A Non Return Valve (NRV) is one of the most critical yet overlooked components in any fluid system. As the name suggests, its primary purpose is to ensure that the medium—whether it be water, gas, or oil—flows in a single direction and does not “return” or flow backward.

Often called a “one-way valve,” the NRV is a self-automated safety device that protects expensive equipment from damage. In this guide, we will explore the non return valve function, its various types, and how to choose the right one for your system.

Table of Contents

ToggleI. How Does a Non Return Valve Work?

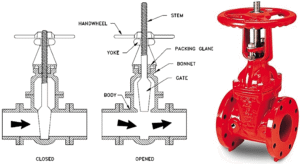

Unlike gate valves or ball valves, an NRV does not require a handle or an actuator to operate. It is “flow-dependent.”

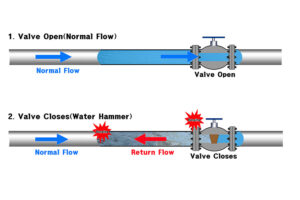

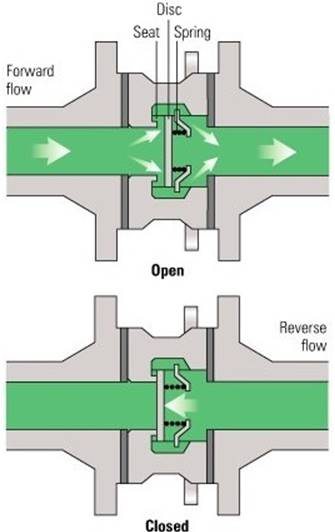

Opening: The valve opens when the pressure of the fluid coming from the upstream side exceeds the cracking pressure (the minimum pressure required to move the internal mechanism).

Sealing: When the pump shuts off or the flow reverses, the internal disc is pushed back against the valve seat by the reverse pressure (backpressure) and gravity, creating a tight seal.

II. Key Types of Non Return Valves

Depending on the viscosity of the fluid and the speed of the flow, different mechanical designs are used:

1. Swing Non Return Valve

Features a disc that pivots on a hinge. It is the most common choice for general water and wastewater applications because it offers very little resistance to flow when fully open.

2. Spring-Loaded In-Line NRV

Uses a spring to keep the valve closed until the cracking pressure is reached. These are excellent because they can be installed in any orientation (vertical or horizontal) and close very quickly, which helps prevent water hammer.

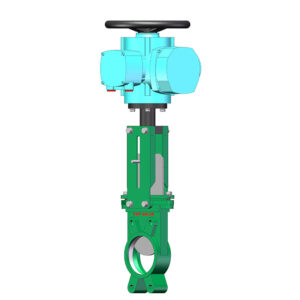

3. Dual Plate NRV (Wafer Design)

Common in industrial plants, this design uses two “butterfly” plates. It is much lighter and more compact than a standard swing NRV, making it easier to install between pipe flanges.

4. Ball Non Return Valve

Instead of a disc, a rubber-coated ball moves up and down. These are the preferred types of NRV for sewage and viscous fluids, as the ball rotates during operation, making it “self-cleaning” and less likely to clog.

III. Why Do You Need an NRV? (Core Functions)

Without a functioning non return valve, a piping system faces several risks:

Pump Protection: When a pump stops, the weight of the water in the vertical pipe can rush back and spin the pump in reverse, causing catastrophic mechanical failure.

Maintaining Prime: In suction systems, an NRV (often called a “Foot Valve” in this context) prevents water from draining out of the pump, ensuring it stays “primed” for the next start.

Preventing Contamination: In water systems, NRVs prevent “back-siphonage,” ensuring that contaminated water cannot flow back into clean water lines.

IV. Installation & Maintenance Tips

To ensure your non return valve lasts for years, follow these industry best practices:

Flow Arrow: Every NRV has an arrow cast into the body. This must point in the direction of the intended flow.

Horizontal vs. Vertical: Not all NRVs work vertically. A standard swing NRV usually requires gravity to close, meaning it works best in horizontal lines or vertical lines with upward flow.

Slamming & Water Hammer: If you hear a loud “thud” when the valve closes, it is “slamming.” Consider switching to a spring-assisted NRV or a “non-slam” design to protect your pipes from bursting.

V. Summary Checklist for Selection

When specifying a Non Return Valve, ensure you have the following data:

Medium: (Water, Steam, Chemical, or Sewage?)

Pressure Rating: (PN16, PN40, or ANSI 150/300?)

Connection: (Flanged, Threaded, or Wafer?)

Material: (Cast Iron, Stainless Steel, or PVC?)

Conclusion

The Non Return Valve is the silent guardian of your piping system. By understanding what is a non return valve and selecting the correct mechanical design, you can prevent expensive repairs and ensure smooth, one-way operations.