High-Pressure Parallel Slide Gate Valve (Zero-Thermal Binding Design)

Essential Specs:

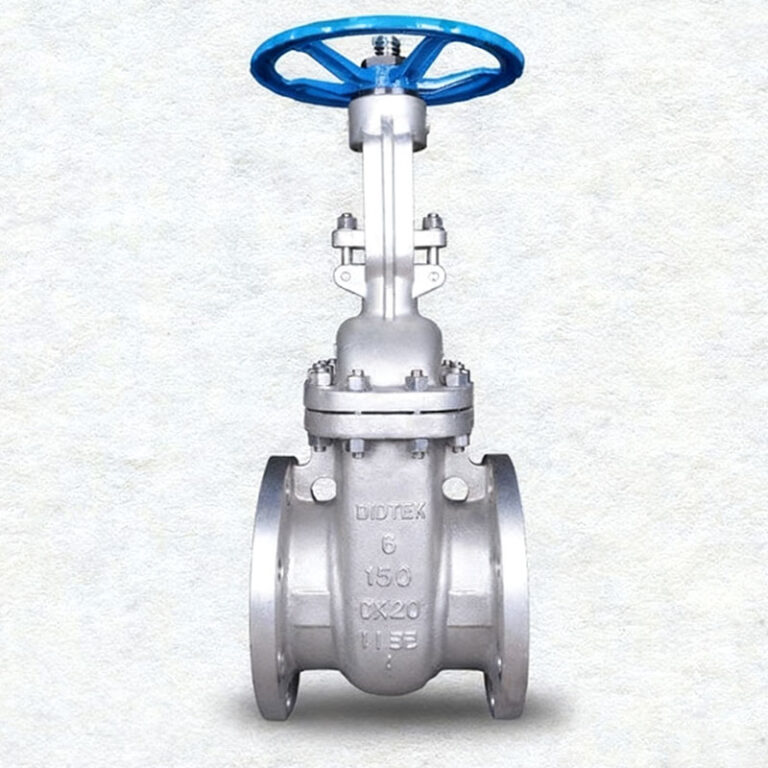

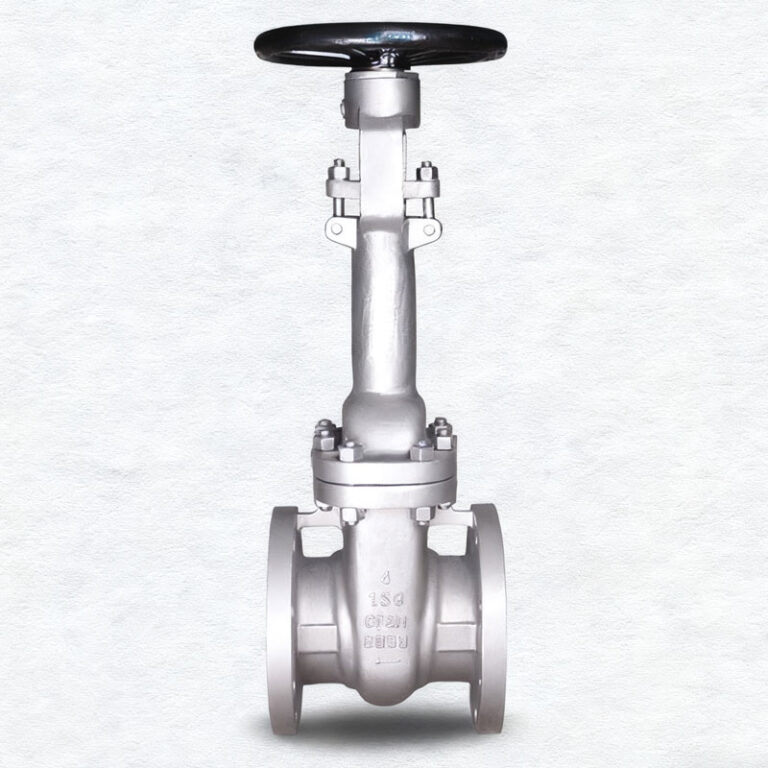

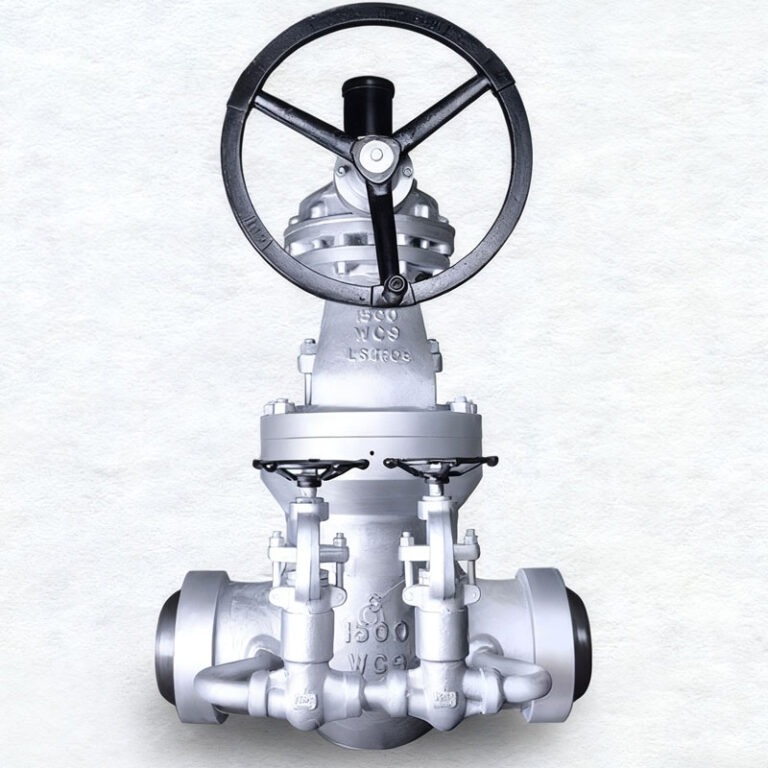

Design Standard: ASME B16.34 / API 600

Pressure Class: Class 600 – 4500 (PN100 – PN760)

Temperature Range: Up to 650°C (1200°F)

Body Materials: Forged/Cast Steel (WCB, WC6, WC9, C12A, F91)

Engineered to Eliminate Thermal Binding and Pressure Locking

In high-temperature steam applications, traditional wedge gate valves are prone to Thermal Binding—where the metal contracts upon cooling, jamming the wedge. Our Parallel Slide Gate Valve utilizes a position-seated, non-wedging design to ensure a reliable open/close cycle every time.

Core Advantages:

Zero Thermal Binding: The parallel disc design allows the valve body to expand and contract without affecting the operating torque or jamming the internals.

Pressure-Assisted Sealing: Sealing is achieved by the high-pressure media pushing the downstream disc against the seat, ensuring a bubble-tight seal that gets stronger as pressure increases.

Inherent Overpressure Protection: The upstream disc is designed to lift slightly if cavity pressure exceeds line pressure, providing automatic relief back into the pipeline.

Key Design Features

Self-Cleaning Sliding Action: The discs slide against the seat faces during every cycle, wiping away magnetite and scale to maintain a pristine sealing surface.

Spring-Loaded Initial Seal: A central spring ensures the discs maintain seat contact even at zero or low pressure, preventing debris from entering the seating area.

Full Stellite #6 Trim: All sealing surfaces are hard-faced with Stellite #6 to provide maximum resistance to erosion, wire-drawing, and high-velocity steam.

Pressure Seal Bonnet: Optimized for high-pressure service (Class 900+), using the internal pressure to tighten the bonnet seal.

Technical Specifications

| Feature | Standard Configuration | Premium Service Option |

| Size Range | 2″ – 36″ (DN50 – DN900) | Custom Large Bore |

| End Connections | Butt-Weld (BW) / Flanged | Custom Transition Pieces |

| Stem Seal | Live-loaded Graphite Packing | ISO 15848 Fugitive Emission Class |

| Disc Type | Two-Piece Parallel Slide | Single-piece spring-loaded |

| Operation | Handwheel / Bevel Gear | Pneumatic / Electric / Hydraulic |

Critical Service Applications

Main Steam Isolation (MSIV): Power plant boiler outlets and turbine inlets.

High-Pressure Feedwater: Critical isolation for boiler feed pumps.

Supercritical Cycles: Rated for 4500# service in ultra-supercritical coal and biomass plants.

Geothermal Energy: Handling high-temperature steam with minimal maintenance.

Compliant with: ASME B16.34, API 600, MSS-SP-144, and CE/PED.

Parallel Slide Valve: Frequently Asked Questions

Q: Can a Parallel Slide Valve be used for throttling?

A: While primarily designed for isolation, the parallel slide design handles intermediate positions better than wedge gates due to reduced friction; however, full isolation is the recommended primary use.

Q: How does this valve prevent “Pressure Locking”?

A: Unlike wedge valves that trap pressure in the bonnet, the parallel slide’s upstream disc can move slightly away from the seat under cavity pressure, venting it safely.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.