Table of Contents

ToggleThe Quarter-Turn Showdown

Ball valves and butterfly valves are the most popular choices for rapid shut-off and automation. While they share the same 90° operation, their internal designs lead to vastly different performance in high-pressure, high-cycle, or large-diameter applications.

This guide will help you determine the exact “break-even point” where one becomes superior to the other in terms of both performance and budget.

I. Structural Comparison: How They Handle Flow

1. The Ball Valve (Full Port Integrity)

A ball valve uses a spherical plug with a hole through it. When open, the flow path is completely clear (in Full Bore models).

Sealing: Provides the best possible seal for high-pressure gases and liquids.

Flow Resistance: Negligible. It is effectively a piece of straight pipe when open.

2. The Butterfly Valve (Compact Efficiency)

A butterfly valve uses a rotating disc supported by a central stem. Even when fully open, the disc remains in the flow stream.

Sealing: Great for low-to-medium pressure, but requires high-quality seats for critical shut-off.

Flow Resistance: Higher than a ball valve due to the disc’s obstruction.

II. The “6-Inch Rule”: Where the Choice Becomes Clear

If there is one thing that defines this comparison, it is size and scale.

| Metric | Ball Valve | Butterfly Valve |

| Size < 6″ | Winner. Superior sealing and lower maintenance. | Good, but ball valves are more reliable here. |

| Size > 6″ | Heavy and Expensive. Costs increase exponentially. | Winner. Extremely lightweight and cost-effective. |

| Weight Comparison | 12″ Ball Valve ≈ 400kg | 12″ Butterfly Valve ≈ 45 kg |

The Verdict: For small-diameter piping, the ball valve is the gold standard. For large-diameter pipelines, the butterfly valve is usually mandatory to reduce structural weight and project costs.

III. Performance Factors: Pressure, Temperature, and Slurries

1. Pressure Rating

Ball valves can handle pressures up to Class 2500 and beyond. Standard butterfly valves are typically limited to Class 150 or 300.

Exception: Triple Offset Butterfly Valves (TOV) can handle high-pressure critical service, but they are significantly more expensive.

2. Slurries and Solids

Ball Valves: Not ideal for abrasive slurries because particles can get trapped between the ball and the seat, causing scoring.

Butterfly Valves: Better for “dirty” media as the disc has a self-cleaning effect as it rotates, though high-velocity solids can erode the disc edge.

IV. Automation and Torque Requirements

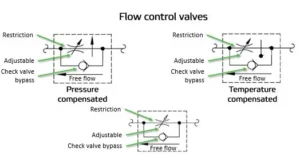

When it comes to actuation (pneumatic/electric), torque is the key metric.

Butterfly Valves: Require much lower torque to operate because the pressure is balanced on both sides of the disc stem. This means you can use smaller, cheaper actuators.

Ball Valves: High friction between the ball and the seats means they require higher torque, leading to larger and more expensive automation packages.

V. Quick Selection Checklist

Choose a Ball Valve if:

You need high-pressure or high-vacuum performance.

You require bubble-tight shut-off for gases.

You want zero flow resistance.

The pipe diameter is small to medium (< 6″).

Choose a Butterfly Valve if:

You are managing a large-diameter pipeline (> 6″).

Weight and space are at a premium.

The budget is a primary concern.

You need to regulate flow (Butterfly valves are slightly better at basic throttling than standard ball valves).

Conclusion: Balancing Performance and Budget

The decision between a ball valve and a butterfly valve often comes down to the pipe size and the pressure of the system. While the ball valve offers unparalleled sealing and flow capacity, the butterfly valve provides a lightweight, economical solution for large-scale utility and process lines.