Table of Contents

ToggleIntroduction: From Symbol to Specification

Understanding the L-Port vs. T-Port flow pattern is crucial, but successful process design requires selecting the right type, size, and material for your specific application. Choosing incorrectly can lead to inefficient flow, temperature instability, or premature valve failure.

This guide focuses on the practical criteria for selecting 3-Way valves, with a special emphasis on common fluid and HVAC system requirements.

I. Selecting the Right 3-Way Valve Type

The valve type determines performance characteristics such as pressure drop, sealing quality, and maintenance needs.

1. 3-Way Ball Valves (Isolation and Diverting)

Primary Function: Excellent for quick switching and isolation. They offer tight shut-off and minimal pressure drop (high Cv) due to their full port capabilities.

Best For: Simple on/off switching, general process applications, and non-slurry systems.

Limitation: Poor for fine flow modulation or throttling, as partial opening can lead to high velocity and seat erosion.

2. 3-Way Globe Valves (Mixing and Regulating)

Primary Function: Designed specifically for flow regulation and mixing. The internal seat and plug design allow for precise control of the flow ratio between the two inlet ports.

Best For: HVAC Temperature Control (blending hot and cold water), chemical blending, and any application requiring proportional control.

Limitation: Higher pressure drop (lower Cv) compared to Ball Valves, and typically higher cost.

3. Specialized 3-Way Valve Types

Plug Valves: A robust choice for sludges, slurries, or high-temperature applications where the wiping action cleans the sealing surfaces.

Butterfly Valves: Used primarily for very large pipe sizes (4″ and above) where a lightweight and compact 3-Way solution is needed.

II. Common Applications: 3-Way Valves in Fluid Systems

3-Way valves are indispensable in fluid handling, particularly in controlling temperatures and fluid routes.

A. HVAC Zoning and Temperature Control

Function: Used in commercial heating and cooling systems to mix chilled water and return water (or hot water) to maintain a precise temperature in a specific zone or coil.

Recommended Valve: 3-Way Globe Valves (mixing type).

Flow Pattern: T-Port is commonly used to blend two streams into a single outlet temperature.

B. Boiler Bypass and Recirculation

Function: Used to maintain minimum flow through a boiler or heating element by diverting excess hot fluid back into the return line. This protects the equipment.

Recommended Valve: 3-Way Ball Valve or robust 3-Way Plug Valve.

Flow Pattern: L-Port is ideal for this simple diverting (switching) function.

III. Critical Selection Criteria: Size and Material

1. Sizing: Beyond Pipe Diameter

Correct sizing is the single most critical factor for valve performance. Never size a valve based on pipe diameter alone.

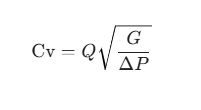

- The Cv Value: The valve must be sized using the Flow Coefficient (Cv), which relates the flow rate, fluid gravity, and pressure drop.

Cv Value Q = Flow Rate (GPM)

G = Specific Gravity of Fluid

∆P = Allowable Pressure Drop (PSI)

Impact of Error: An oversized valve will operate at the very bottom of its stroke, leading to poor control and increased wear; an undersized valve will restrict flow and consume excess energy.

2. Material Selection

The valve material must be compatible with the fluid, temperature, and pressure rating of the system.

| Material | Key Advantage | Typical Applications |

| Brass/Bronze | Cost-effective, general corrosion resistance. | Potable water, low-pressure air, heating systems. |

| Stainless Steel (304/316) | High corrosion resistance, high temperature and pressure. | Chemicals, food processing, high-pressure steam, harsh environments. |

| PVC/Plastics | Excellent chemical resistance. | Acid/base transfer, low-pressure corrosive service. |

IV. Summary and Decision Matrix

| Your Goal | Recommended 3-Way Valve Type | Preferred Flow Pattern | Key Criteria |

| Precise Temperature Mixing | Globe Valve | T-Port | Modulating Control and Cv calculation. |

| Simple Switching/Diverting | Ball Valve | L-Port | Tight Shut-off and high Cv. |

| Handling Slurry/Abrasives | Plug or Pinch Valve | L-Port or T-Port | Material resistance and self-cleaning ability. |