive into hydraulic circuit diagrams, please refer to our guide on “Flow Control Valve Applications & Symbols.“