Table of Contents

ToggleIntroduction: Why Ball Valve Design Matters

Ball valves are the preferred choice for reliable, quick ON/OFF isolation in piping systems. While they share the same quarter-turn function, the internal mechanism that supports the ball—known as the Trunnion or Floating design—fundamentally dictates the valve’s pressure capacity, size limit, and operational torque.

Choosing between a Floating and a Trunnion mounted ball valve is the first critical step for any high-performance application.

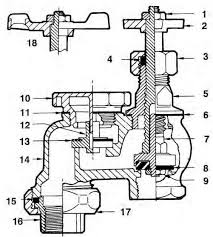

I. Floating Ball Valve: Design and Principle

The Floating Ball Valve is the most common and economical design, typically used in smaller pipelines and lower pressure services.

1. Working Principle

In a floating design, the ball is suspended (or “floats”) within the valve cavity and is held in place solely by the two seat rings (upstream and downstream) and the stem.

Sealing Mechanism: When the valve is closed, the upstream pressure pushes the ball against the downstream seat ring. This pressure-assisted mechanism ensures a tight seal.

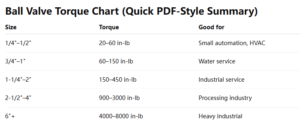

Pressure Limit: As line pressure increases, the force exerted on the downstream seat increases. This limits the size and pressure rating of floating valves, as excessive force can deform the seat and increase operational torque.

2. Key Characteristics

| Feature | Description |

| Size Range | Typically used for smaller lines (up to 6inches). |

| Pressure | Suited for low to medium-pressure applications. |

| Torque | Operational torque increases proportionally with line pressure. |

| Cost | Generally more economical and simpler to manufacture. |

II. Trunnion Mounted Ball Valve: Design and Principle

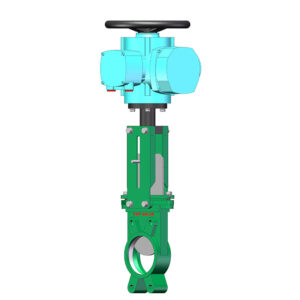

The Trunnion Mounted Ball Valve is the heavy-duty solution, designed for high-pressure, high-volume, and large-diameter pipelines.

1. Working Principle

In a trunnion design, the ball is mechanically anchored. It features an additional stem-like component (the Trunnion) at the bottom, which absorbs the pressure thrust.

Support Structure: The ball is supported by the stem at the top and the trunnion at the bottom. This mechanical support prevents the ball from floating.

Sealing Mechanism: Since the ball is fixed, the line pressure pushes the seat rings against the ball. This arrangement allows the sealing force to be independent of the line pressure thrust.

Pressure Limit: The mechanical support means the valve can handle much higher pressure and larger sizes without excessive torque or seat deformation.

2. Key Characteristics

| Feature | Description |

| Size Range | Ideal for large pipelines (over 6 inches) and very large diameters. |

| Pressure | Used for high-pressure and high-temperature services (e.g., API 6A, API 6D). |

| Torque | Operational torque is relatively constant, regardless of line pressure. |

| Cost | Higher manufacturing complexity and cost. |

Most Trunnion Mounted Ball Valves feature Double Block and Bleed (DBB) capability. Because both seats are independent and spring-loaded, the valve can seal both the upstream and downstream sides simultaneously. This allows operators to bleed off pressure from the body cavity to verify seal integrity—a critical safety requirement in Oil & Gas.

“Trunnion valves often include Self-Relieving Seats. When the pressure in the valve cavity exceeds the spring tension, the seats slightly back away from the ball to release excess pressure into the pipeline, preventing body damage.”

III. Core Comparison: Trunnion vs Floating Ball Valve

Understanding the differences in force distribution is the key to selection.

| Characteristic | Floating Ball Valve | Trunnion Mounted Ball Valve |

| Ball Support | Supported only by the seats (it “floats”). | Supported by the stem (top) and trunnion (bottom). |

| Sealing Force | Pressure pushes the ball onto the seat. | Pressure pushes the seat onto the ball. |

| Pressure Thrust | Fully transferred to the downstream seat. | Absorbed by the trunnion shaft. |

| Operational Torque | Increases significantly with pressure and size. | Low and Constant, independent of pressure. |

| Application | Utility lines, general chemicals, low-pressure gas. | Oil & Gas pipelines, high-pressure processing, large diameters. |

| Cost | Lower | Higher |

IV. The Engineer’s Selection Guide

The choice between the two designs should be driven by three primary factors:

1. Pressure and Size

For services below 6 inches and with standard pressure ratings (ANSI Class 150 to 300), the Floating Ball Valve is the cost-effective choice.

For high-pressure systems (ANSI Class 600 and above) or large sizes (6inches and up), the Trunnion Mounted Valve is mandatory due to the lower, more predictable operating torque.

2. Torque and Actuation

If the valve must be operated by a smaller, cost-effective actuator (electric or pneumatic), the Trunnion design is preferred because its stable, lower torque reduces actuator size and cost.

3. Maintenance Considerations (Top Entry)

Both designs can be offered as Top Entry Ball Valves. This allows the ball and internals to be serviced by removing the bonnet from the top, without needing to remove the entire valve body from the pipeline. This is a common feature for critical service Trunnion valves.

The “Total Cost” Secret

Many buyers choose a Floating Ball Valve to save money on the unit price. However, as the pipe size grows, the operational torque of a floating design sky-rockets.

Floating: High torque → Huge Actuator → High Total Cost.

Trunnion: Low, Constant torque → Small Actuator → Better Long-term Value.

Don’t just look at the valve price. A 10-inch Floating Ball Valve requires a massive, expensive actuator due to its high torque. A 10-inch Trunnion valve, despite being pricier, can use a much smaller actuator. Often, the total package cost (Valve + Actuator) is lower for the Trunnion design.