Table of Contents

ToggleSelection Defines Safety

When designing a fire service main, selecting the right indicator valve is about more than just passing an inspection—it is about ensuring absolute reliability during an emergency. Many procurement managers find themselves torn between a Vertical Post Indicator Valve (PIV) and a Wall Indicator Post.

This guide provides an in-depth comparison of these two primary configurations and explores best practices for high-stakes environments such as oil & gas, large-scale logistics, and corrosive coastal sites.

I. Core Comparison: Vertical PIV vs. Wall Indicator Post

While both serve the same fundamental purpose—providing visual confirmation of a valve’s status—their installation requirements and ideal environments differ significantly.

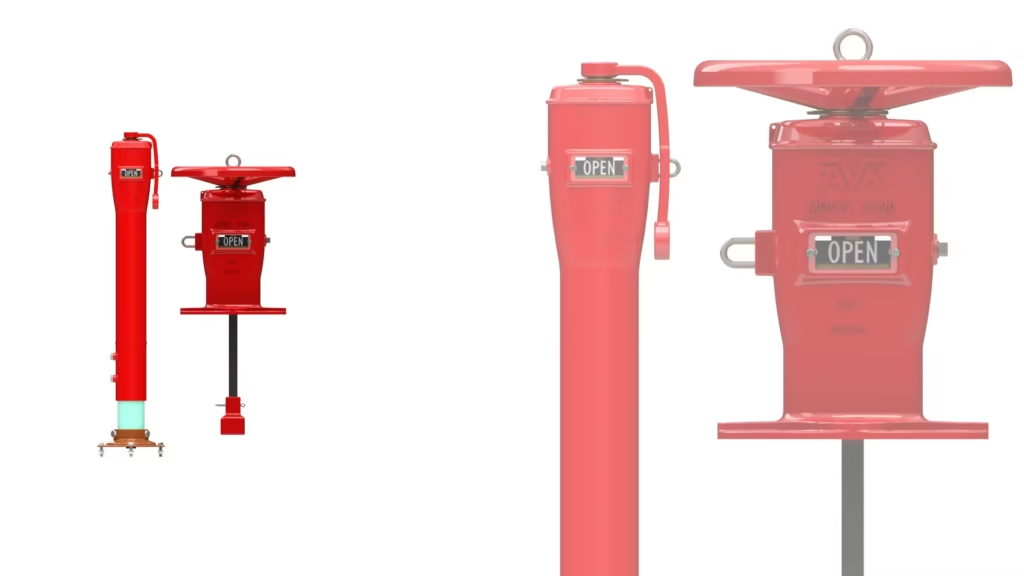

1. Vertical Post Indicator Valve (PIV)

Installation: Ground-mounted at a safe distance from the building (typically 40 feet or more).

Best For: Industrial complexes, large-scale warehouses, and chemical plants with ample exterior space.

Advantage: Maximum Safety. If the building collapses during a fire, the valve remains accessible in a safe zone. It is the gold standard for piv fire hydrant (isolation) systems.

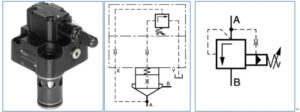

2. Wall Indicator Post

Installation: Mounted directly through the exterior wall of a building. The operating handle is outside, while the valve body remains inside.

Best For: Urban developments with limited ground space or pump rooms located against an exterior wall.

Advantage: Space-saving and protects the valve body from geological shifts or underground water corrosion.

II. The Critical Role of PIV in Hydrant Systems

When professionals search for piv fire hydrant or piv water, they are usually focused on system isolation.

In large industrial parks, a fire main indicator post is more than just an on/off switch; it is the key to sectional isolation:

Maintenance & Repair: If a specific segment of the fire loop or a hydrant leaks, the PIV allows you to isolate that section without de-pressurizing the entire facility’s fire protection.

Pressure Management: During system testing, PIVs allow for precise control of water flow, protecting sensitive indoor sprinkler heads from unnecessary pressure surges.

III. Severe Service: Why FBE Coating is Mandatory for Oil & Gas

For procurement officers in the petrochemical or coastal sectors, standard paint is insufficient.

1. Chemical Resistance with FBE

In chemical plants, the air often contains acidic or alkaline corrosive agents. Our fire post indicator valves are fully coated with Fusion Bonded Epoxy (FBE). This coating is thermally bonded to the metal, providing an impenetrable barrier against chemical attack.

2. Coastal Salt-Spray Protection

If your project is near the coastline, salt spray can quickly seize valve stems and cloud indicator windows. Our PIVs utilize stainless steel internal components and FBE coating to ensure that “OPEN/SHUT” targets remain crystal clear after years of exposure.

IV. Selection Matrix by Industry

| Industry Sector | Recommended Configuration | Why? |

| Logistics & Warehousing | Vertical PIV | Ample space; complies with NFPA 24 “distance-from-building” rules. |

| Urban Commercial Hubs | Wall Indicator Post | Zero footprint; allows fire crews to operate the valve from the sidewalk. |

| Oil, Gas & Chemical | Vertical PIV + FBE Coating | High corrosion resistance and clear isolation for hazardous zones. |

| Coastal Ports | SS316 Trim + FBE Coating | Prevents “stem-seize” from salt spray and humidity. |

Conclusion: Beyond the Hardware

Choosing a piv fire valve is about investing in long-term reliability. At tot valve, we provide more than just UL/FM Approved hardware—we deliver engineering solutions tailored to your site’s specific challenges.

Whether you are designing a fire loop for an oil refinery or a private service main for a distribution center, our technical team provides:

NFPA 24 compliant selection advice.

Custom bury depth configurations.

Comprehensive CAD installation details.