Table of Contents

ToggleBreaking the Limitations of the Centerline

In modern piping systems, the butterfly valve is favored for its compact profile and rapid operation. However, traditional concentric (centerline) butterfly valves often hit a “performance wall” when facing high pressure, extreme temperatures, or abrasive media. The result? Rapid seat wear, massive operating torque, and frequent leaks.

The solution lies in the Eccentric Offset Structure. By shifting the axis of the stem and the disc, engineers have evolved the butterfly valve into a high-performance powerhouse capable of replacing gate and globe valves in critical services.

I. The Fatal Flaws of Concentric Design

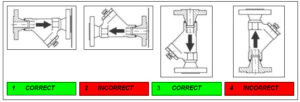

In a concentric valve, the stem travels through the exact center of the disc and seat. This creates a “surface-to-surface” friction seal.

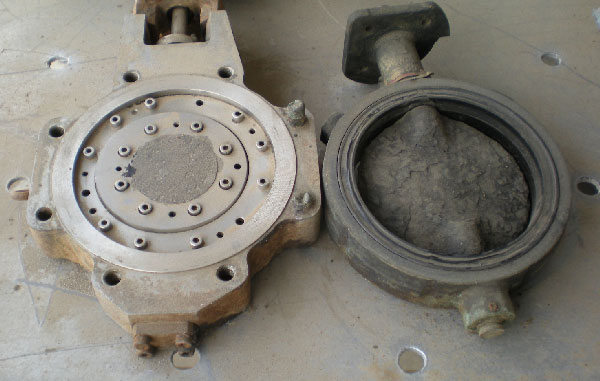

Severe Seat Wear: The disc rubs against the seat throughout the entire 90° travel, leading to “scuffing” and internal leaks.

High Torque: Overcoming the friction of a full-perimeter seal requires massive force, often overloading actuators.

Temperature Sensitivity: Soft rubber seats in concentric valves melt or deform above 200°C.

II. The 3 Pillars of Eccentric Advantage

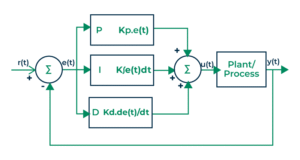

The transition to an eccentric butterfly valve isn’t just a design tweak; it’s a mechanical optimization that offers three key benefits:

Friction-Free Sealing: The disc “cam-lifts” off the seat instantly upon opening, reducing wear by over 60%.

Lower Torque Requirements: Eccentricity uses hydraulic leverage to assist opening. A double eccentric valve typically requires only 1/2 the torque of a concentric valve.

Extreme Condition Adaptability: These designs allow for metal-to-metal seals, pushing temperature limits to 600°C and pressure to PN100.

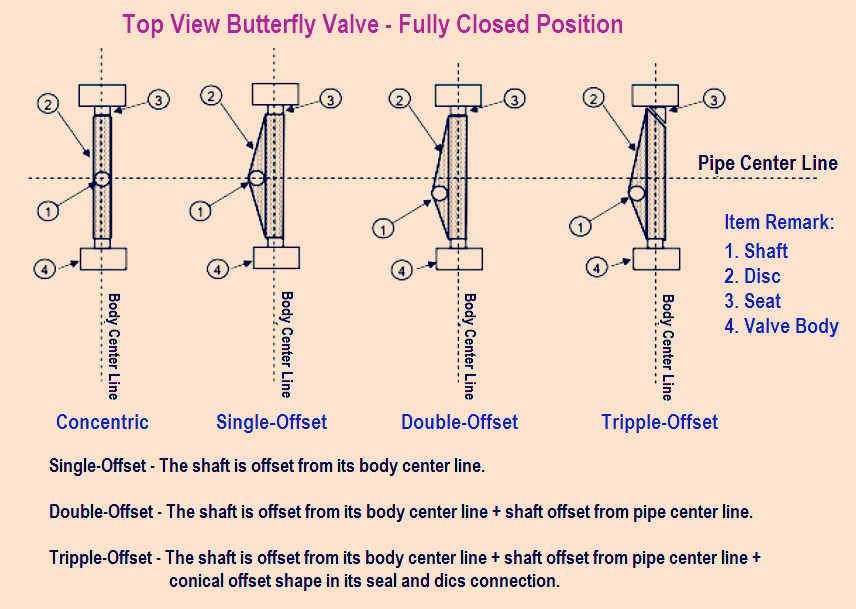

III. Comparing the Three Generations of Offsets

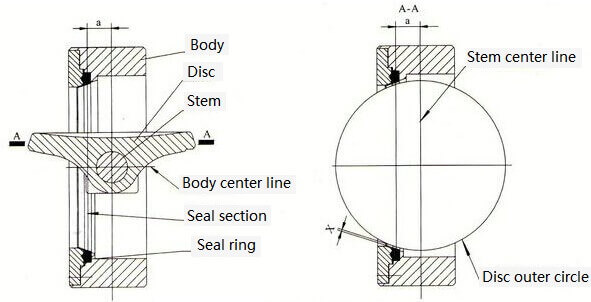

1. Single-Offset Butterfly Valve (The Basic Shift)

The stem is placed behind the centerline of the sealing surface.

The Result: The disc only makes contact with the seat during the final stages of closing.

Best For: Water treatment and HVAC systems where basic seat protection is needed but budgets are tight.

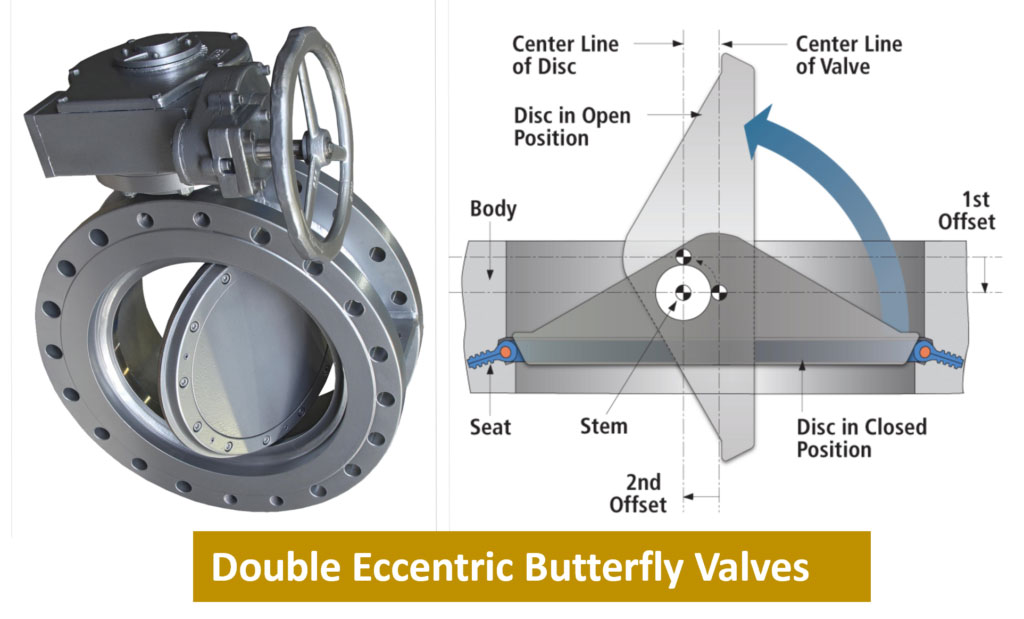

2. Double-Offset Butterfly Valve (The “High-Performance” Standard)

This design adds a second offset: the stem is shifted away from the center of the pipe.

The Result: The disc moves in an elliptical path. It completely clears the seat within the first few degrees of opening.

The Advantage: Enables the use of high-strength PTFE or fire-safe seats.

Application: Ideal for chemical processing, steam lines, and oil & gas (up to Class 300).

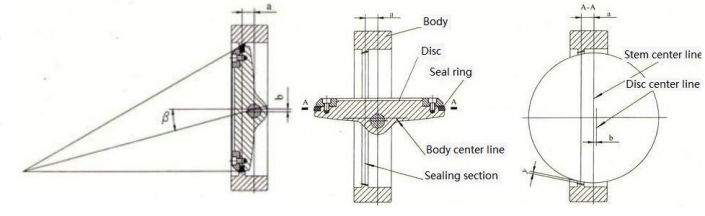

3. Triple-Offset Butterfly Valve (The “Zero-Leakage” Titan)

The third offset is a geometric tilt in the sealing cone, creating a unique “right-angled” seating geometry.

The Result: No friction at all until the final point of contact. The seal is achieved by mechanical compression rather than friction.

The Advantage: True bubble-tight (zero leakage) sealing. It is inherently fire-safe and excels in high-pressure/cryogenic extremes.

Application: Critical infrastructure, power plants, and refineries (up to Class 600 and beyond).

IV. Selection Guide: Matching Structure to Workload

Choosing the right offset is about balancing performance and total cost of ownership (TCO).

| Condition | Recommended Structure | Why? |

| Low Pressure / Clean Water | Concentric / Single Offset | Cost-effective and easy to maintain. |

| Steam / Corrosive Chemicals | Double Eccentric | Balances torque and durability. |

| High Temp / High Pressure / Abrasive Slurry | Triple Eccentric | Metal-to-metal contact prevents erosion. |

| Large Diameter (DN500) | Double or Triple Offset | To prevent actuator overload. |

Conclusion: Engineering for Longevity

The evolution from centerline to triple offset butterfly valves represents the “problem-solving” heart of industrial design. By understanding these eccentricities, plant managers can move away from “temporary fixes” and choose valves that offer years of stable, efficient operation.