Table of Contents

ToggleWhy Valves Leak and Why It Matters

Valve leakage is one of the most common and critical maintenance issues in any fluid system. Leaks not only represent product loss and inefficiency but also pose serious safety and environmental hazards, particularly in high-pressure or hydrocarbon service.

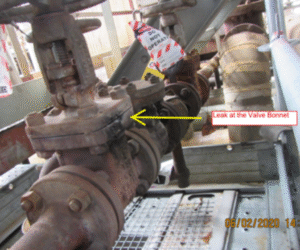

The majority of external valve leaks originate from two key pressure boundaries in the upper assembly: the valve bonnet joint and the valve stem (packing area). This guide provides a focused approach to diagnosing and resolving these common issues.

I. Source 1: Valve Stem Leakage (Packing Failure)

The most frequent source of leakage in manual valves (like the Gate Valve) is the seal around the moving stem, often searched as gate valve leaking at stem or leaking gate valve stem. This is known as a valve packing leak.

Causes of a Valve Packing Leak

Packing Compression Loss: Over time and usage, the packing material (e.g., graphite, PTFE) hardens or loses elasticity, resulting in insufficient pressure against the valve stem.

Improper Gland Load: The bolts securing the packing gland (follower) may be overtightened (crushing the packing) or, more commonly, undertightened (allowing fluid escape).

Stem Damage: Pitting, scoring, or corrosion on the valve stem creates pathways for fluid bypass.

Temperature Cycling: Frequent temperature changes can cause the packing material to expand and contract, eventually degrading the seal.

Diagnosis and Repair (Water Valve Leak Repair Focus)

If you observe gate valve leaking from stem (or any multi-turn valve):

Initial Check (Tightening): First, attempt to slightly and evenly tighten the nuts on the packing gland bolts (the bolts on the top of the bonnet). Caution: Do not overtighten, as this can impede valve operation.

Packing Replacement: If tightening fails, the packing material must be replaced.

Procedure: Fully isolate and depressurize the line. Open the valve fully (raising the back seat). Remove the packing follower, extract the old rings, clean the stuffing box, and insert new packing rings in staggered sets, ensuring proper seating before retightening the gland evenly.

Maintenance Insight: Addressing a valve packing leak promptly preserves the integrity of the stem and prevents accelerated component corrosion.

II. Source 2: Valve Bonnet Leakage (Gasket Failure)

A valve bonnet leak is leakage occurring where the bonnet plate meets the valve body. This is a failure of the static seal created by the joint gasket.

Causes of a Valve Bonnet Leak

Gasket Failure: The bonnet gasket material may have chemically degraded, extruded due to high pressure, or simply aged beyond its lifespan.

Insufficient Pre-load: The most common cause is the loss of bolt tension. Thermal cycling (heating and cooling) causes the bonnet bolts to relax, leading to bolted bonnet leakage.

Flange Surface Damage: Scratches, nicks, or corrosion on the sealing faces of the body or bonnet prevent the gasket from seating properly.

Diagnosis and Repair

If you suspect a valve bonnet leak at the body joint:

Bolt Tensioning: For a bolted bonnet, a slight, even retorquing of the flange bolts (following manufacturer specifications) can often reseal the joint.

Gasket Replacement: If retorquing fails, the line must be shut down and depressurized completely for a bonnet gasket replacement.

Procedure: Remove all bonnet bolts, lift the bonnet, replace the old gasket with a new one of the correct material and thickness, and reassemble using a controlled torquing pattern to ensure even pressure distribution.

III. Addressing Gate Valve Leaks (Specific Example)

Gate valve leaks are often noticeable because the long rising stem makes the leakage point highly visible. In domestic contexts (water valve leak repair), these are often found on older, simpler screwed bonnet designs.

When a gate valve is leaking at the stem, it signals a failure in the packing area located directly beneath the handle.

Actionable Step: Always confirm the leak location. If the leak is between the body and the end connection, the issue is not the bonnet but the end seal (e.g., flange gasket or pipe threads).

Conclusion

External valve leakage, whether a persistent valve bonnet leak or an active valve packing leak, requires immediate attention. Proper diagnosis—identifying if the source is dynamic (stem packing) or static (bonnet gasket)—is the critical first step. Regular inspection and scheduled maintenance of the packing gland tension are the best preventive measures against costly gate valve leaks and system downtime.