Table of Contents

ToggleWhy Steam Service Demands a Specialized Globe Valve

Steam is one of the most challenging media in industrial piping. Due to its high temperature, potential for high velocity, and the risk of “wire-drawing” (erosion), a standard utility valve will not suffice.

A dedicated Steam Globe Valve is engineered specifically to handle the unique thermodynamics of saturated and superheated steam. In this guide, we explore the critical design features that separate a high-quality steam valve from the rest.

1. The Critical Role of Hard-Faced Seating

The internal components (trim) of a globe valve for steam application are under constant attack from high-velocity vapor.

The Problem: Standard stainless steel seats can be quickly eroded by steam, a phenomenon known as “wire-drawing,” leading to internal leakage.

The Solution: Premium steam valves must feature Stellite-faced seats and discs (typically Stellite #6). This cobalt-based alloy provides exceptional hardness and resistance to thermal galling at temperatures exceeding 425°C (800°F).

2. Managing Thermal Expansion and Stem Sealing

Steam systems undergo frequent thermal cycling. As the valve heats up, the metal expands; as it cools, it contracts.

High-Temperature Packing

For steam service, Flexible Graphite is the gold standard for stem packing. Unlike PTFE, which degrades at temperatures above 250°C, graphite remains stable and maintains a bubble-tight seal even at 500°C.

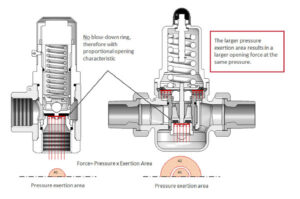

The Pressure Seal Bonnet Advantage

In high-pressure steam lines (Class 900 and above), we recommend a Pressure Seal Bonnet design. Instead of relying on bolts to combat internal pressure, the pressure seal design uses the steam’s own force to tighten the seal, preventing the common “bonnet leak” found in traditional bolted designs during thermal cycling.

3. Material Selection for Steam Service

Selecting the right body material is non-negotiable for safety and compliance with ASME B16.34.

| Steam Type | Temperature Range | Recommended Body Material |

| Saturated Steam | Up to 425°C (800°F) | ASTM A216 WCB (Carbon Steel) |

| Superheated Steam | 425°C to 540°C | ASTM A217 WC6 / WC9 (Chrome-Moly) |

| High-Temp Utility | Above 540°C | ASTM A217 C12A (Advanced Alloy) |

4. Key Design Features to Look For

When reviewing a Steam Globe Valve specification, ensure it includes these three “must-have” features:

Guided Plug Design: To prevent vibration and “chatter” in high-velocity steam flows, the plug should be guided (either top-guided or skirt-guided) to maintain perfect alignment with the seat.

Backseat Capability: An integral backseat allows the valve to be repacked while under pressure (though safety protocols usually advise doing this while the line is isolated).

OS&Y (Outside Screw and Yoke) Construction: This keeps the stem threads outside the steam flow, protecting them from corrosion and allowing for easy lubrication.

5. Maintenance: Preventing Steam Leakage

Steam leaks are expensive. A single 1/8-inch steam leak at 100psi can cost a facility thousands of dollars per year in wasted energy.

Diagnosis: Listen for a high-pitched hissing or use ultrasonic leak detection.

Prevention: Ensure the bonnet bolts are retorqued after the first few thermal cycles (the “hot torque” procedure) to account for gasket relaxation.

Conclusion: Investing in Reliability

Choosing a Steam Globe Valve is an investment in your plant’s safety and energy efficiency. By prioritizing hard-faced trims, graphite sealing, and the correct alloy materials, you can ensure a service life that spans decades rather than months.