When designing a fluid system, choosing between a Butterfly Valve and a Globe Valve is like choosing between a sprinter and a long-distance hiker. Both move through the landscape of your piping system, but they handle the terrain very differently.

One is built for speed and high-volume flow, while the other is a master of precision and control. Let’s dive into the core differences to help you decide which “athlete” belongs in your pipeline.

Table of Contents

Toggle1. The Design Philosophy: Disc vs. Plug

To understand these valves, you first need to look at how they stop the flow.

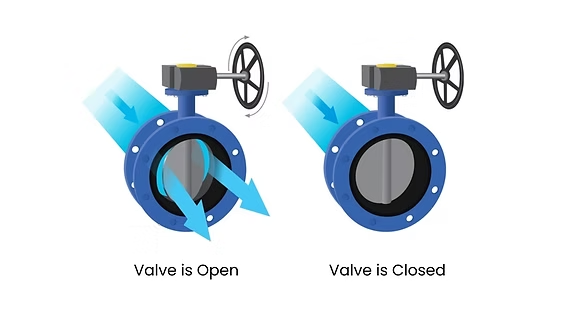

The Butterfly Valve: The Quarter-Turn Minimalist

A butterfly valve features a circular disc mounted on a rotating shaft. When the valve is open, the disc rotates 90° to sit parallel to the flow. When closed, it pivots to block the passage entirely.

Visual: Imagine a revolving door that stops exactly halfway to block the entrance.

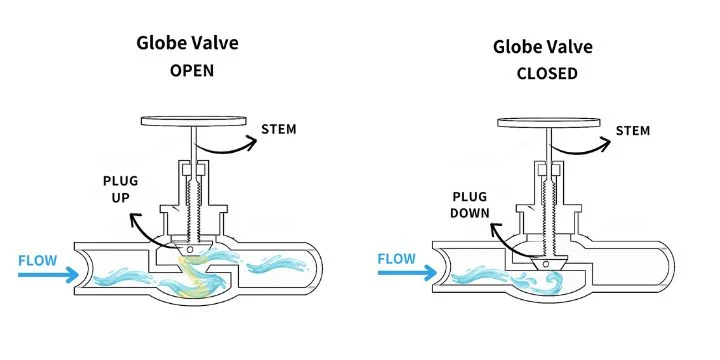

The Globe Valve: The Vertical Specialist

A globe valve gets its name from its spherical body shape. Inside, a plug (or disc) moves vertically up and down against a stationary seat. The flow must follow an “S” shaped path to get through.

Visual: Think of a water faucet in your kitchen; as you turn the handle, a stopper moves down to pinch off the flow.

2. Throttling and Control: Precision Matters

This is where the two valves drift apart most significantly.

Globe Valves are the kings of regulation. Because the plug moves slowly and linearly toward the seat, you can adjust the flow with extreme precision. If you need to keep a flow at exactly 42%, the globe valve is your best friend. They are the industry standard for throttling applications.

Butterfly Valves are built for isolation. While they can be used for basic throttling, they aren’t ideal for it. At low openings, the high-velocity flow can cause the disc to vibrate or “flutter,” leading to wear and tear. They are best used when you need to move from “Full Flow” to “Zero Flow” quickly.

3. Pressure Drop and Flow Efficiency

Energy efficiency is a major factor in modern plant design.

Butterfly Valve (High Efficiency): When open, the disc is the only thing in the way. This results in a very low pressure drop (∆P). It’s excellent for large-scale water or cooling systems where you want to keep the liquid moving with minimal resistance.

Globe Valve (Low Efficiency): Because the fluid has to make two 90° turns to get through the “S” path inside the globe, there is a significant loss of pressure. This creates a high resistance to flow, which can be a drawback in systems where pumping energy is expensive.

4. Size, Weight, and Cost

If you are working with limited space or a tight budget, the winner is usually clear.

Weight: Butterfly valves are “wafer” or “lug” style, meaning they are incredibly thin and lightweight. A 12-inch butterfly valve might weigh 50 lbs, while a 12-inch globe valve could weigh over 500 lbs.

Space: Butterfly valves take up very little “face-to-face” space in the pipeline.

Cost: For large pipe diameters (above 6 inches), butterfly valves are significantly cheaper to manufacture, ship, and install.

5. Summary Comparison Table

| Feature | Butterfly Valve | Globe Valve |

| Best Use | Quick Isolation / Large Volume | Precision Throttling / Regulation |

| Operation | Quarter-turn (90°) | Multi-turn (Linear) |

| Pressure Drop | Low | High |

| Weight/Size | Compact and Light | Bulky and Heavy |

| Maintenance | Easy to replace seats | Can be repaired in-line |

| Typical Sizes | 2″ to 100″+ | Usually < 12″ |

The Expert Verdict: Which Should You Choose?

Choose a Butterfly Valve if:

You are dealing with large-diameter pipes.

You need to save space and reduce weight.

Your main goal is to turn the flow on or off quickly with minimal pressure loss.

The budget is a primary concern.

Choose a Globe Valve if:

Precise control of flow or pressure is mandatory.

You are dealing with high-pressure steam or frequent cycling.

The pipe size is small (usually under $8\text{ inches}$).

Pressure drop is not a major concern for your system’s efficiency.