Table of Contents

ToggleThe High Stakes of Ammonia Handling

Ammonia (NH₃) is a cornerstone of industrial refrigeration and fertilizer production, but it is also one of the most demanding media for valve design. It is toxic, corrosive to specific metals, and potentially hazardous to personnel if leaked.

When specifying a globe valve for ammonia, standard industrial valves are often disqualified. You need a solution that prioritizes material purity and absolute sealing integrity. This guide breaks down the “non-negotiables” for ammonia-rated globe valves.

1. The Gold Rule: No Copper or Brass

The most critical factor in an ammonia globe valve is the total absence of copper and its alloys (brass, bronze).

The Science: In the presence of even trace amounts of moisture, ammonia reacts with copper to cause rapid Stress Corrosion Cracking (SCC). This can lead to catastrophic valve failure in a matter of days.

Our Standard: We ensure that every component—from the valve body and disc down to the stem and small internal bushings—is constructed from Ductile Iron, Cast Steel (WCB), or Stainless Steel.

2. Sealing for Zero-Leakage: Beyond Standard Packing

Because ammonia is a pungent and toxic gas, “acceptable leakage” does not exist. The sealing system must be over-engineered.

Bellows Seal Technology

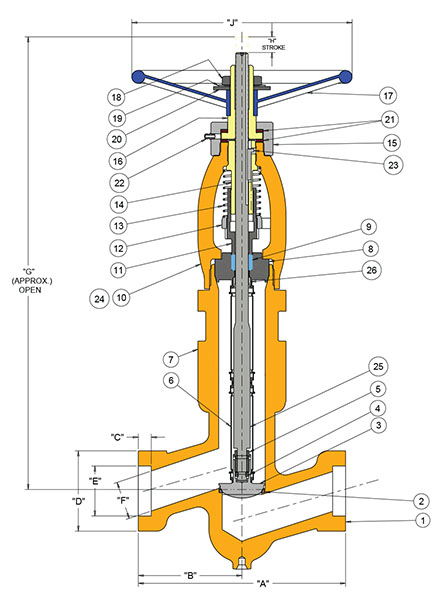

For critical ammonia lines, a Bellows Seal Globe Valve is the preferred choice. It uses a flexible metal bellows to create a hermetic seal, providing a permanent physical barrier between the ammonia and the atmosphere.

Double Packing Design

In high-pressure liquid ammonia service, we utilize a Deep Stuffing Box with double graphite or PTFE packing and a lantern ring. This ensures that even if the primary seal fails, the secondary seal prevents toxic release.

3. Low-Temperature Resilience

Anhydrous ammonia is often stored and transported at temperatures as low as -33°C (-27°F). Standard carbon steel can become brittle at these temperatures.

Impact Testing: Our globe valves for ammonia are manufactured from materials that undergo low-temperature impact testing to ensure they maintain their toughness and do not fracture under thermal shock.

Sealing at Cold Temps: We utilize specialized PTFE or Lead-free soft-seated designs that maintain flexibility and tight shut-off even in sub-zero refrigeration cycles.

4. Key Specifications for Ammonia Service

When reviewing your procurement list, ensure the valves meet these industrial benchmarks:

| Component | Required Specification | Why It Matters |

| Body Material | ASTM A352 LCB or A105/WCB | Ensures low-temperature ductility. |

| Trim Material | Stainless Steel (SS304/316) | Resistance to chemical attack. |

| Seat Type | Renewable PTFE or Hard-faced SS | Ensures bubble-tight shut-off. |

| Connection | Socket Weld or Flanged | Minimizes potential leak paths found in threaded joints. |

5. Compliance and Standards

Safety in ammonia systems is governed by strict codes. Our valves are designed to comply with:

IIAR (International Institute of Ammonia Refrigeration) standards.

ASME B31.5(Refrigeration Piping and Heat Transfer Components).

Safe Working Pressure (SWP) ratings of at least 300 psi (20 bar) for standard refrigeration cycles.

Conclusion: Expertise You Can Trust

A globe valve for ammonia is more than just a piece of hardware; it is a safety barrier. By choosing a valve specifically engineered for ammonia’s chemical quirks—no copper, low-temp toughness, and superior sealing—you protect your facility and your bottom line.