Table of Contents

ToggleChoosing the Right Connection Method

In industrial piping and valve assembly, the method used to join pipes and fittings is critical to the system’s integrity, pressure rating, and longevity. Two of the most common permanent joining methods are Butt Weld (BW) and Socket Weld (SW).

While both involve welding, their structural designs and application ranges are vastly different. This guide provides a comprehensive analysis of socket weld vs butt weld to help you determine the optimal connection for your specific project.

I. Defining the Connections: What is Socket Weld and Butt Weld?

1. What is a Butt Weld (BW)?

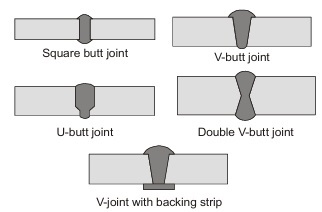

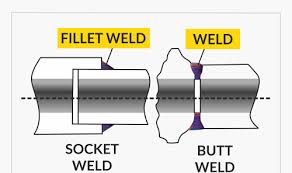

A Butt Weld is a joint where the ends of two pipes or fittings are brought together in the same plane (edge-to-edge). The ends are typically beveled to create a space for the weld metal.

Mechanism: The welder joins the two pieces by filling the groove with weld material, creating a full-penetration joint.

Keyword Insight: On engineering drawings, you will often see a specific butt weld symbol representing this seamless, high-strength connection.

2. What is a Socket Weld (SW)?

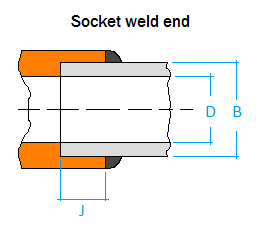

A Socket Weld involves a pipe being inserted into a recessed area of a fitting, valve, or flange.

Mechanism: Unlike BW, the weld is applied to the outside of the pipe and the fitting. This is technically a fillet weld rather than a groove weld.

Keyword Insight: Searching for what is socket welding often leads to discussions about its simplicity in alignment, as the “socket” acts as a guide.

II. Butt Weld vs. Socket Weld: Key Differences

When comparing buttweld vs socket weld, four primary factors dictate the selection:

1. Size Range and Pressure Rating

Socket Weld: Generally limited to small pipe diameters (typically 2 Inch and smaller). However, it is excellent for high-pressure classes in these small sizes.

Butt Weld: The standard for all pipe sizes, but mandatory for pipes 2 Inch and larger. It handles extreme pressures and temperatures more reliably than SW.

2. Weld Integrity and Flow Efficiency

Butt Weld: Provides a smooth internal surface with zero flow restriction. Since it is a full-penetration weld, the joint is as strong as the pipe itself.

Socket Weld: Leaves a small gap (the expansion gap) inside the fitting. This can cause turbulence and, in corrosive services, may lead to “crevice corrosion.”

3. Installation and Alignment

Socket Weld: Easier to install. The socket ensures the pipe is aligned correctly, so no temporary “tack welding” or specialized clamps are needed for alignment.

Butt Weld: Requires professional beveled ends and precise alignment by a skilled welder to ensure the weld penetrates fully and evenly.

III. Comparison Summary Table

| Feature | Butt Weld (BW) | Socket Weld (SW) |

| Connection Type | Edge-to-Edge (Groove) | Pipe into Bore (Fillet) |

| Typical Size | All sizes (Standard for >2″) | Small sizes only (≤ 2″) |

| Weld Symbol | Butt weld symbol (V-groove) | Socket weld symbol (Fillet) |

| Strength | Highest (Full penetration) | High (Fillet weld) |

| Flow Disturbance | None (Smooth bore) | Potential turbulence at the gap |

| Cost | Higher (Beveling + Skilled labor) | Lower (Faster assembly) |

IV. Technical Insight: The Critical 1/16″ Expansion Gap

In socket welding, a common mistake is pushing the pipe all the way to the bottom of the socket before welding. To meet standard engineering codes (like ASME B31.3):

A 1.6mm(1/16Inch) gap must be maintained between the pipe end and the socket bottom.

Why? This gap allows for thermal expansion during the welding process. Without it, the weld can crack as the pipe expands against the bottom of the fitting.

V. Conclusion: Which One Should You Choose?

Choose Butt Weld if: You are working with pipes larger than 2 inches, or if the system involves high temperatures, extreme pressures, or highly corrosive media where a smooth internal bore is required.

Choose Socket Weld if: You are installing small-bore piping (< 2 inches) and need a fast, cost-effective, and leak-proof connection for water, explosive gases, or hydraulic fluids.

Understanding the nuances of butt weld vs socket weld ensures that your piping system is safe, compliant, and cost-efficient.