Table of Contents

ToggleThe Battle of the Isolation Valves

When it comes to isolating flow in large-scale piping systems, the debate usually boils down to two heavyweights: the Butterfly Valve and the Gate Valve. While both serve as shut-off valves, their mechanical designs and operational efficiencies are worlds apart.

Choosing the wrong one doesn’t just mean a leak—it means wasted energy, difficult maintenance, and premature system failure. This guide breaks down exactly which valve wins in different industrial scenarios.

I. At a Glance: Comparison Matrix

| Feature | Butterfly Valve | Gate Valve | Winner Based on Application |

| Operation | Quarter-turn (90°) | Multi-turn (Rising/Non-rising) | Butterfly (Speed) |

| Space/Weight | Compact & Lightweight | Bulky & Heavy | Butterfly (Space-saving) |

| Pressure Drop | Moderate (Disc in flow) | Extremely Low (Straight path) | Gate (Efficiency) |

| Cost | Lower (especially for >8″) | Higher | Butterfly (Budget) |

| Sealing | Resilient or Metal Seat | Metal-to-metal (usually) | Gate (High Pressure) |

| Standard | API 609 | API 600 / API 603 | – |

II. Why Size and Weight Are the “Game Changers”

In modern engineering, weight equals cost—not just in the valve itself, but in the supports and labor required to install it.

The Butterfly Advantage: A 12-inch butterfly valve is significantly thinner (wafer or lug type) and up to 70% lighter than a 12-inch gate valve. If you are working with limited space or overhead piping, the butterfly valve is the undisputed champion.

The Gate Valve Reality: Gate valves have a much larger “face-to-face” dimension. While this makes them robust, it also makes them difficult to install in tight skid-mounted systems.

III. Flow Performance: Pressure Drop (ΔP)

If your system is sensitive to energy loss, you need to look at the flow path.

Gate Valve (The Clear Path): When fully open, the gate is pulled entirely out of the flow. The fluid travels in a straight line with almost zero resistance. This is ideal for long-distance pipelines where you want to minimize pumping costs.

Butterfly Valve (The Obstacle): Even when fully open, the disc remains in the center of the flow. This creates turbulence and a permanent (though often minor) pressure drop.

IV. Operation and Speed: Manual vs. Automated

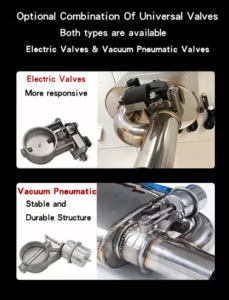

Butterfly Valve: Being a quarter-turn valve, it can go from fully open to fully closed in seconds. This makes it much easier and cheaper to automate with pneumatic or electric actuators.

Gate Valve: Requires multiple turns of the handwheel. While this prevents “water hammer” (by closing slowly), it is inefficient for systems requiring frequent or rapid cycling.

V. Critical Selection: Which One Should You Buy?

Choose a Butterfly Valve if:

You are working with large pipe diameters (above 8 inches).

Weight and space are restricted.

You need quick operation or frequent cycling.

The budget is tight, and the media is relatively clean (water, air, low-pressure liquids).

Choose a Gate Valve if:

You need bidirectional, bubble-tight sealing at high pressures.

Minimum pressure drop is your top priority for energy efficiency.

The media contains slurries or solids (Gate valves can “cut” through debris better than a disc).

The valve will remain open or closed for long periods without being cycled.

VI. Expert Verdict: Total Cost of Ownership (TCO)

While the initial purchase price of a butterfly valve is lower, consider the maintenance. Butterfly valve seats (resilient) are easier to replace, but gate valves can often be refurbished multiple times before the entire body needs replacing.

For High-Pressure Steam, we almost always recommend a Gate Valve or a High-Performance Triple Offset Butterfly Valve. For Water Treatment, the Resilient Seated Butterfly Valve is the global standard.