Table of Contents

ToggleWhy “Standard” Isn’t Enough

In high-pressure and high-temperature environments, a standard concentric butterfly valve is a liability, not an asset. High performance butterfly valves (HPBV) were engineered to bridge the gap between the cost-efficiency of a butterfly valve and the ruggedness of a gate valve.

But as industrial standards like API 609 and ASME B16.34 evolve, how do you choose the right configuration for your 2025 projects? This guide dives deeper than basic definitions to explore the mechanical heart of high-performance flow control.

I. The Anatomy of Performance: Beyond the Surface

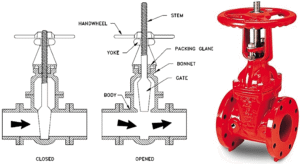

A valve earns the “High Performance” label through its internal geometry, not just its name. The core distinction lies in the Eccentric Offset Design.

1. Double Offset (High-Performance Standard)

The stem is displaced from the centerline of the seat and the disc.

The Mechanical Benefit: The disc “cams” off the seat within the first few degrees of rotation.

Service Life: This eliminates 90% of the friction that destroys soft seats (PTFE/RPTFE) in traditional valves.

2. Triple Offset (Zero-Leakage Excellence)

By adding a third, angular offset in the seating surface, the disc moves like a bolt into a nut—with zero contact until the final point of closure.

The Result: True Bubble-Tight (Class VI) sealing using metal-to-metal contact.

Best For: Extreme temperatures (up to 600°C) and high-pressure steam.

II. Material Science: Engineering for Longevity

In critical services, the material is the first line of defense. Athena Engineering mentions materials, but we provide the Selection Logic:

| Component | Standard Option | Critical Service Option | Advantage |

| Body | WCB (Carbon Steel) | CF8M / Duplex Steel | Corrosion resistance in acidic/saline media. |

| Seat | RPTFE (Soft) | Stellite-faced Metal | Resists erosion and “wire-drawing” in steam. |

| Stem | 17-4PH Stainless | Inconel 718 | High strength-to-weight ratio; prevents stem shear. |

III. The “Hidden” Metrics: What Engineers Must Check

To truly evaluate a high performance butterfly valve, look beyond the catalog’s front page:

Flow Coefficient (Cv): HPBVs offer higher Cv than globe valves of the same size, significantly reducing pumping energy costs over time.

Fire-Safe Certification (API 607): Does the valve have a secondary metal-to-metal seal that holds pressure even if the soft seat burns away?

Fugitive Emissions (ISO 15848): In 2025, environmental compliance is key. Look for live-loaded packing designs that minimize stem leakage to the atmosphere.

IV. Application Deep-Dive: Where HPBVs Rule

Why are these valves replacing traditional designs in major sectors?

Oil & Gas Refineries: Managing hydrocarbons at high velocities where traditional gate valves are too slow to automate.

LNG & Cryogenics: Specially extended bonnets and RPTFE seats ensure the valve doesn’t freeze or lose its seal at -196°C.

Power Generation: Acting as critical isolation valves for cooling water and low-pressure steam cycles.

V. Strategic Selection: How to Outperform the Competition

Don’t just buy a valve; buy a solution. Follow this 3-Step HPBV Audit:

Frequency of Operation: If you cycle the valve more than 50 times a day, only a Double Offset with a reinforced seat will survive.

Medium Purity: For “dirty” fluids or slurries, choose a Triple Offset with a hard-faced metal seat to prevent particle entrapment.

Space Constraints: Remember, a 12″ HPBV weighs approximately 70% less than a 12″ Gate Valve. If your support structure is limited, the HPBV wins every time.

Conclusion: Partnering for Performance

At tot valve, we don’t just supply high performance butterfly valves; we provide the engineering expertise to ensure they thrive in your specific environment. From cryogenic storage to high-temperature steam, our valves are tested to exceed API 609 standards.