In a steam boiler, water evaporates into pure steam, leaving behind minerals, salts, and sediment. Over time, these impurities concentrate, forming scale on heat transfer surfaces or sludge at the bottom. What is a blowdown valve? It is the specialized device designed to eject these impurities, ensuring the boiler operates safely and maintains high steam quality.

Understanding the difference between surface blowdown and bottom blowdown is essential for any boiler operator or piping engineer.

Table of Contents

ToggleI. What is Blowdown in a Boiler?

Blowdown in a boiler is the process of intentionally removing a portion of water from the boiler to reduce the concentration of dissolved solids (TDS) and suspended sludge. Without a reliable boiler blowdown valve, these impurities would cause:

Scale buildup: Leading to overheating and tube failure.

Carryover: Contaminating the steam with water and chemicals.

Corrosion: Shortening the lifespan of the entire pressure vessel.

II. Surface Blowdown vs. Bottom Blowdown

There are two primary types of boiler blowdown methods, each requiring a different type of valve.

1. Surface Blowdown Valve (Continuous Blowdown)

The surface blowdown valve is located near the water line, where the concentration of dissolved solids and organic matter (like oil or foam) is highest.

Function: It provides “Continuous Blowdown” to maintain a steady TDS level.

Valve Type: Often a needle valve or a specialized control valve that allows for fine adjustment of the flow rate.

Benefit: Saves energy by removing only the necessary amount of water without massive pressure drops.

2. Bottom Blowdown Valve (Intermittent Blowdown)

The bottom blowdown valve is located at the lowest point of the boiler shell or mud drum.

Function: It is opened periodically (intermittently) for short bursts to blast out heavy sludge and scale.

Target Keywords:

bottom blowdown,blowdown valve for boiler.Design: These are usually heavy-duty boiler blowdown valves designed to handle high-velocity grit and “sandblasting” effects.

III. Common Boiler Blowdown Valve Types

Choosing the right blowdown valve steam boiler design is critical because standard valves will erode in weeks.

Quick-Opening Valves: Often used for bottom blowdown, these allow a sudden blast of water to stir up and remove sludge.

Seatless Valves: A specialized design where a plunger moves through a packing ring, ensuring there is no “seat” for scale to get trapped in and cause a leak.

Angle Blowdown Valves: The “angle” body design helps reduce the erosive impact of the blowdown media on the valve body.

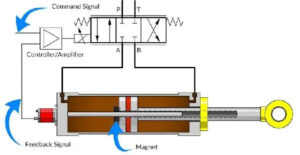

Automatic Blowdown Valve for Boiler: Modern systems use sensors to detect TDS levels and trigger an automatic blowdown valve, optimizing water and fuel consumption.

IV. Critical Maintenance: Why Blowdown Valves Leak

One of the most common issues is a boiler blowdown valve leaking. This usually happens because:

Scale Entrapment: A small piece of scale gets trapped between the disc and the seat.

Erosion: The high-velocity “flashing” of water into steam as it exits the valve can erode the metal (wire-drawing).

Improper Sequence: In systems with two valves in a row, if the wrong valve is opened first, it can damage the sealing surfaces.

V. Summary: How to Select a Blowdown Valve

When searching for a blowdown valve for sale, check these three things:

Pressure Rating: Does it meet ASME Section I requirements for your boiler’s pressure?

Operation: Do you need a manual lever or an automatic blowdown valve?

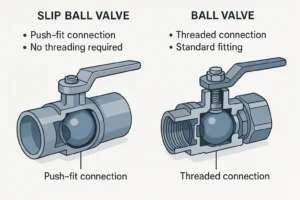

End Connections: Is your blowdown piping designed for flanged or socket-weld connections?

Conclusion

A blowdown valve is more than just a drain; it is a precision tool for water chemistry management. Whether you need to manage continuous surface blowdown or heavy-duty bottom blowdown, selecting the right boiler blowdown valve type will save thousands in energy and repair costs.